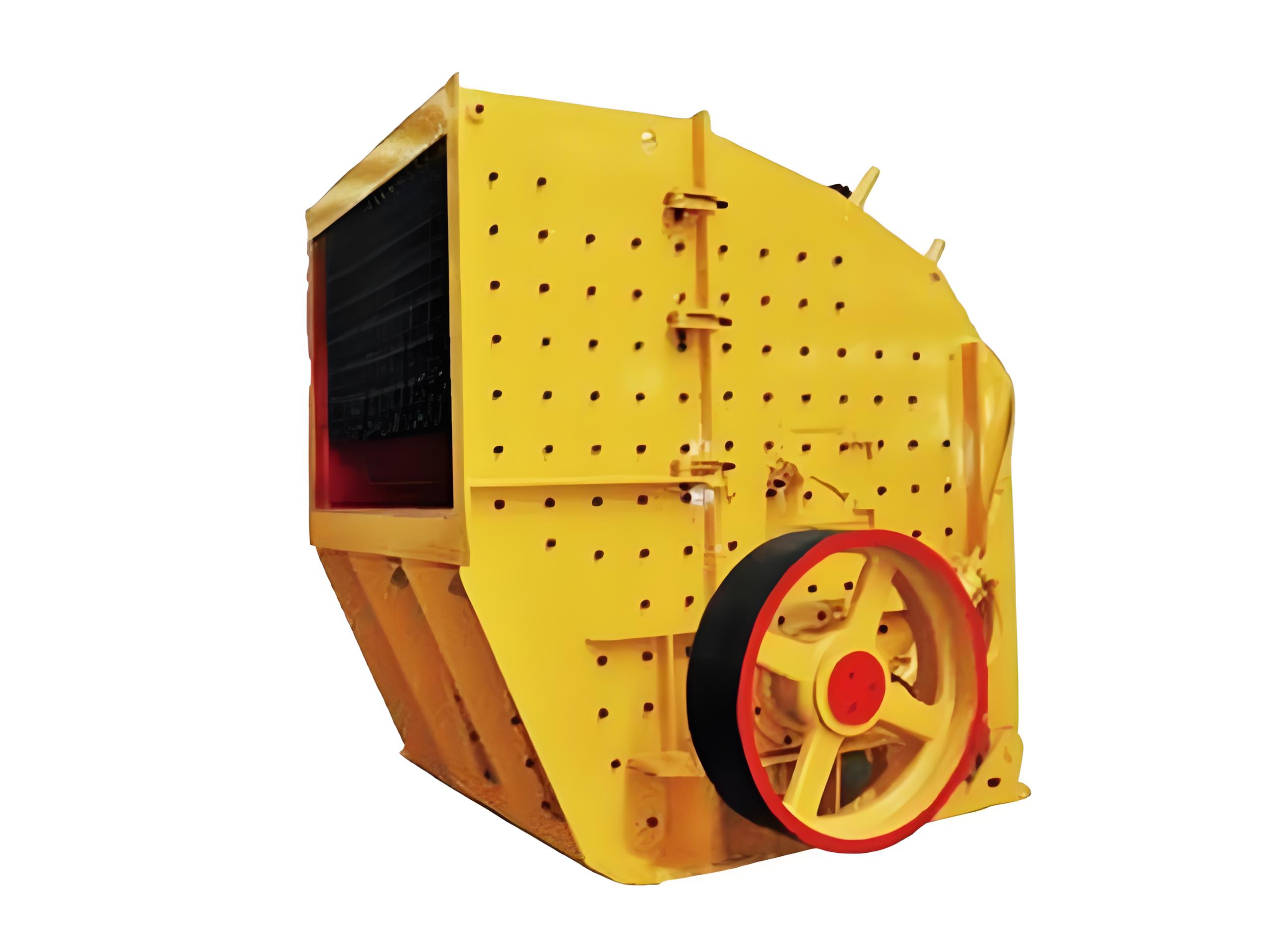

PFW1210Ⅱ European Impact Crusher

Model: PFW1210Ⅱ

Rotor Size: Ø1150 × 960 mm

Feed Opening Size: 1100 × 1030 mm

Maximum Feed Size: 400 mm

Processing Capacity: 90–160 t/h

Motor Power: 90–110 kW

Overall Dimensions (L × W × H): 2400 × 1870 × 2550 mm

Product Introduction

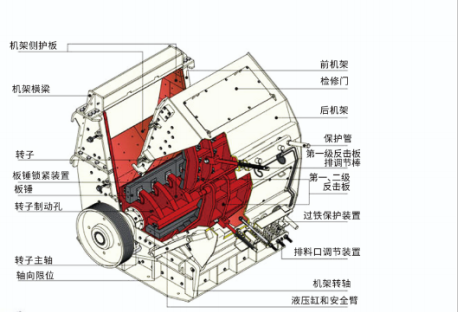

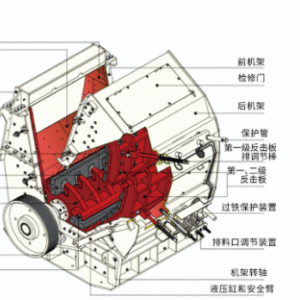

The PFW Series European Impact Crusher is the latest generation product that adopts the most advanced international crushing technology. It represents world-class manufacturing craftsmanship and uses the highest-grade materials. The heavy-duty rotor design, combined with strict testing measures, ensures a high-quality rotor. The rotor is the “heart” of the crusher and the most rigorously inspected component of an impact crusher, playing a crucial role during operation. Therefore, the company has developed and manufactured a robust heavy-duty rotor to achieve higher rotational inertia.

With high wear-resistant materials and an optimized crushing chamber, the crusher delivers outstanding performance. The bearing housing adopts an integrated cast steel structure, and the unique hammer locking system significantly improves hammer reliability. The improved adjustment mechanism reduces downtime and maintenance efforts. The built-in top-opening device allows for quick replacement of wear parts such as hammers. Larger bearing specifications offer higher load-bearing capacity. Rotor analysis ensures stability and reliability.

Performance Features

High-chromium blow bars and unique impact plates ensure long service life.

Stable rotor operation with a keyless connection to the main shaft.

Final products are cubic in shape, free of tension and cracks, with excellent particle quality.

Adjustable discharge size simplifies the crushing process.

Easy maintenance and simple, reliable operation.

Working Principle

The PFW Series European Impact Crusher operates based on the principle of impact energy. When the material enters the crushing chamber, it is first struck by the high-speed rotating blow bars on the rotor, which throws the material against the impact plates for secondary crushing. The material then rebounds from the impact plates back into the path of the rotating blow bars for repeated crushing until it reaches the desired size and is discharged through the outlet.

Equipped with multiple crushing chambers, the crusher performs staged crushing to improve efficiency. The gap between the impact rack and rotor can be adjusted to control the output size. The hydraulic opening system and automatic adjustment mechanism simplify maintenance and minimize downtime.

Reviews

There are no reviews yet.