Stone Washing Machine – Types, Features, and Applications

A stone washing machine, also known as a sand washing machine or sand washer, is widely used in construction sites, sand and gravel plants, prefabrication plants, and hydropower projects for large-scale sand and stone washing, dewatering, and screening operations. It can also be used in ore beneficiation processes to remove impurities.

These machines are designed to clean excavated sand and gravel, removing mud, dust, and other unwanted materials using water. After extraction from riverbeds or rock layers, raw materials often contain high levels of impurities. The stone washing machine uses water flushing, tumbling, and vibration to separate dirt from clean aggregates, achieving a purifying effect.

Main Types of Stone Washing Machines

Stone washing machines come in several designs, each suited for specific applications:

- Spiral Stone Washer – Uses spiral blades to push and agitate materials, separating them from water and mud. Produces clean aggregates but has slightly lower output.

- Trommel Stone Washer – Uses a rotating drum to tumble stones, combined with high-pressure water jets for cleaning. Requires more water but offers high production capacity.

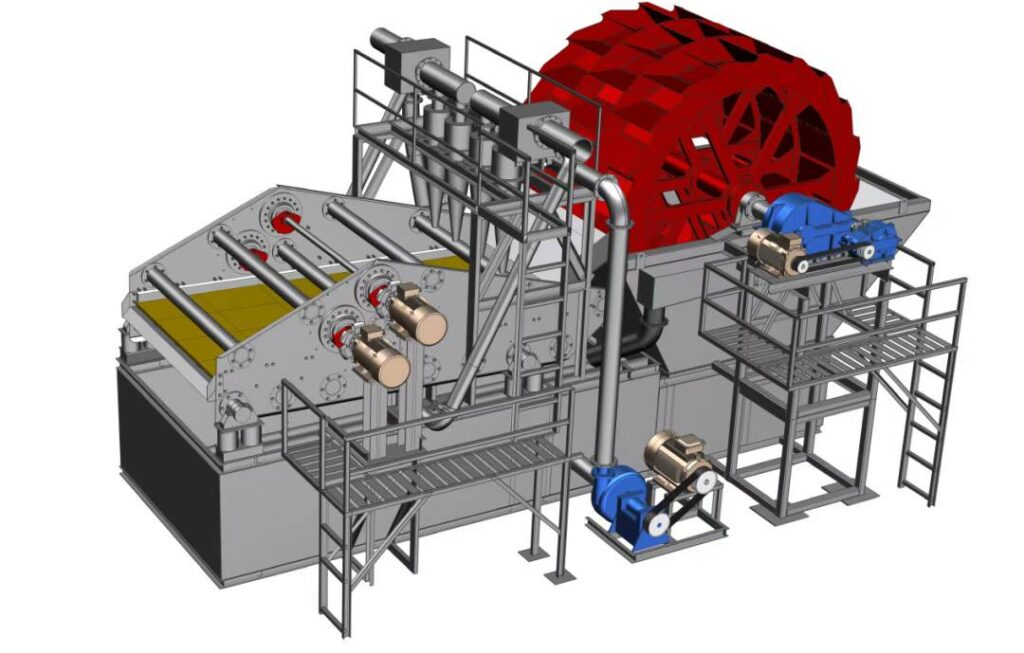

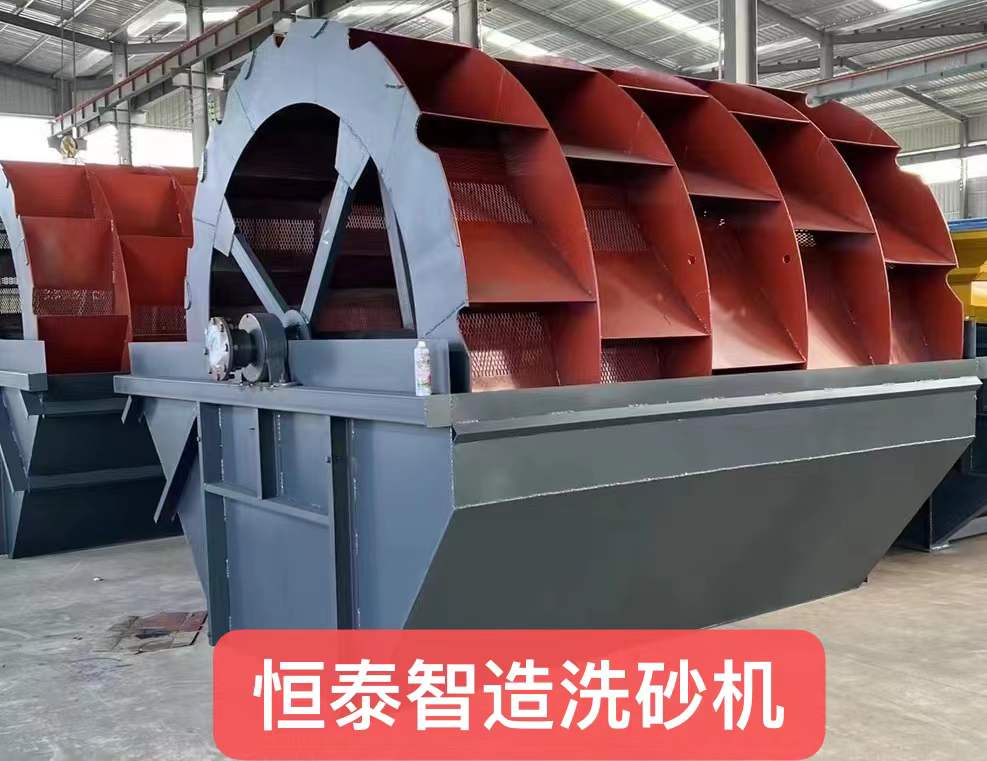

- Wheel Bucket Sand Washer – A modern water washing device that can clean both sand and gravel. Features high market demand due to its versatility.

- Vibrating Stone Washer – Cleans aggregates through vibration and water spraying, ideal for fine particle cleaning.

- Bucket Excavator Washer – Uses mechanical scooping combined with water spraying for large stone cleaning.

- Cylinder Stone Washer – Similar to the trommel washer but designed for continuous large-scale washing.

Working Principles

- Wheel Bucket Sand Washer: Consists of a wheel bucket, frame, and transmission system. Sand lifted by the wheel bucket is cleaned in a washing tank and discharged via a conveyor.

- Spiral Sand Washer: Built with an inclined water tank forming a sedimentation basin. The spiral is driven by a motor through a gearbox, rotating in the water to clean, dewater, and classify materials.

Performance Features

- Handles materials within 0–30 mm, effectively removing dirt, dust, and impurities.

- Simple structure, easy maintenance, and high washing efficiency.

- Can achieve cleaning, dewatering, and classification in one machine.

- Suitable for both natural and manufactured sand.