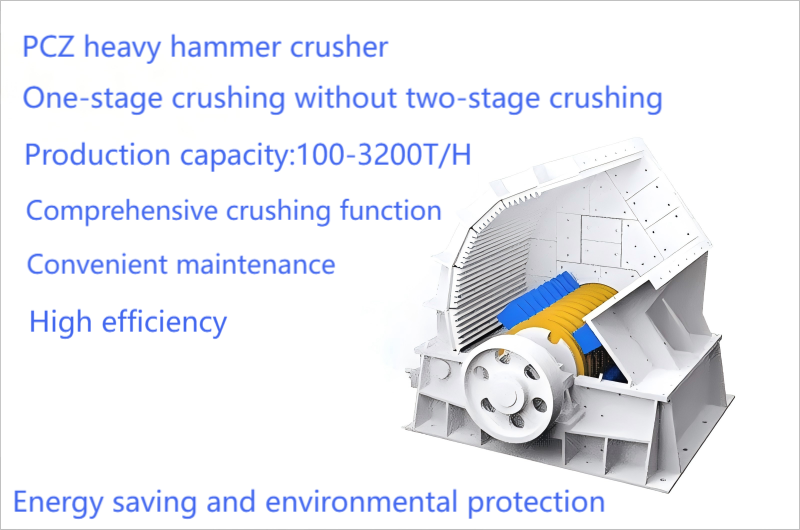

📌 Model: PCZ Heavy Hammer Crusher 1816

-

Max. Feeding Size: 900 mm

-

Output Size Range: 0–100 mm

-

Production Capacity: 360–460 t/h

-

Motor Power: 280–315 kW

Heavy Hammer Crusher⚙️ Working Principle

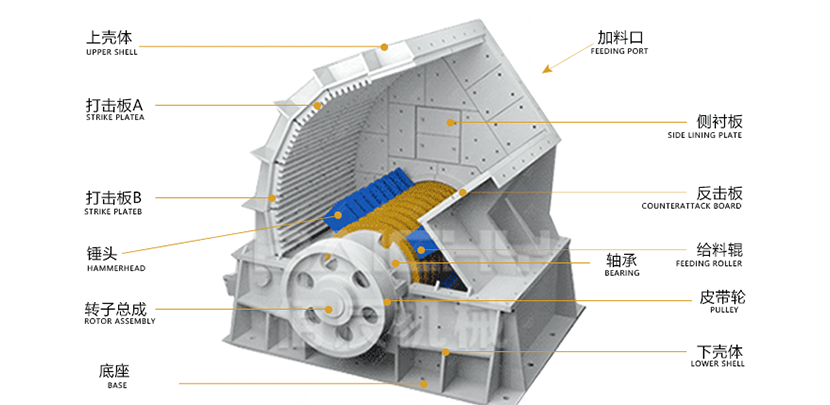

Driven by an electric motor, the rotor disc equipped with hammers rotates at high speed. Once material enters the crushing chamber, it is struck by the hammers and propelled toward impact plates, where it experiences high-speed collisions. Additional friction and impact between particles further break the material down. Particles that meet the required size are discharged, while oversized materials are recirculated for additional crushing until they reach the desired size.

Heavy Hammer Crusher⭐ Performance Features

-

Simple structure with stable operation

-

Large feed size and high crushing ratio with uniform output

-

Capable of one-time crushing and forming final product

-

Wear-resistant components and low maintenance requirements

-

Large single-machine capacity: 120–2000 t/h

-

360° hammer rotation helps reduce hammer breakage incidents

-

Efficient one-step crushing process

Heavy Hammer Crusher🧱 Material Suitability

The PCZ Heavy Hammer Crusher is best suited for medium-hard and brittle materials, typically with compressive strength ≤150–200 MPa.

Heavy Hammer Crusher✅ Primary Applicable Stone Types

-

Limestone

-

Typically <150 MPa; ideal for heavy hammer crushing

-

-

Bluestone

-

Medium hardness, ≤200 MPa; high crushing efficiency

-

-

Coal Gangue

-

Highly brittle, low abrasiveness; good crushing results

-

-

River Pebbles / Cobbles

-

Suitable if compressive strength ≤200 MPa

-

⚠️ Conditionally Applicable Materials (must meet strength limits)

-

Dolomite (≤200 MPa)

-

Sandstone (medium hardness)

-

Marble (≤200 MPa)

-

Low-abrasion Basalt (strength verification required)

❗ Key Usage Limitations

-

Compressive Strength Limit: ≤150–200 MPa (varies by model)

-

Material Properties: Only applicable to brittle, medium-hard, and low-abrasion materials

-

High-hardness materials (e.g., granite, iron ore): must be carefully evaluated; cone crushers may be preferred

-

Calcium Content: Some models require Ca content ≥40% in the material

💡 Equipment Advantages

The PCZ Heavy Hammer Crusher allows one-step crushing and shaping, especially suitable for projects with capacity requirements under 600 t/h. It removes the need for secondary crushing stages, reducing investment and operating costs by up to 40%. With a large feed size capability (up to 1200 mm), it fits mid-scale crushing applications in mining, construction, and chemical industries.

Note: Final equipment selection should be based on detailed material characteristics (e.g., compressive strength, abrasion index) to ensure compatibility with the selected model.

Reviews

There are no reviews yet.