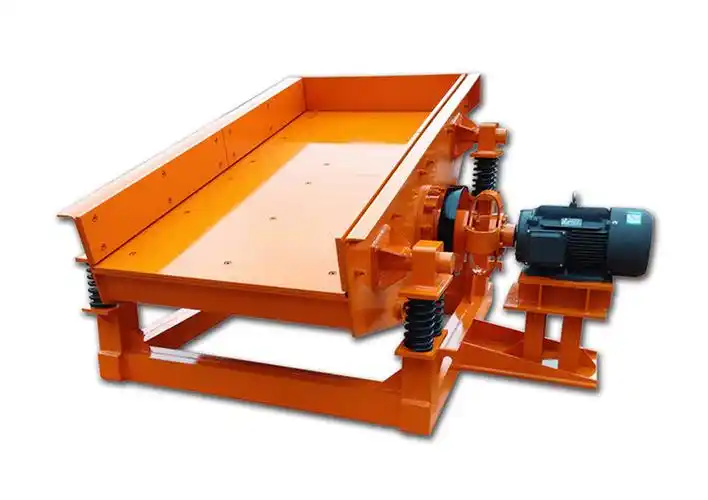

ZD -серия вибрирующий фидер: Reliable Feeding for Efficient Material Handling

The ZD Series Vibrating Feeder is a robust and efficient feeding solution designed for consistent material flow in crushing, скрининг, and bulk handling systems. Engineered for continuous operation under harsh industrial conditions, the ZD Series Vibrating Feeder ensures uniform feed rates and stable material supply to downstream equipment, playing a vital role in maximizing overall system efficiency.

1. What Is the ZD Series Vibrating Feeder?

The ZD Series Vibrating Feeder is an inertia-driven vibrating feeder that uses dual motors to generate linear vibration, ensuring even and controlled material discharge. It is widely used to transport bulk materials from storage bins to crushers, screens, or conveyors in mining, quarrying, metallurgy, and construction industries.

2. Key Features of ZD Series Vibrating Feeder

- Stable Feeding Performance

Uniform feeding reduces surge loading on crushers and screens, improving longevity and efficiency. - Dual Motor Drive System

The balanced dual-motor structure creates stable linear vibration for smooth material flow. - Durable Structure

High-strength welded steel body and wear-resistant liners ensure long-term reliability under heavy-duty conditions. - Adjustable Feeding Rate

Vibration amplitude and frequency can be adjusted to match specific material characteristics and output requirements. - Low Maintenance Design

Minimal moving parts mean fewer wear points and reduced downtime.

3. Working Principle

The ZD Series Vibrating Feeder operates by generating a linear vibratory motion through twin motors. This motion propels the material along the feeder trough, allowing for even and controlled discharge. By adjusting the motor angle or frequency, operators can control the feed volume according to the needs of the next processing stage.

4. Compatible Equipment

The ZD Series Vibrating Feeder integrates seamlessly with a wide range of processing equipment to form efficient production lines:

- Jaw Crusher / Cone Crusher / Impact Crusher – Ideal for feeding raw material into primary or secondary crushers.

- Вибрирующие экраны (e.g., YK Series) – Pre-screens materials before classification.

- Ленточные конвейеры – Transfers material downstream after uniform feeding.

- Sand Washing and Dewatering Equipment – Feeds material into wet processing systems.

- Hoppers and Storage Silos – Acts as an intermediate unit for regulated material discharge.

5. Application Industries

The ZD Series Vibrating Feeder is used across multiple industries, including:

- Mining and mineral processing

- Aggregates and construction materials

- Cement and concrete batching

- Coal and power generation

- Chemical and metallurgy industries

6. Real-World Use Case

In a typical stone crushing plant, the ZD -серия вибрирующий фидер is installed at the head of the line, feeding raw material into a jaw crusher. By ensuring continuous and stable material flow, it prevents clogging, reduces manual intervention, and significantly improves plant throughput.

7. Why Choose ZD Series Vibrating Feeder?

- Proven stability under high-load conditions

- Easy integration with modern automation systems

- Customizable trough sizes and motor configurations

- Long lifespan and low operating costs

- Ideal for both dry and slightly wet materials

Связаться с нами

To explore more about the ZD Series Vibrating Feeder and how it fits into your production line, visit our official website:

👉 https://slminingmachinery.com/

Our engineers can assist with system design, equipment selection, and on-site setup to ensure optimal feeding performance and operational efficiency.