Jaw Crusher Overview – PE400×600

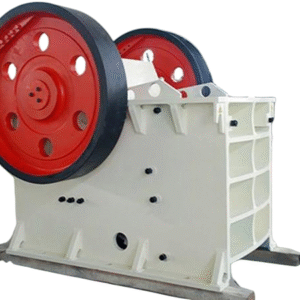

The jaw crusher is a widely used general-purpose device in China’s crushing industry, and is indispensable in sectors such as mining, aggregates, and building materials. As a medium-sized model in its product series, the PE400×600 jaw crusher is flexible and versatile. It can be specifically configured to meet various operational requirements, making it highly favored by users.

🦾 PE400×600 Jaw Crusher — Technical Specification Sheet

Feed Opening Size: 400 × 600 mm

Max. Feeding Size: ≤ 350 mm

Discharge Opening Size: 40–100 mm

Capacity: 16–65 t/h

Motor Power: 30 kW

Machine Weight: 7 tons

Color: Customizable

Overall Dimensions:

-

Option 1: 1700 × 1732 × 1653 mm

-

Option 2: 1623 × 1736 × 1615 mm

🔨 Typical Materials for Crushing

The PE400×600 jaw crusher is ideal for crushing medium-soft to medium-hard materials, such as:

-

Limestone

-

Shale

-

Dolomite

-

Small river pebbles

Key Features

-

Low noise and minimal dust emission.

-

High crushing ratio with uniform product size.

-

Simple structure, reliable operation, and low operating cost.

-

Safe and reliable lubrication system; parts are easy to replace, and maintenance is simple.

-

Deep crushing chamber with no dead zone, improving feeding capacity and output.

-

Energy-saving: saves 15%–30% energy per machine, with system-level energy savings exceeding 50%.

-

Wide adjustment range of discharge opening to meet various user requirements.

-

Shim-type discharge adjustment device is reliable and easy to use, increasing equipment flexibility.

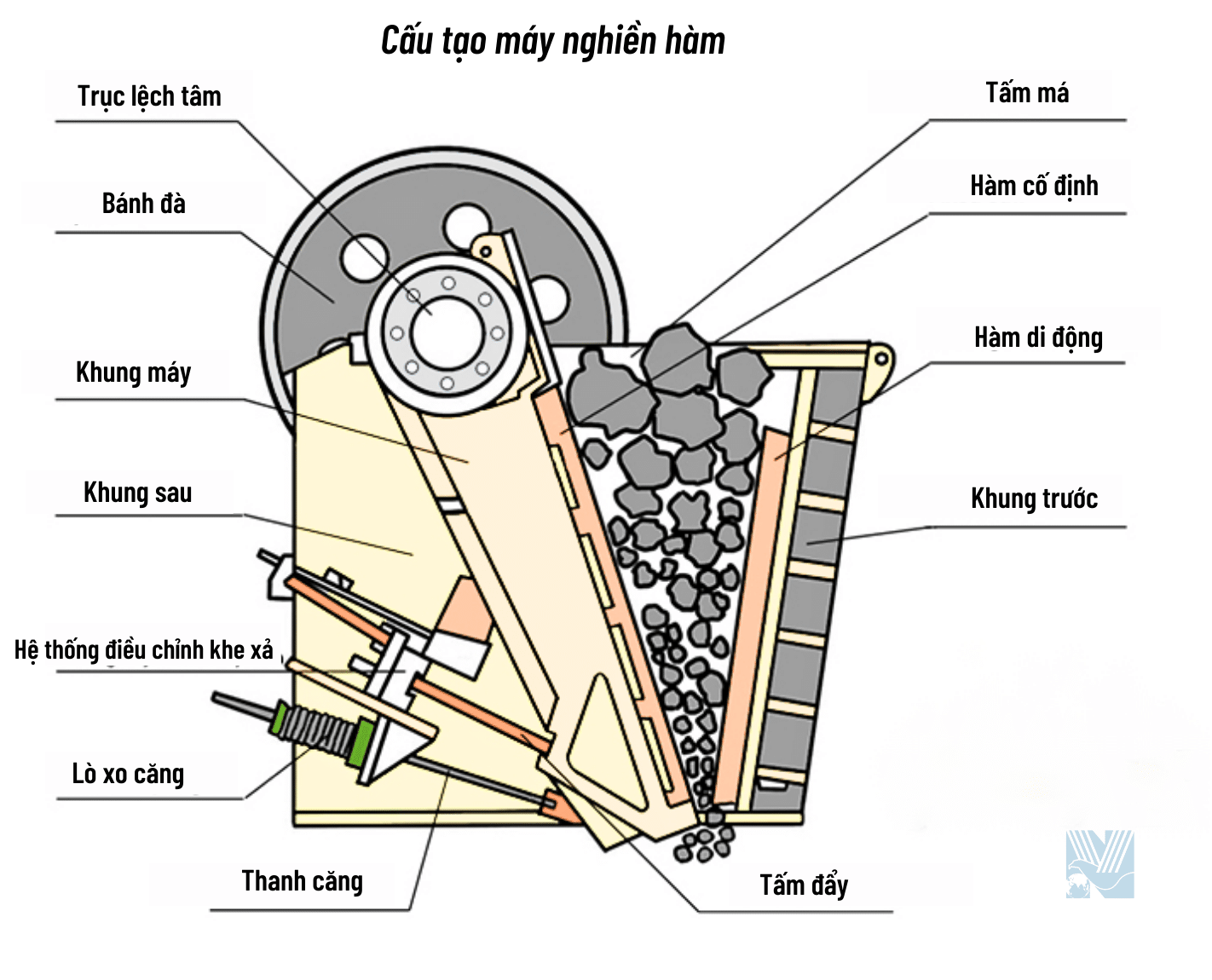

Main Components

-

Frame:

A rigid box-shaped structure with openings at both ends, the frame supports the eccentric shaft and withstands the reactive forces of the crushed materials. It must have sufficient strength and rigidity. Typically, it is made of cast steel; smaller machines may use high-quality cast iron instead. For large machines, the frame is often cast in sections and bolted together due to the complexity of the casting process. For homemade small crushers, thick steel plates can be used for welding, though this results in lower rigidity. -

Jaw Plates and Side Guard Plates:

The fixed and movable jaws each consist of a jaw base and jaw plate. The jaw plate is the working part, bolted and wedged onto the base. The fixed jaw base is part of the front frame, while the movable jaw base is suspended and must be strong enough to handle crushing forces, typically made of cast steel or cast iron. -

Transmission Components:

The eccentric shaft is the main shaft of the crusher and bears significant bending and torsional stress. It’s made of high-carbon steel, with precision machining and heat treatment. The bearing surfaces are typically cast with Babbitt alloy. One end of the shaft carries the pulley, and the other end supports the flywheel. -

Adjustment Device:

Common adjustment mechanisms include wedge-type, shim-type, and hydraulic types. The wedge-type consists of two wedges: the front wedge can move forward or backward to push the toggle plate, while the rear wedge adjusts vertically. The inclined surfaces of both wedges are tightly matched. A screw moves the rear wedge up or down to adjust the discharge opening. In small crushers, discharge adjustment is done by adding or removing shims between the toggle seat and the frame. -

Flywheel:

The flywheel stores energy during the idle stroke of the movable jaw and releases it during crushing to ensure smooth operation. It is usually made of cast iron or cast steel. For smaller machines, the flywheel is often an integral part of the pulley. During manufacturing and installation, flywheel balance is crucial for stable performance. -

Lubrication Device:

Bearings on the eccentric shaft are typically lubricated via a centralized circulation system. The contact surfaces of the shaft and toggle plate are manually greased. Because the swing angle of the movable jaw is small, shaft lubrication is challenging; therefore, axial oil grooves and a circumferential groove are machined into the bearing for connection, allowing forced lubrication with thick grease using an oil pump.

Reviews

There are no reviews yet.