See How the Hammer Crusher Improves Efficiency in Soft Rock Crushing

In the mining and aggregate industries, hammer crushers have become a go-to solution for processing soft to medium-hard materials. Known for their simplicity, efficiency, and cost-effectiveness, hammer crushers offer a unique advantage in soft rock applications such as limestone, coal, gypsum, shale, and bauxite.

In this article, we’ll explore how hammer crushers work, their advantages in soft rock crushing, and how they can help you reduce operational costs while boosting productivity.

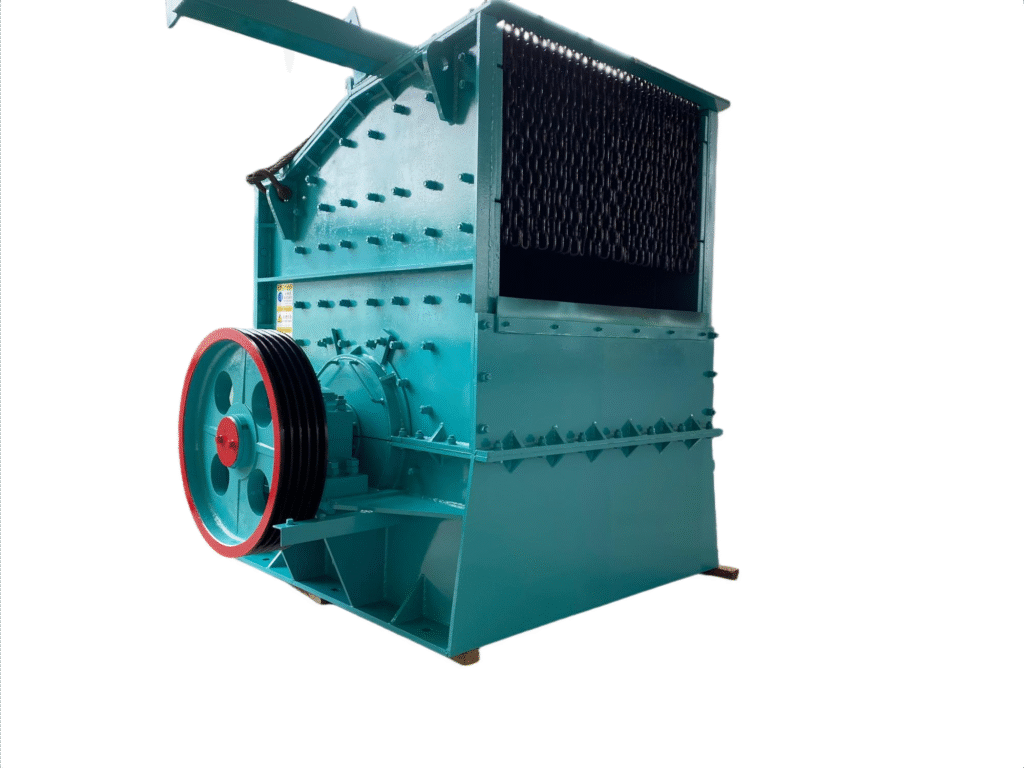

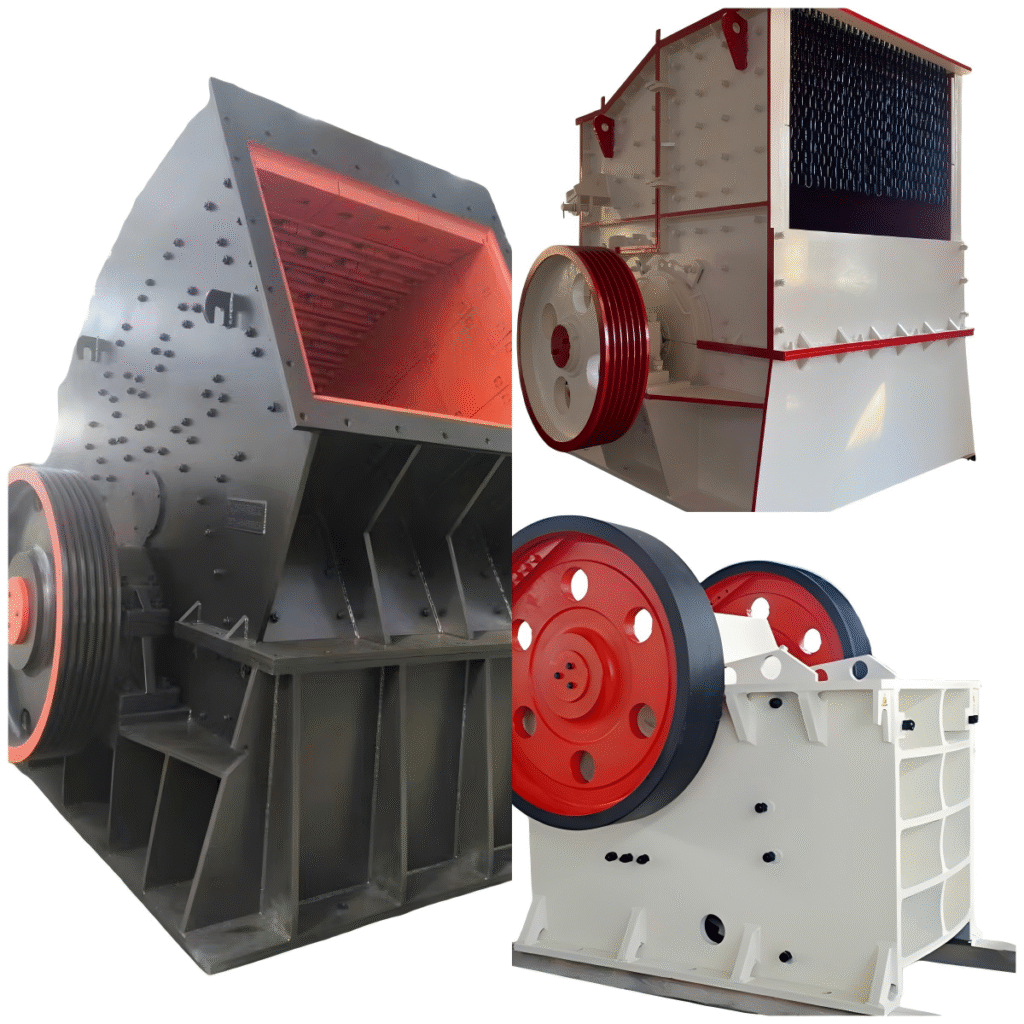

🔧 What Is a Hammer Crusher?

A hammer crusher is a crushing machine that uses high-speed rotating hammers to impact and break materials into smaller particles. Unlike jaw or impact crushers that rely on compression or secondary collisions, the hammer crusher delivers direct hits — making it ideal for brittle, less abrasive materials.

✅ Key Advantages of Hammer Crushers for Soft Rock

1. One-Time Crushing — Simplified Process

Hammer crushers are capable of one-stage crushing, which means large feed materials can be reduced to the desired size in a single pass. This simplifies the overall crushing process and eliminates the need for secondary crushers.

💡 Suitable for soft rocks like limestone and clay with moisture content under 15%.

2. High Crushing Efficiency

Thanks to its high-speed rotor design and direct impact mechanism, a hammer crusher offers faster throughput and reduced energy consumption compared to traditional systems.

3. Lower Operational Costs

- Fewer machines required on-site

- Simpler maintenance and easy replacement of wear parts

- Compact footprint, saving on infrastructure investment

4. Moisture Tolerance

Some hammer crusher models are specially designed to handle slightly wet materials, making them useful in environments where pre-drying is not feasible.

🛠️ Typical Application Scenarios

Hammer crushers are commonly used in the following industries and materials:

| Industry | Material Examples |

|---|---|

| Cement Plants | Limestone, marl, clay |

| Coal Processing | Bituminous coal, lignite |

| Chemical Industry | Phosphates, salt, gypsum |

| Building Materials | Brick shale, lightweight aggregates |

| Metallurgy | Bauxite, aluminum ore |

🆚 Hammer Crusher vs. Other Crushers

| Feature | Hammer Crusher | Jaw Crusher | Impact Crusher |

|---|---|---|---|

| Ideal for Soft Rock | ✅ Yes | ⚠️ Limited | ✅ Yes |

| One-Time Crushing | ✅ Yes | ❌ No | ⚠️ Limited |

| Operating Cost | ✅ Low | ⚠️ Medium | ⚠️ Medium |

| Moisture Tolerance | ✅ Good | ❌ Poor | ⚠️ Moderate |

| Maintenance Simplicity | ✅ Easy | ⚠️ Moderate | ⚠️ Moderate |

📈 How Hammer Crushers Improve Overall Efficiency

Using hammer crushers in soft rock crushing applications leads to:

- 30–50% shorter production cycles

- Up to 25% energy savings

- Reduced maintenance downtimes

- Improved final product consistency

📩 Ready to Upgrade Your Soft Rock Crushing System?

If your plant handles materials like limestone, coal, or clay, a hammer crusher could be the most cost-effective and high-efficiency solution for your operation.

👉 Contact us now to get technical support, pricing, and a customized crushing solution tailored to your material needs.

Продукция – Премиальные решения для сокрушительных решений для глобальной добычи & Строительство