-

Maximum Feeding Size: 100 mm

-

Discharge Adjustment Range: 8–25 mm

-

Capacity: 42–135 t/h

-

Motor Power: 110 kW

PYZ Type (Fine Crushing Type)

-

Produces finer discharge particle size

-

Commonly used for secondary fine crushing after medium crushing

-

Suitable for applications requiring high product particle size standards

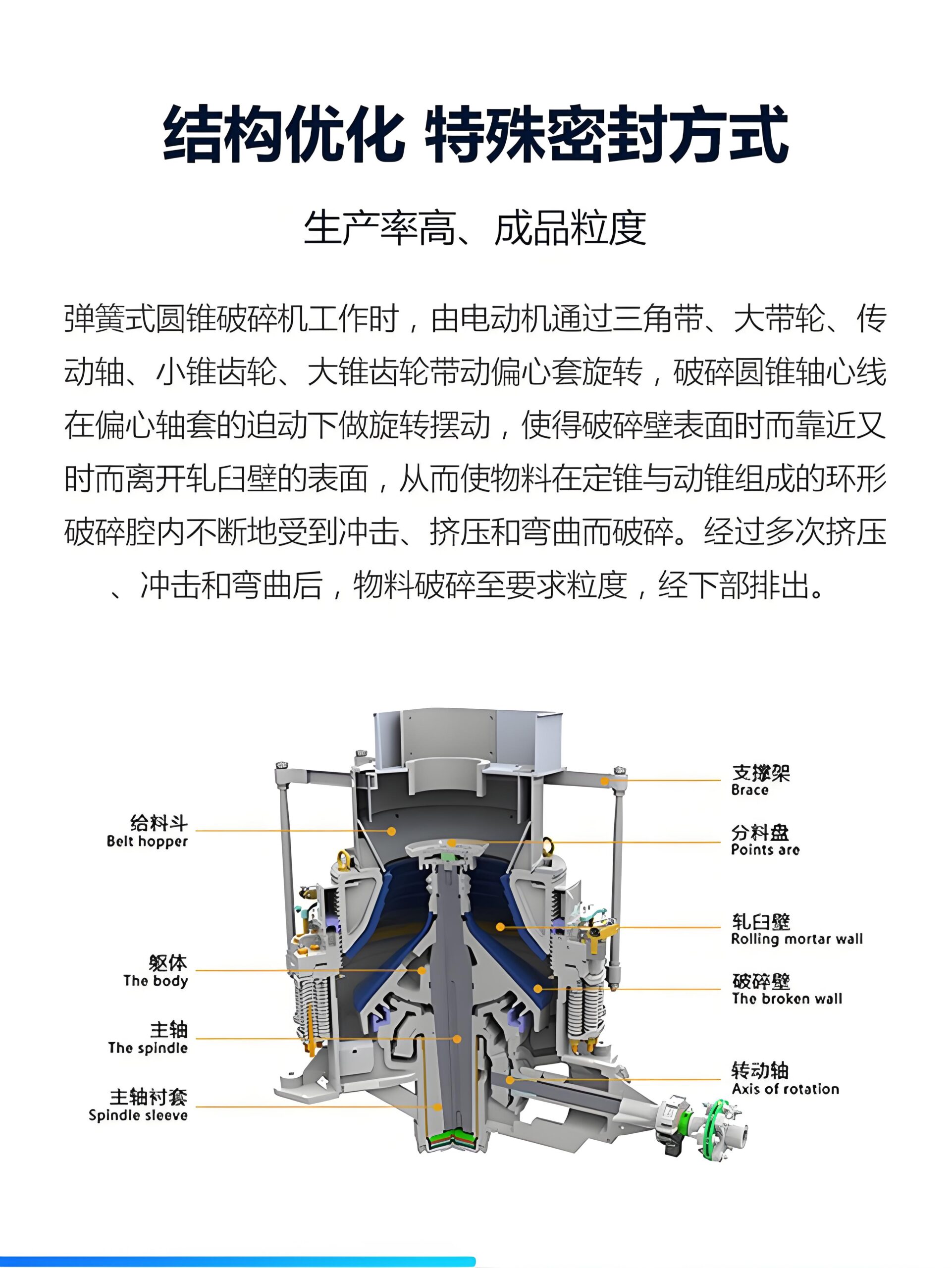

Working Principle

The cone crusher mainly consists of a frame, transmission device, eccentric sleeve, moving cone, and fixed cone.

The motor drives the transmission shaft to rotate via a belt or coupling, causing the eccentric sleeve to rotate around the main shaft. This movement makes the crushing wall perform a swinging motion. Materials enter the crushing chamber from the top and are crushed by the squeezing and bending action between the moving cone and the fixed cone, then discharged from the bottom.

Performance Features

-

Simple structure, easy to operate and maintain

-

Large crushing ratio with uniform product particle size

-

Safe and reliable lubrication system with long service life

Reviews

There are no reviews yet.