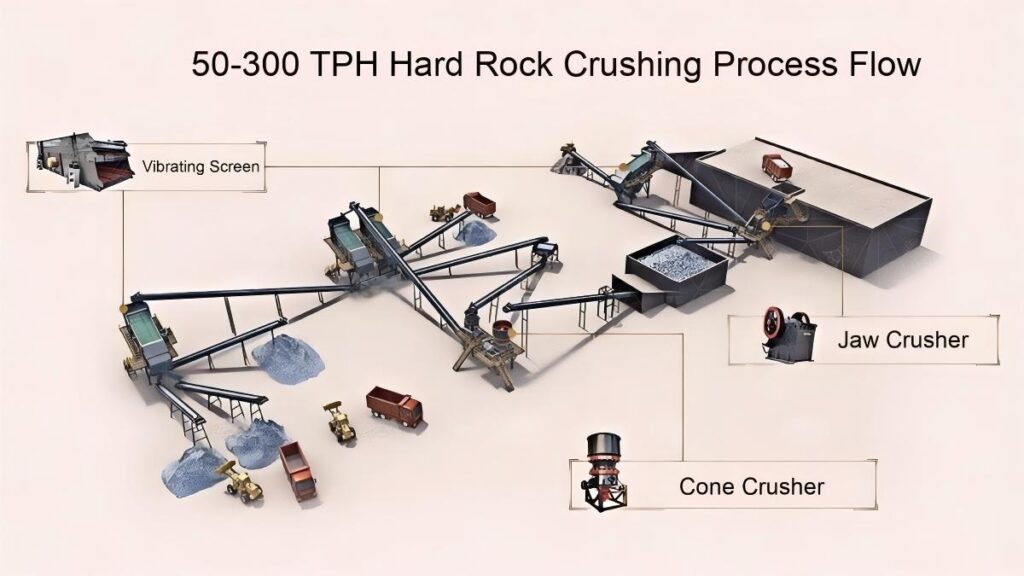

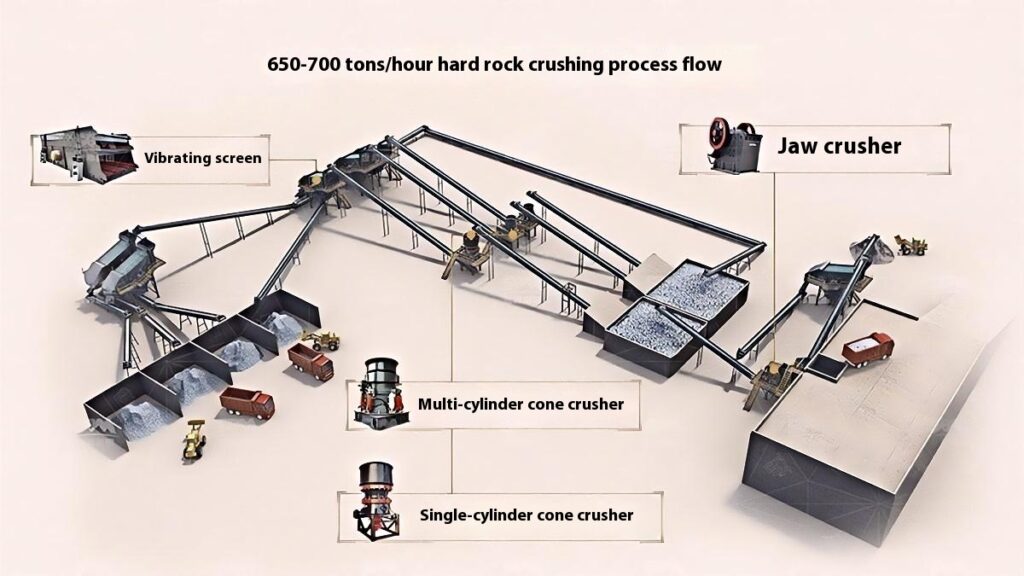

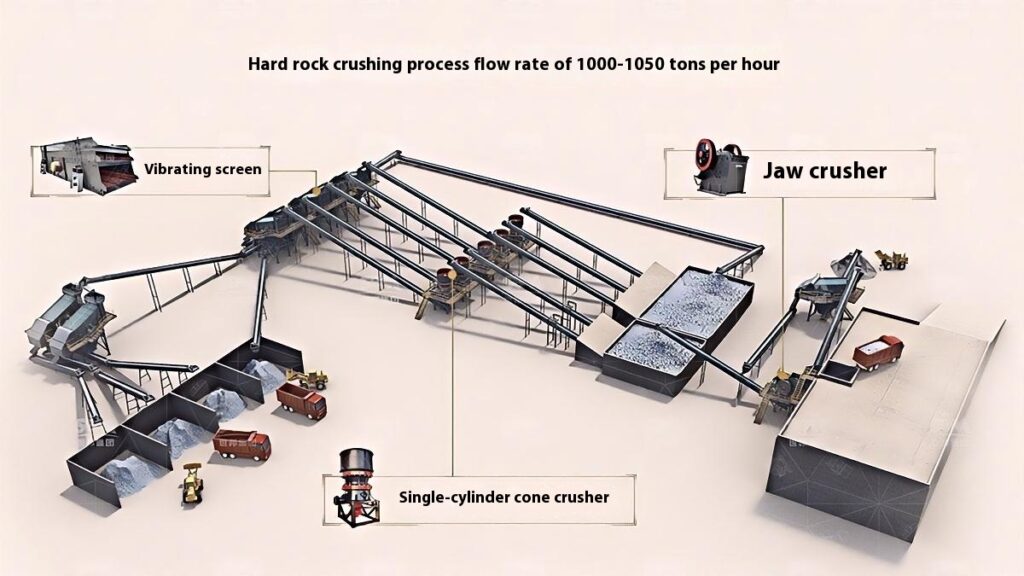

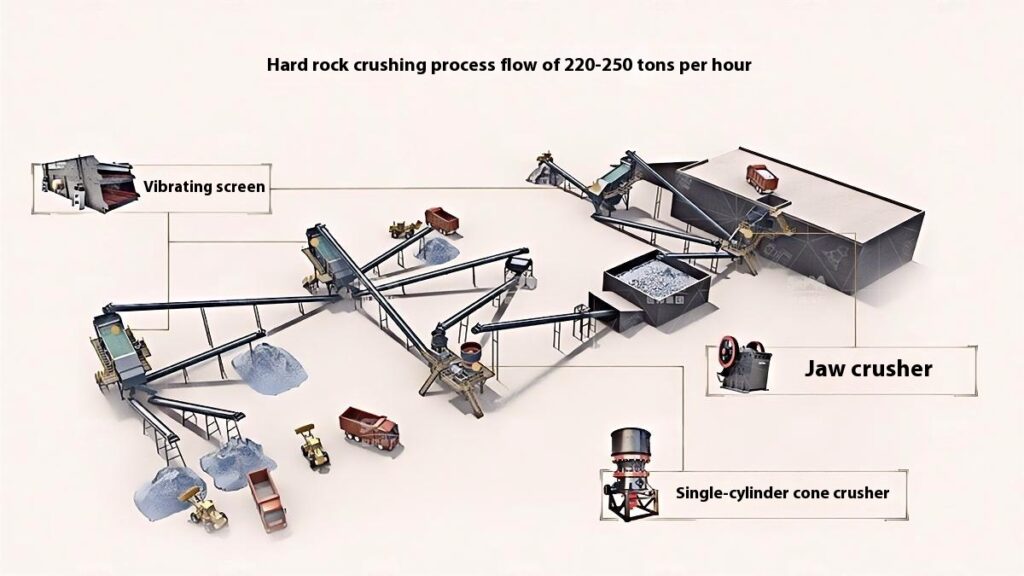

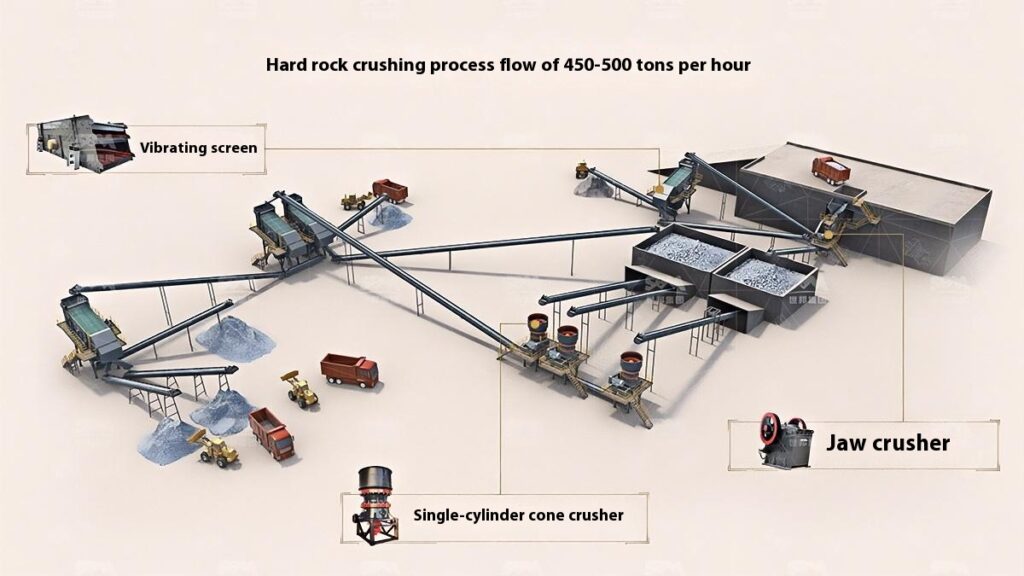

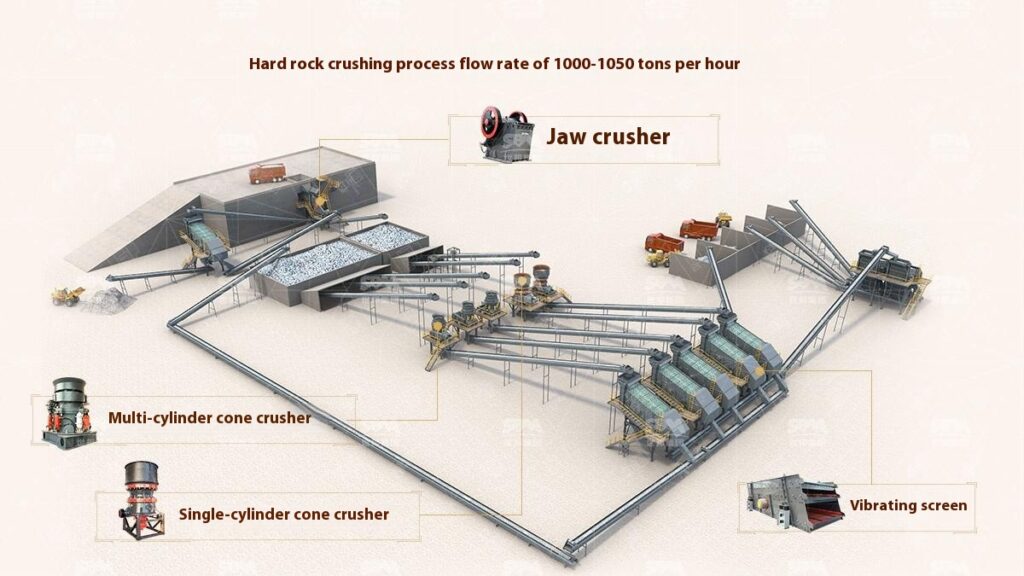

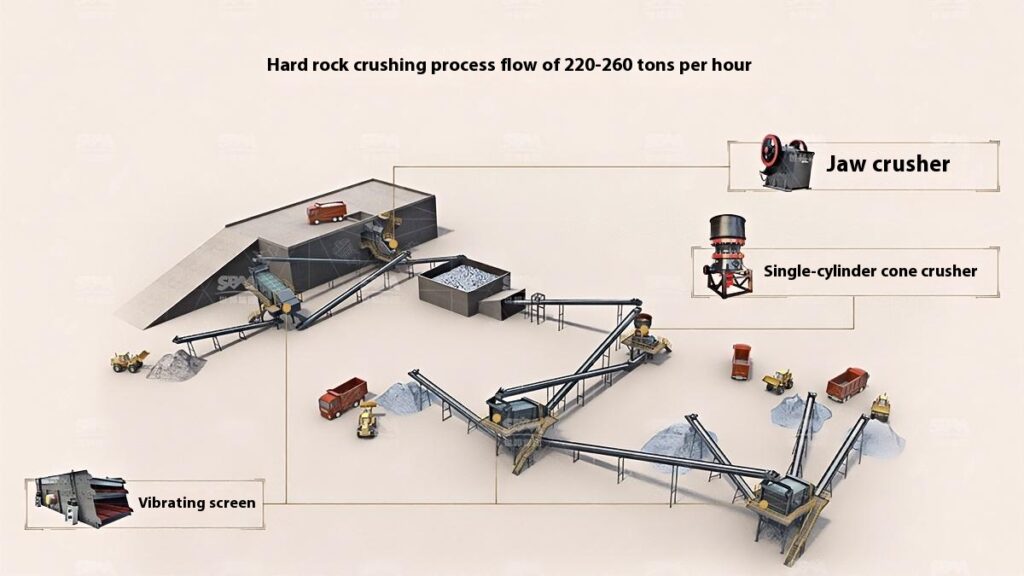

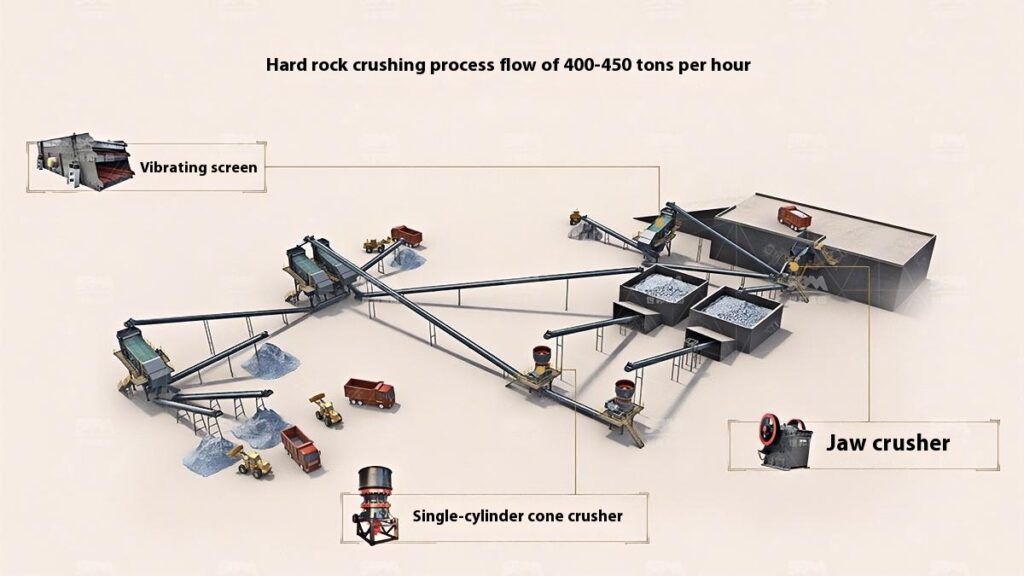

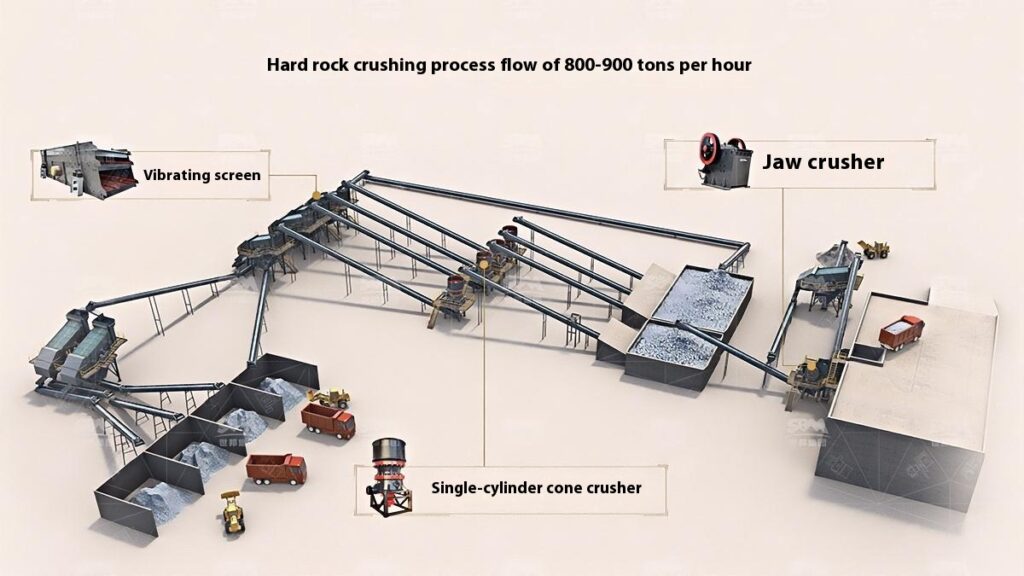

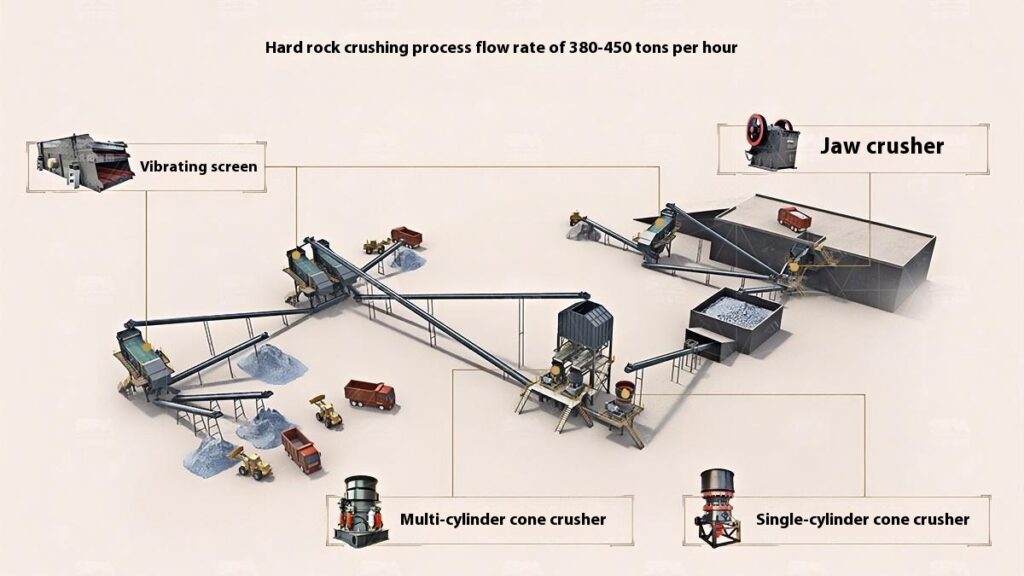

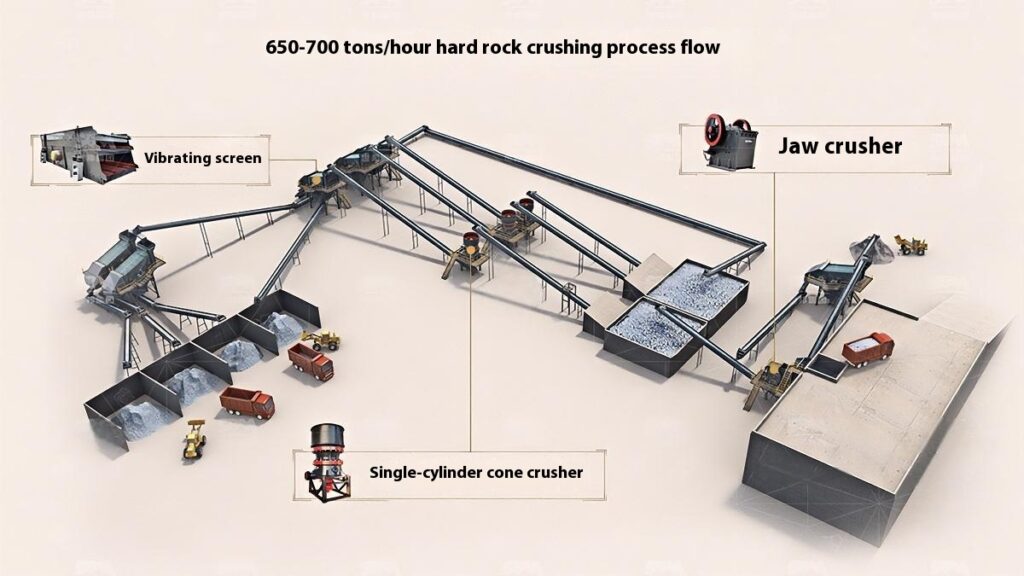

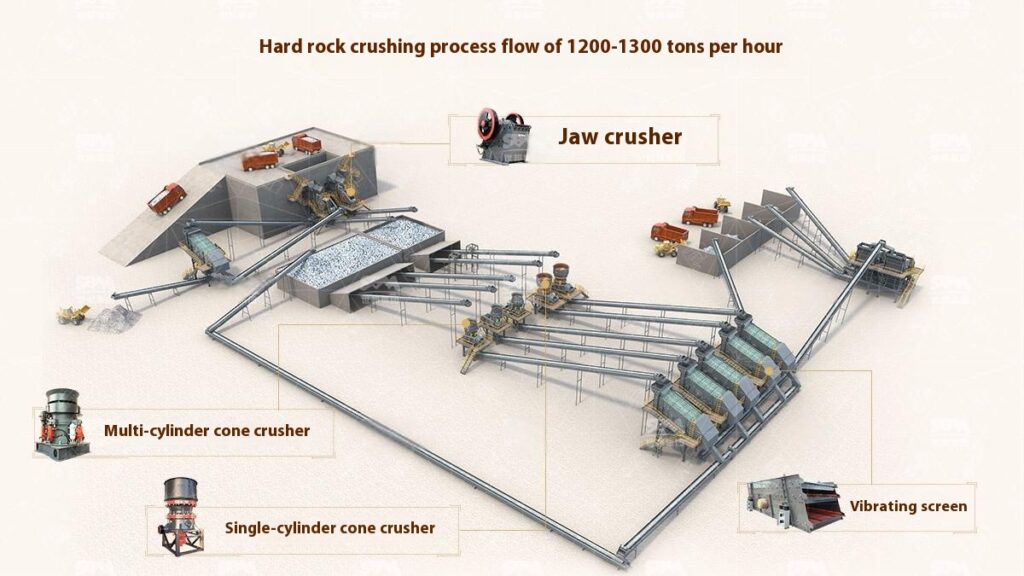

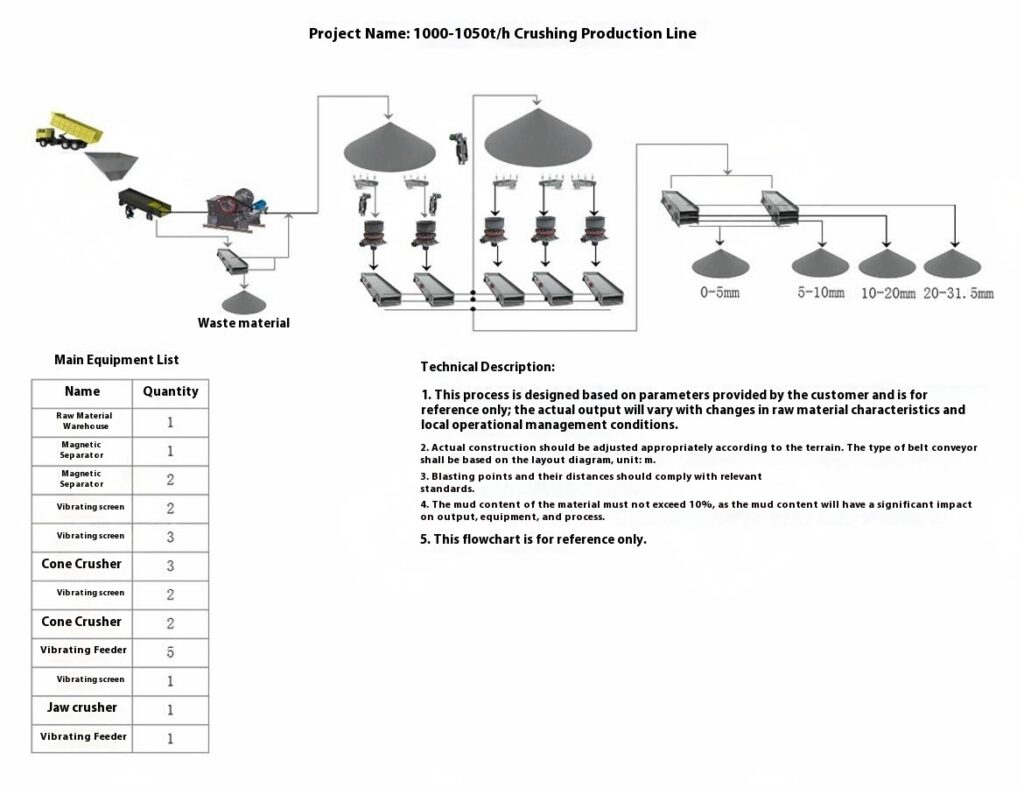

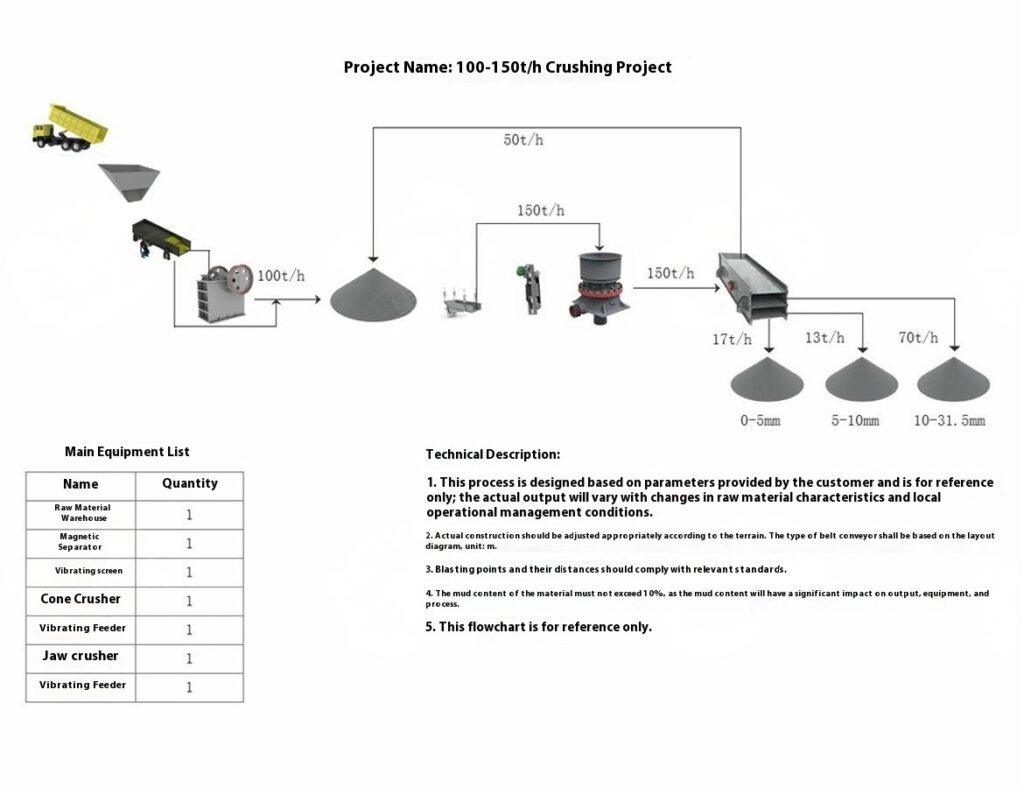

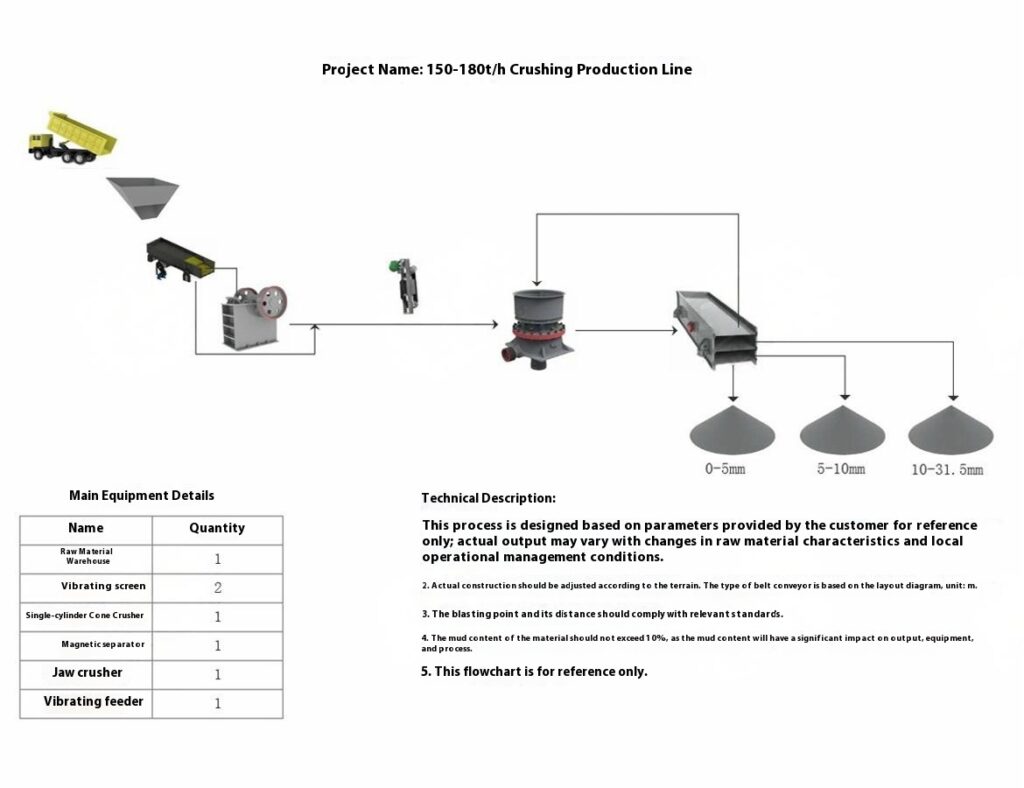

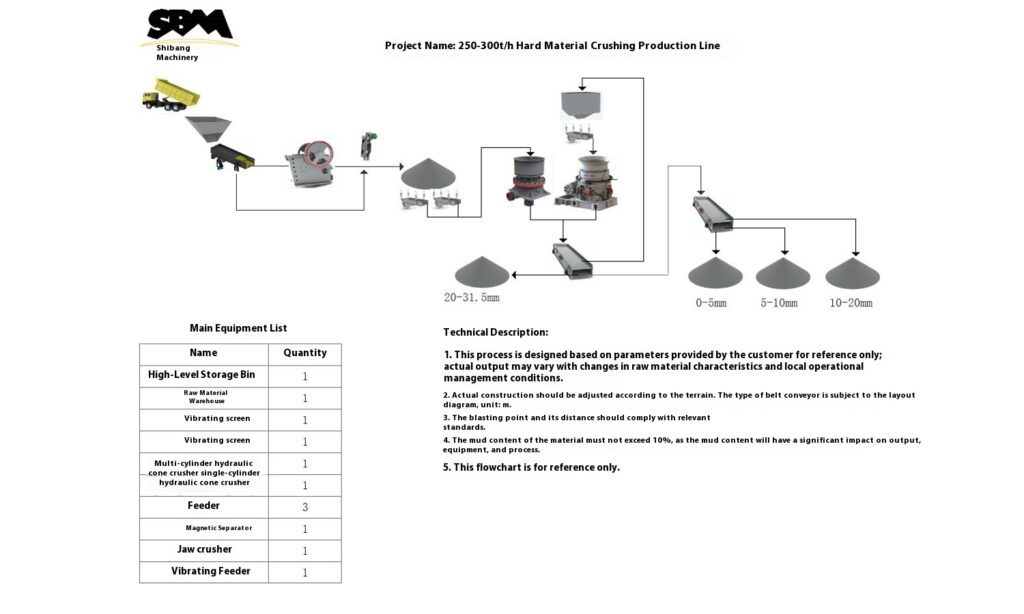

Design Scheme

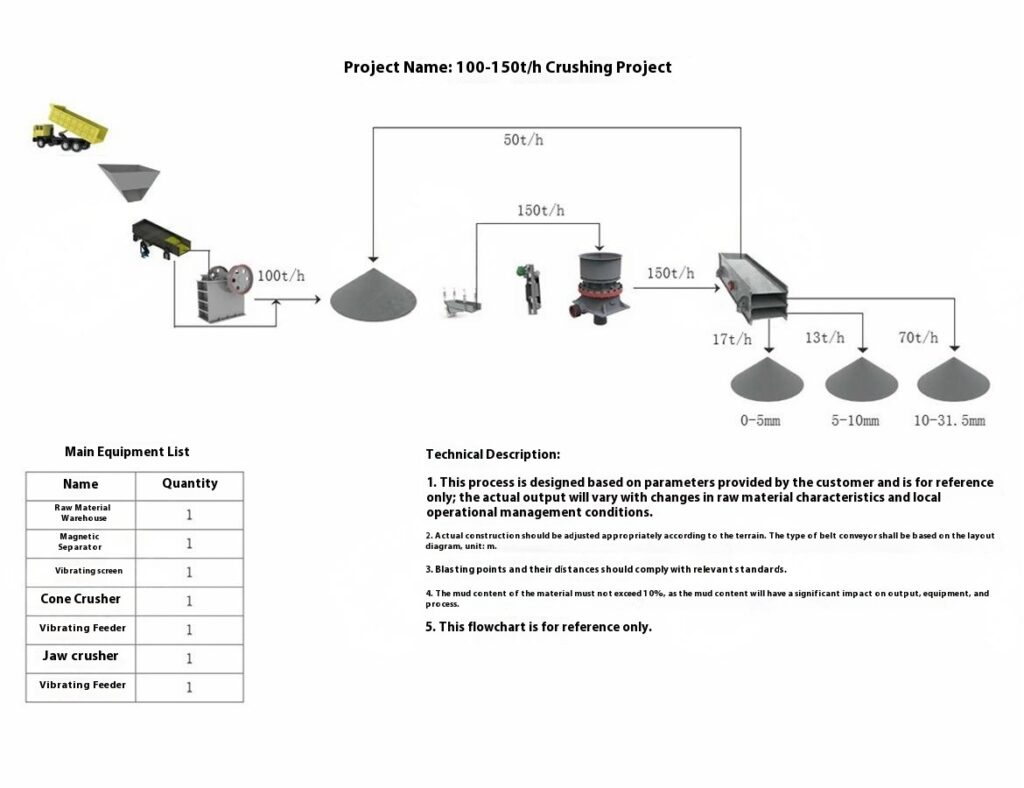

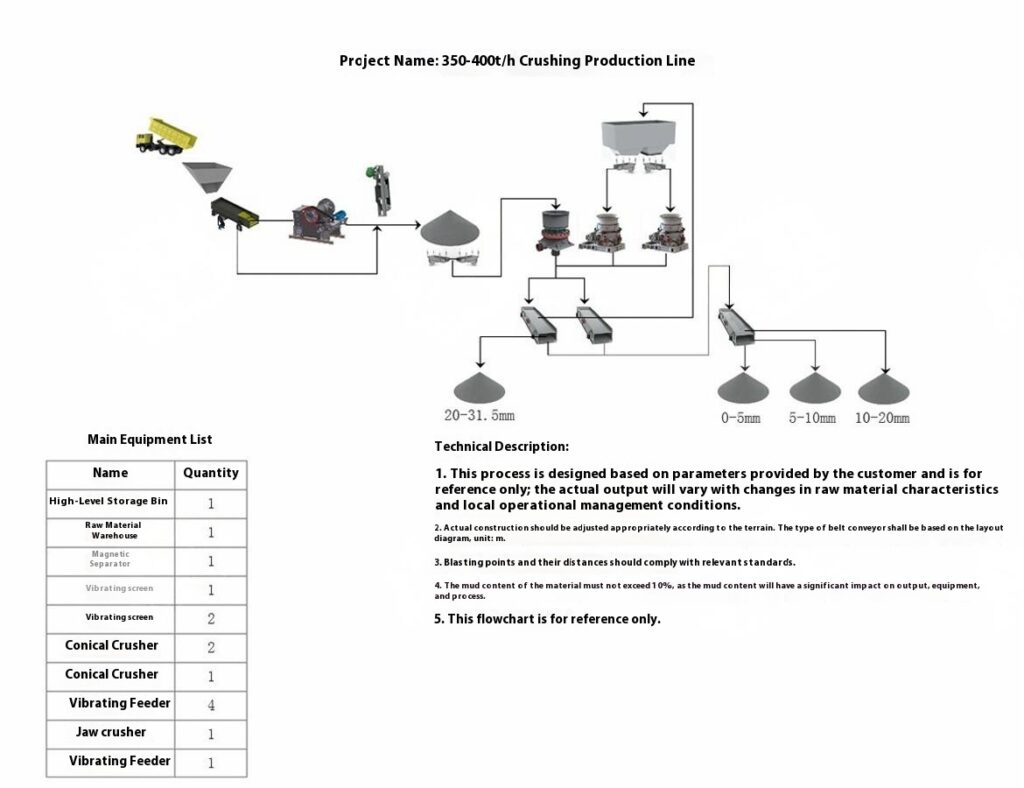

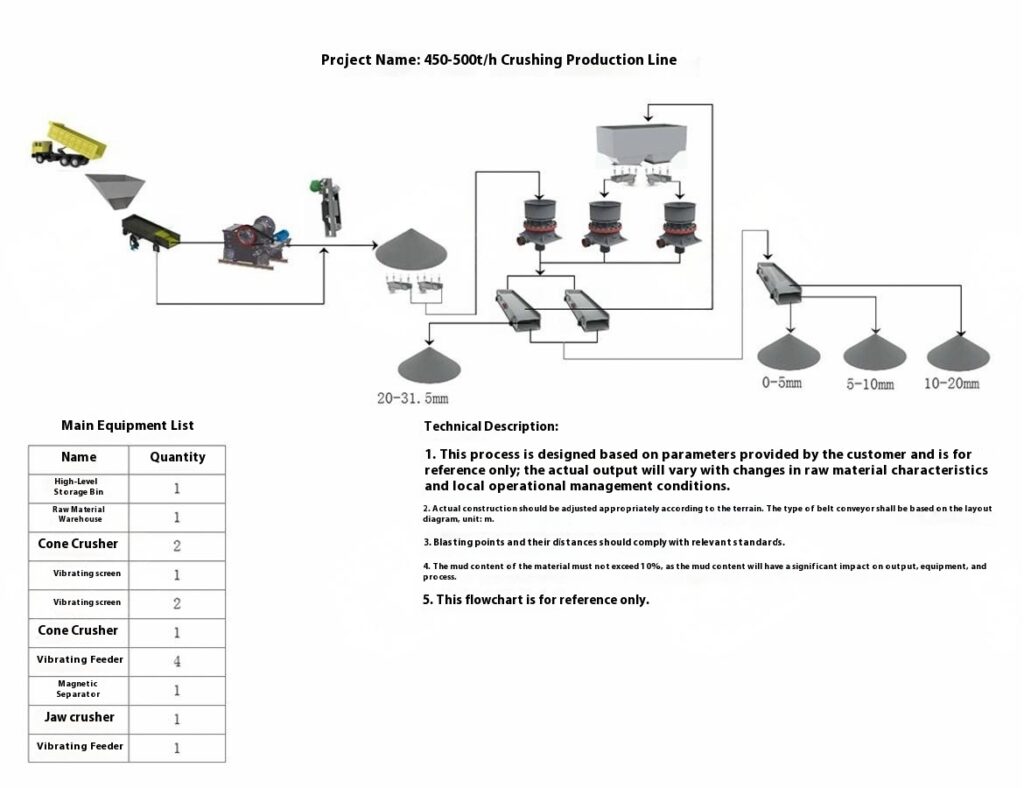

Construction Aggregates Crushing Process

Combined Crushing Process (Applicable to Railway Ballast, Basalt, River Pebble, หินแกรนิต, Feldspar, and Limestone)

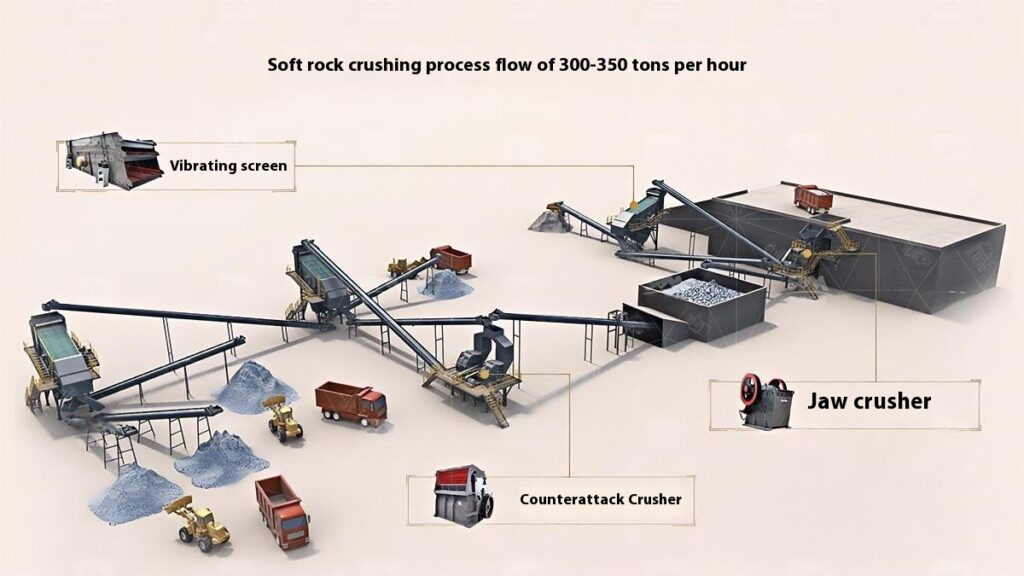

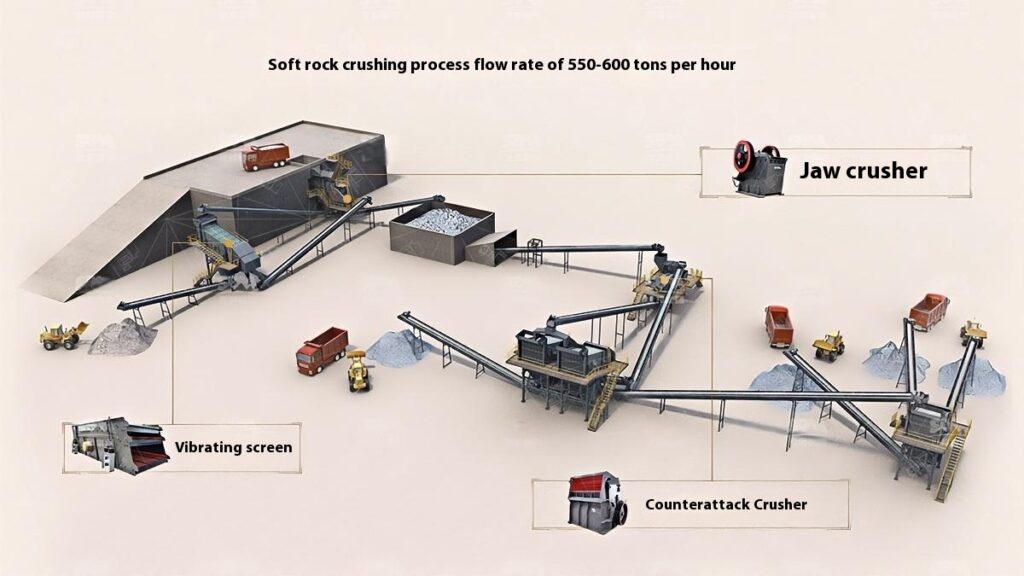

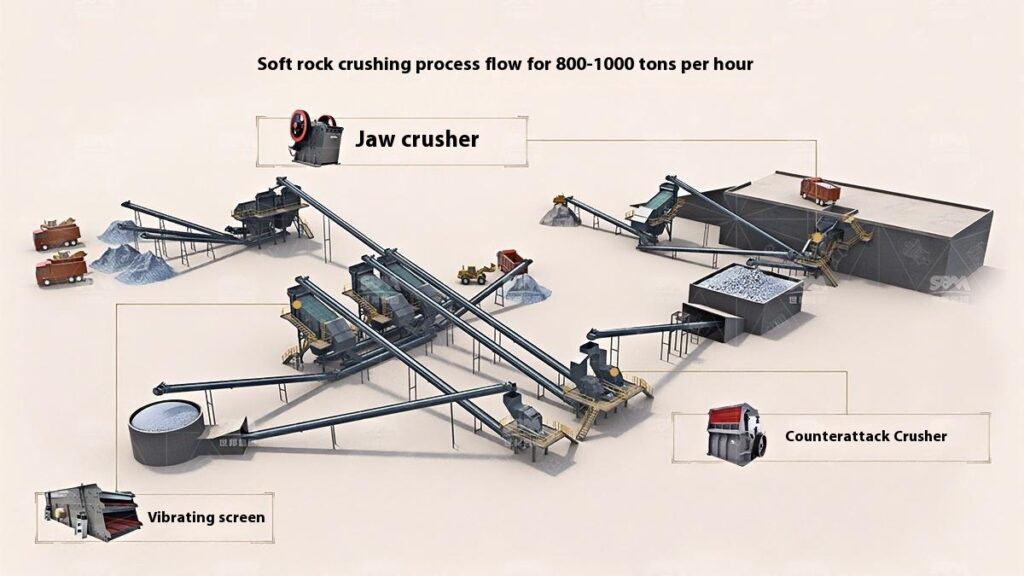

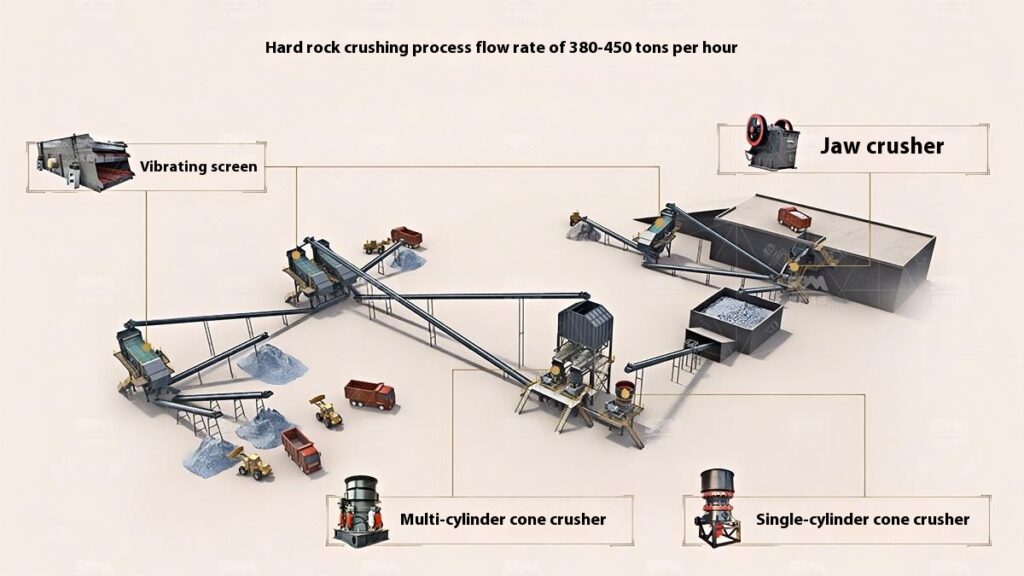

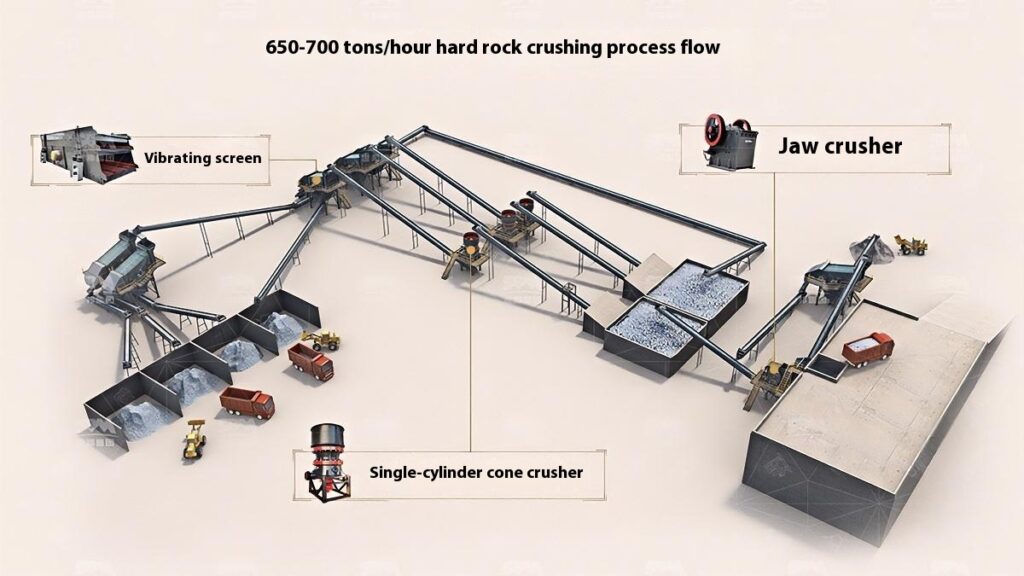

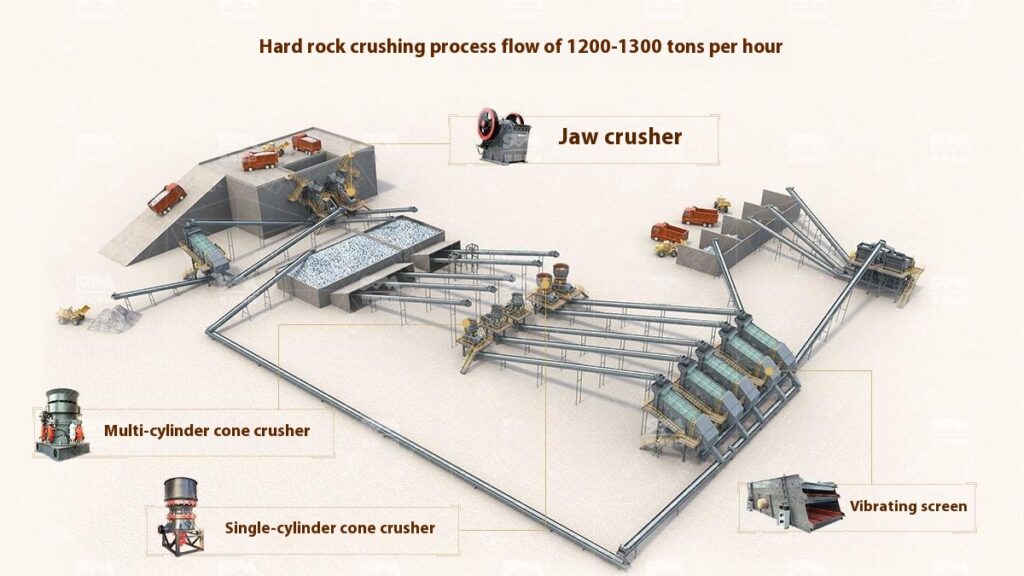

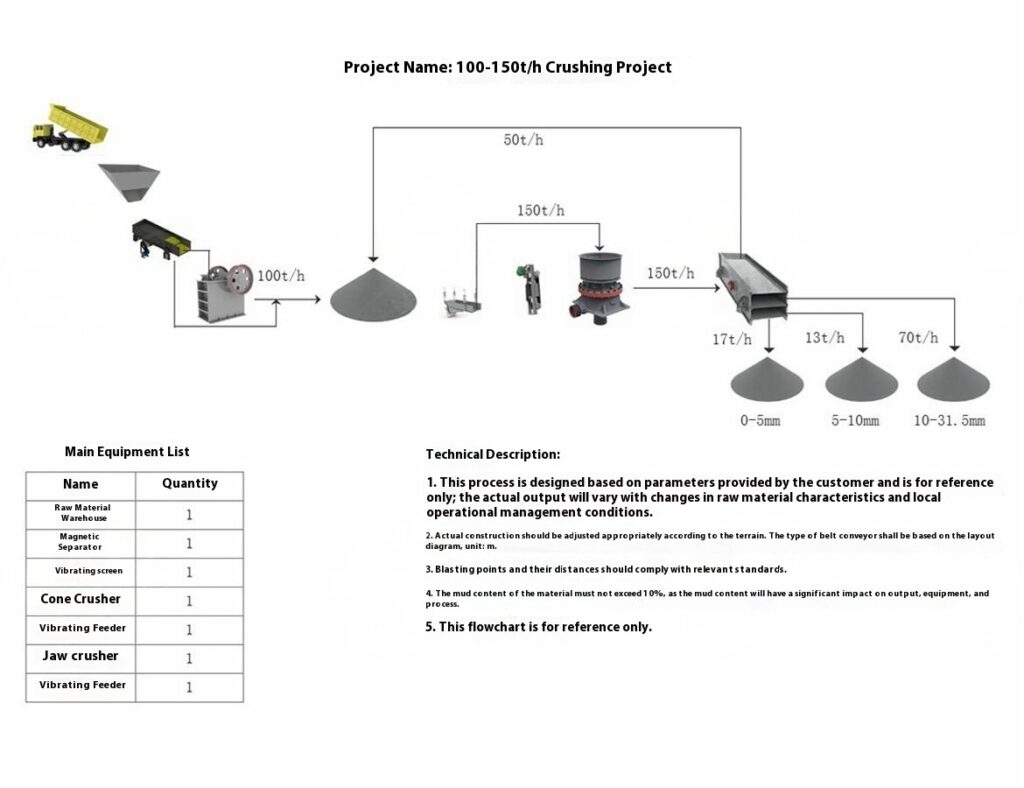

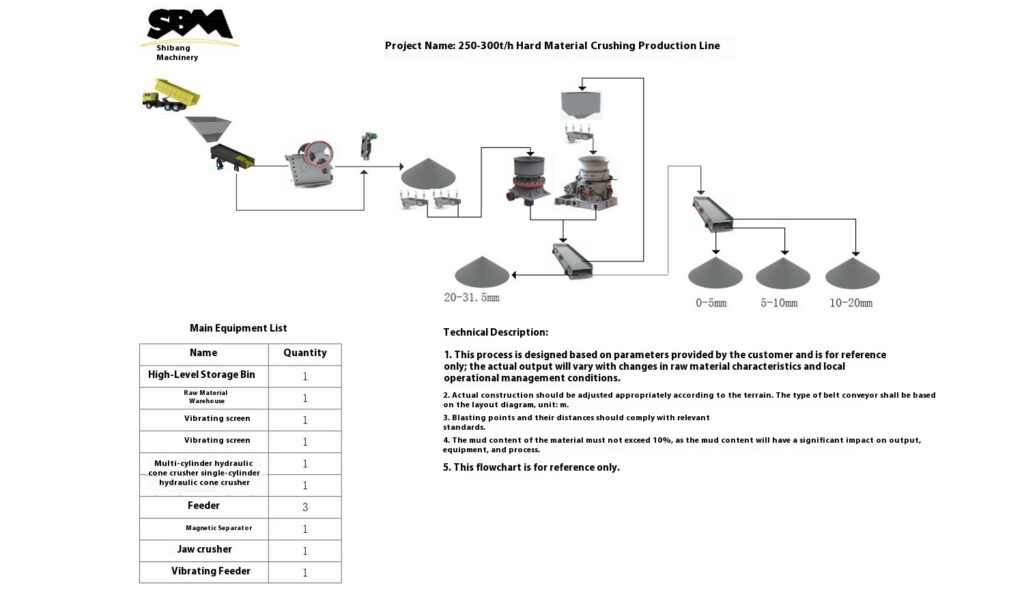

1. Raw Material Preprocessing

Use a vibrating feeder to ensure uniform feeding, maintaining stable operation of the equipment.

2. Primary Crushing

Use a jaw crusher for primary crushing to process large raw materials, achieving initial particle size reduction for subsequent processing.

Applicable to all types of stones for primary crushing.

3. Secondary Crushing

Select cone crusher or impact crusher for secondary crushing based on stone hardness and crushing requirements.

Hard stones such as basalt, granite, and feldspar mostly use cone crushers.

Softer stones or those requiring shaping, like railway ballast, river pebble, and limestone, mainly use impact crushers.

4. Screening and Classification

Use vibrating screens to classify the crushed materials, separating qualified products that meet the particle size requirements.

Unqualified materials are returned to the crusher for reprocessing to ensure consistent product quality.

5. Finished Product Stacking

Stack qualified finished products according to particle size specifications for easy transportation and further use.

Process Key Points

Ensure uniform feeding to avoid equipment blockage or overload.

Select appropriate crushing equipment to guarantee crushing efficiency and product quality.

Strictly control particle size during screening to ensure the shape and size of stone materials meet standards.

For hard stones such as basalt and granite, pay attention to equipment wear resistance.

Basalt

High hardness, dense structure, high compressive strength

Chemically stable, resistant to weathering

Typically dark gray or black in color

Basalt Crushing Process:

Raw material feeding → Primary crushing (jaw crusher) → Secondary crushing (cone crusher) → Vibrating screening and classification → Finished product stockpiling

Railway Ballast

High hardness and excellent wear resistance

Angular particle shape, ideal for stabilizing railway tracks

High compressive strength and good freeze-thaw resistance

Railway Ballast Crushing Process:

Feeding → Primary crushing (jaw crusher) → Secondary crushing (impact crusher or cone crusher) → Vibrating screening → Selection of products with required particle size → Oversized materials returned for re-crushing

Feldspar

High hardness, brittle nature

Dense structure with stable chemical properties

Available in various colors, commonly white, pink, or gray

Feldspar Crushing Process:

Feeding → Primary crushing (jaw crusher) → Secondary crushing (cone crusher or impact crusher) → Vibrating screening and classification → Finished product stockpiling

หินแกรนิต

Dense structure, high hardness, excellent wear resistance

Various colors, commonly gray, pink, or red

High compressive strength and strong weather resistance

Granite Crushing Process:

Feeding → Primary crushing (jaw crusher) → Secondary crushing (cone crusher or impact crusher) → Vibrating screening → Product classification

หินแกรนิต

Dense structure, high hardness, excellent wear resistance

Various colors, commonly gray, pink, or red

High compressive strength and strong weather resistance

Granite Crushing Process:

Feeding → Primary crushing (jaw crusher) → Secondary crushing (cone crusher or impact crusher) → Vibrating screening → Product classification

Limestone

Relatively soft texture with low hardness

Contains calcium carbonate, easily eroded by acidic substances

Typically light gray, white, or yellow with uniform texture

Limestone Crushing Process:

Feeding → Primary crushing (jaw crusher) → Secondary crushing (impact crusher) → Vibrating screening → Product classification → Oversized materials returned for re-crushing

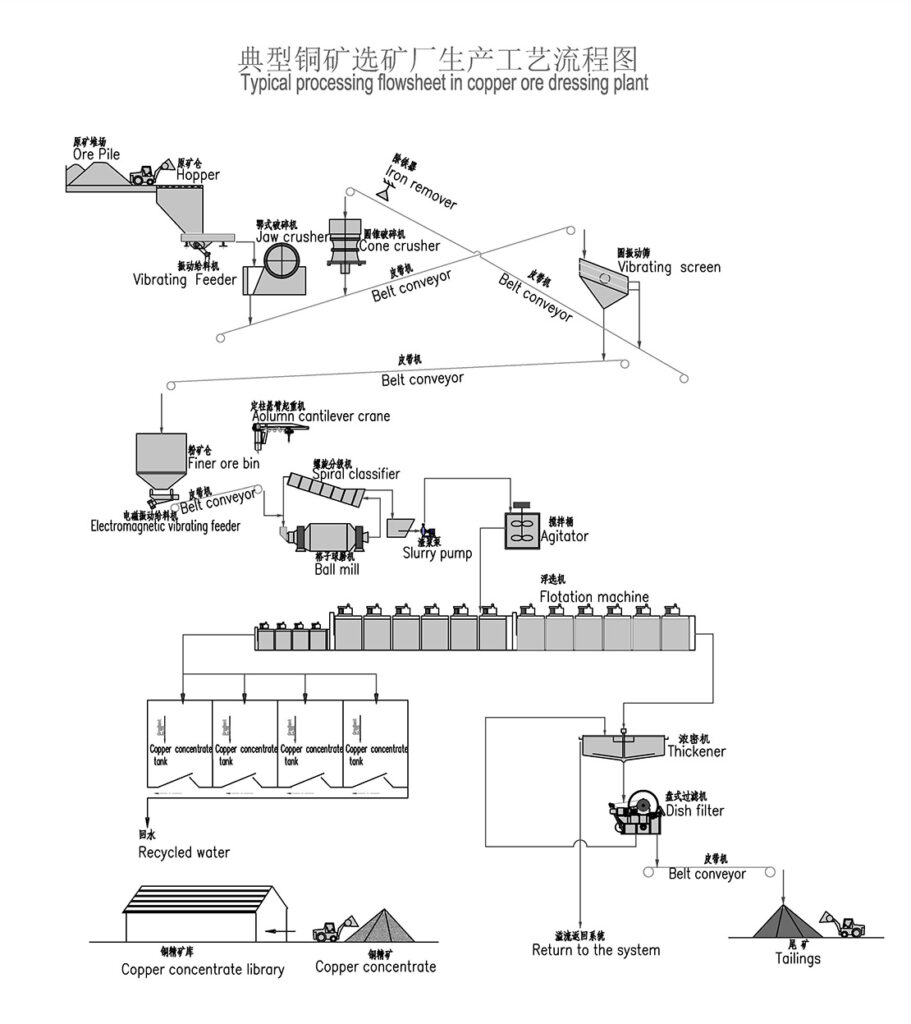

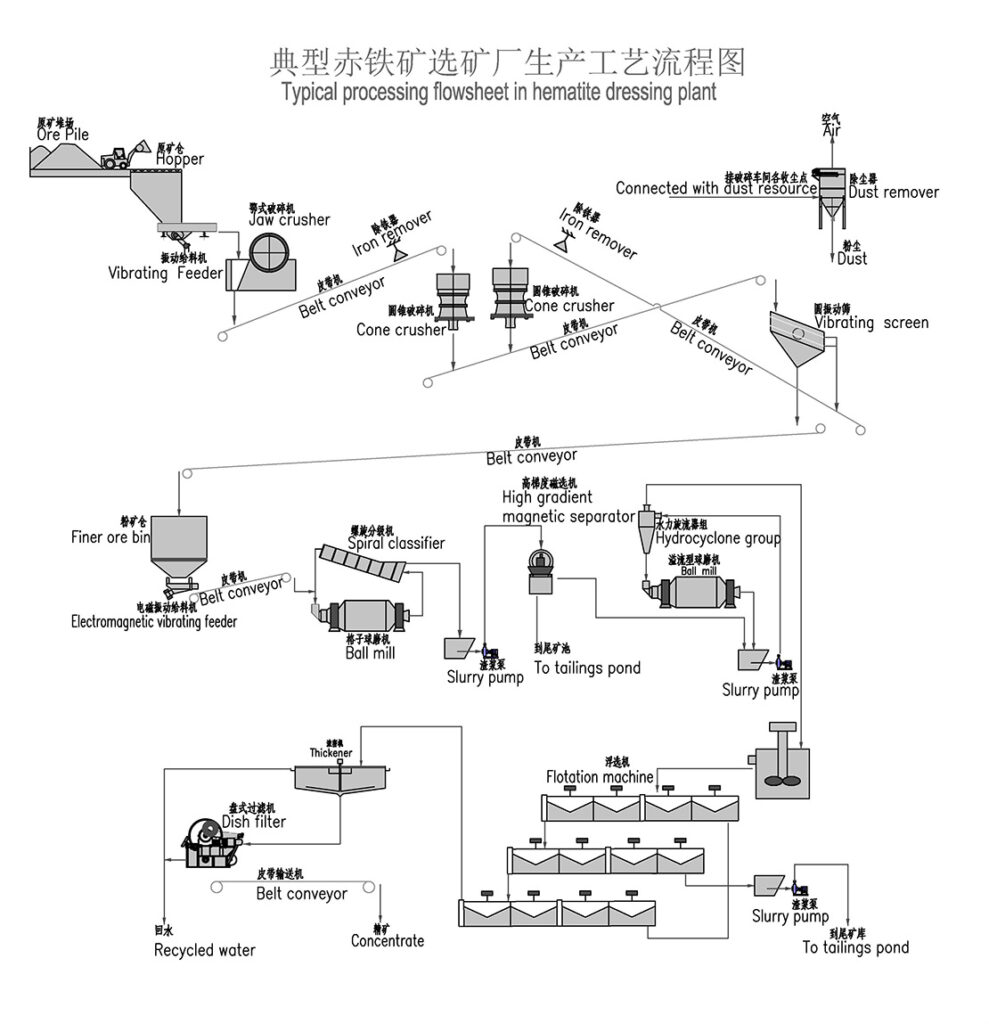

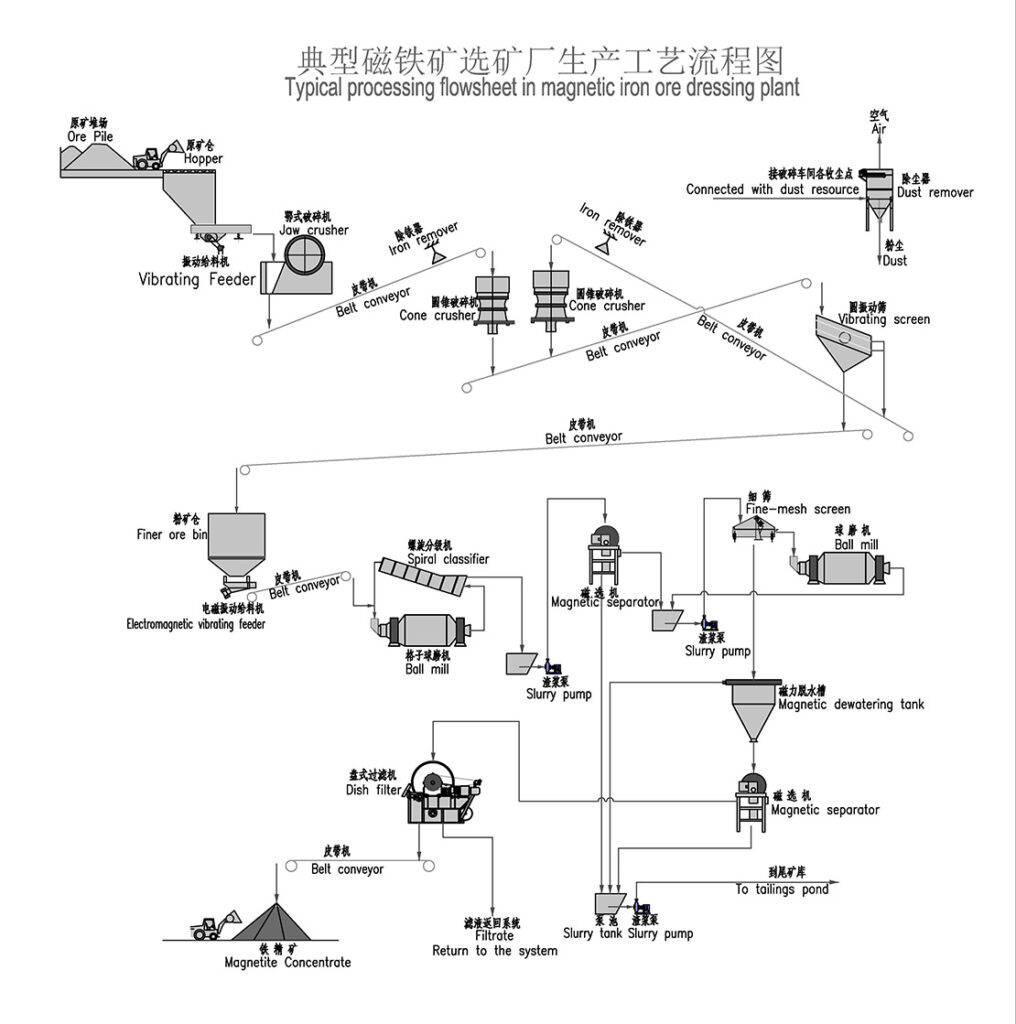

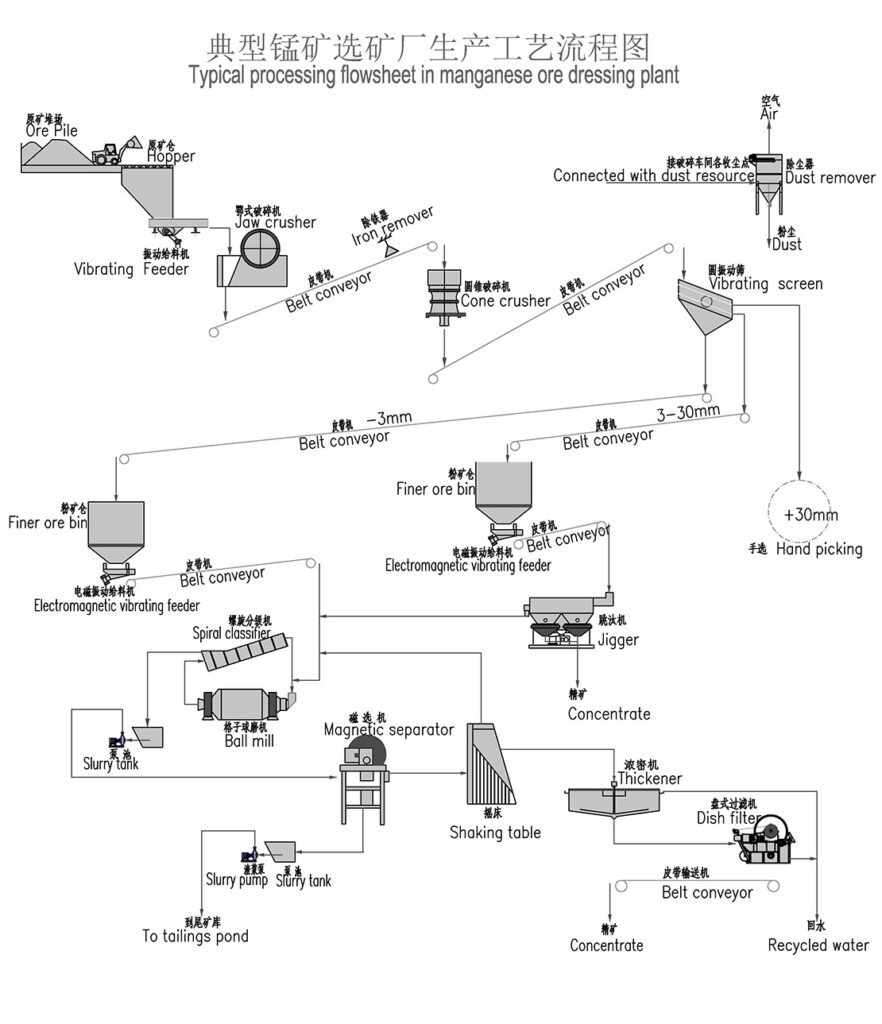

Non-Ferrous Metal Ore Crushing Process

Combined Crushing Process for Various Metal Ores

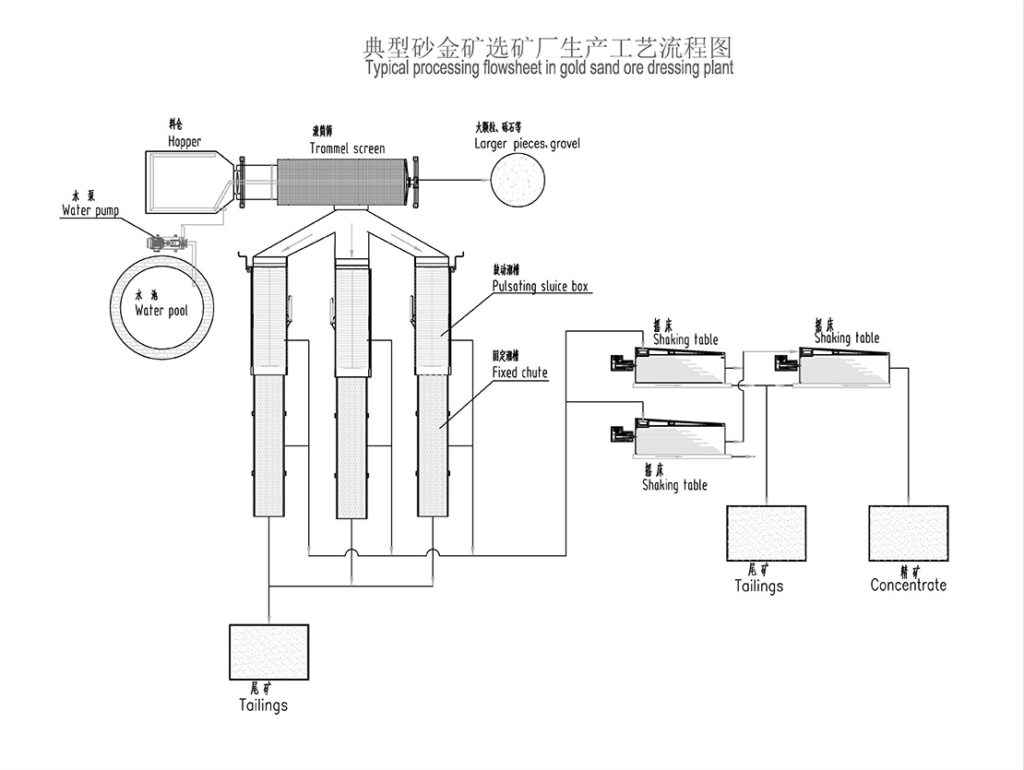

This combined crushing process is suitable for a variety of metal ores including hematite , manganese ore , magnetite , placer gold , gold ore , iron ore , copper ore , and copper ore rock .

1. Raw Material Feeding

Use vibrating feeders to ensure uniform, continuous feeding of ore materials into the crushing system for stable operation.

2. Primary Crushing

Large ore blocks are reduced in size by jaw crushers to facilitate further processing.

3. Secondary Crushing

Based on ore hardness and particle size requirements, cone crushers or impact crushers are employed for secondary crushing.

Hard ores like hematite, magnetite, and copper ores often use cone crushers.

Softer ores such as placer gold and some manganese ores may use impact crushers.

4. Screening and Classification

Vibrating screens classify crushed ore into different particle size ranges.

Oversized material is returned to crushers for further reduction, ensuring uniform product size.

5. Finished Product Stockpiling

Qualified crushed ore products are stockpiled by size for transport or further processing.

Process Highlights

Ensure uniform feeding to avoid equipment overload or blockage.

Select appropriate crushers based on the ore’s hardness and abrasiveness.

Maintain strict control on particle size through screening to ensure product quality.

Use wear-resistant equipment components to handle the abrasive nature of metal ores, improving equipment life.