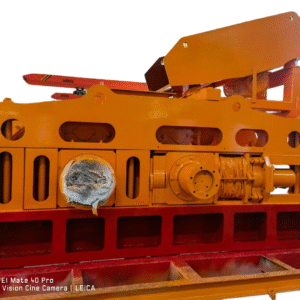

Double Roller Sand Making Machine — Precision Crushing for Diverse Materials

Double Roller Sand Making Machine Product Overview

The Двойной валичный песок, also known as the twin roll crusher, is a highly efficient medium and fine crushing solution designed for processing materials with medium hardness or below.

Widely used in sand production, mineral processing, cement manufacturing, and metallurgy, this equipment offers high capacity, adjustable output size, and consistent particle shape.

Its core structure consists of rollers, transmission system, and a pressure-adjustment mechanism. Through counter-rotating rollers, the machine applies strong compressive force to break materials into the desired size.

Equipped with hydraulic CNC technology, it enables precise discharge adjustment (0–5 mm adjustable) and comes with an intelligent control system and safety covers. It can process over 200 materials, including river pebbles, quartz stone, and even coal gangue.

Double Roller Sand Making Machine Working Principle

When material enters the crushing chamber, it is gripped by the rotating roller surfaces and forced into the gap between the rollers.

Here, the material undergoes compression and shearing forces, causing it to fracture.

-

Small particles pass through the roller gap and are discharged below.

-

Oversized particles remain for further crushing until they reach the required size.

The drive system uses dual motors connected via V-belts or gear reducers to ensure smooth operation.

Some models feature rubber side guards and filter bottom covers, effectively preventing sand leakage and reducing over-crushing rates.

Double Roller Sand Making Machine Applications

The double roller sand making machine is suitable for:

-

Mining and mineral processing – fine crushing of ores and minerals

-

Cement plants – producing high-quality cement aggregate

-

Refractory materials – crushing steel sand and ceramic raw materials

-

Chemical industry – reducing material size for further processing

-

Coal preparation plants – crushing raw coal and coal gangue

Double Roller Sand Making Machine Key Features

-

Precise output size control – Hydraulic CNC adjustment from 0–5 mm.

-

High versatility – Processes over 200 types of materials, from quartz to coal.

-

Stable performance – Robust roller design with wear-resistant surfaces.

-

Low maintenance – Dry grease lubrication system for longer bearing life.

-

Customizable drive system – Belt or gear reducer options.

Double Roller Sand Making Machine Technical Specifications

| Model | Max Feed Size (mm) | Output Size (mm) | Capacity (t/h) | Motor Power (kW) | Weight (kg) |

|---|---|---|---|---|---|

| 2PG-400×250 | ≤25 | 1–8 | 5–10 | 11 | 1500 |

| 2PG-400×500 | ≤30 | 1–15 | 10–20 | 22 | 2600 |

| 2PG-610×400 | ≤40 | 1–20 | 13–35 | 30 | 4500 |

| 2PG-750×500 | ≤40 | 2–20 | 15–40 | 37 | 12250 |

| 2PG-900×500 | ≤40 | 3–40 | 20–50 | 44 | 14000 |

Reviews

There are no reviews yet.