High-Performance PE Jaw Crusher: Maximizing Coverage and Efficiency

The PE Jaw Crusher is a widely used primary crushing machine in mining, construction, and aggregate production. Known for its reliability, high crushing ratio, and simple structure, it has become an essential piece of equipment in various industries. This powerful machine is especially effective in processing hard materials such as granite, basalt, and iron ore, making it a preferred choice for both large-scale operations and smaller quarrying projects.

What is a PE Jaw Crusher?

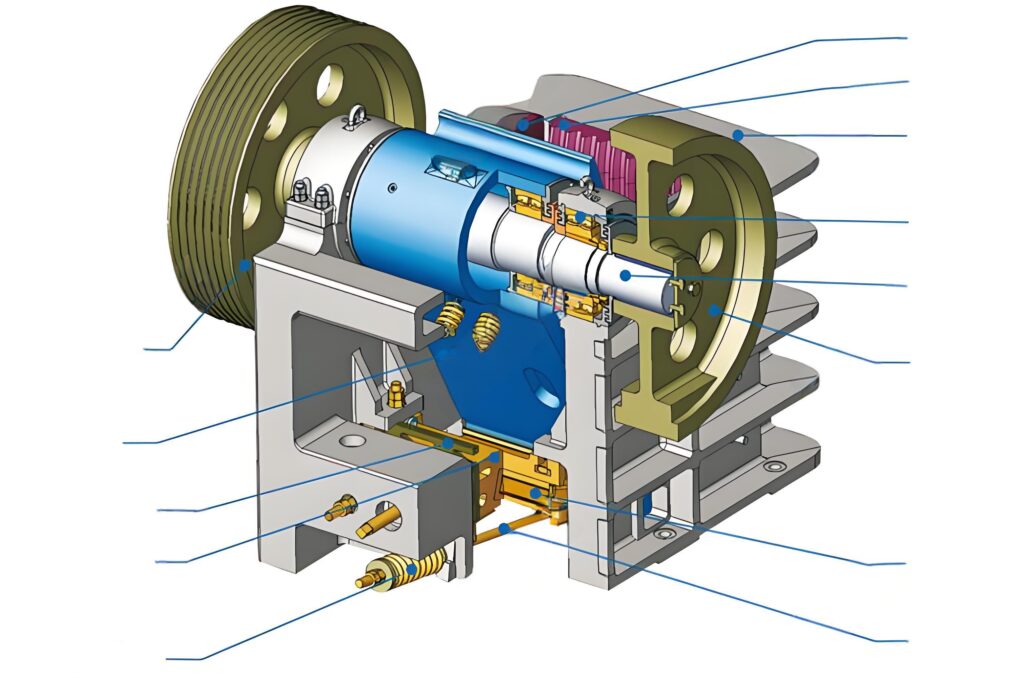

A jaw crusher works by using compressive force to break down materials into smaller, more manageable pieces. The PE (Primary Energy-saving) series jaw crusher is designed for coarse crushing applications, with the feed size typically ranging from 125mm to 1200mm. It consists of two jaw plates — a fixed jaw and a movable jaw — that together crush the material through compressive action.

Key Features and Benefits

- High Crushing Efficiency: The deep crushing cavity and optimized design allow for greater throughput and crushing performance.

- Durability and Strength: Made from high-manganese steel, the jaw plates are wear-resistant and long-lasting, reducing maintenance frequency and costs.

- Easy Maintenance: A simple structure ensures easy access to parts and less downtime during servicing.

- Wide Range of Applications: Suitable for mining, metallurgy, building materials, highway, railway, and chemical industries.

Industry Coverage Rate

The PE jaw crusher has achieved a coverage rate of 65% in the primary crushing equipment market due to its adaptability, energy efficiency, and performance consistency. This widespread use is a testament to its reliability and capability in various challenging environments. It has become the go-to equipment for many mining and construction projects, especially in developing regions where infrastructure demands are rising rapidly.

Why Choose the PE Jaw Crusher?

- High Return on Investment: With low operating costs and high output, it offers excellent ROI.

- Versatility: Handles a wide range of materials and is compatible with different production lines.

- Environmental Compliance: Engineered for reduced dust and noise emissions, promoting a greener working environment.

Conclusion

For those looking for a durable, efficient, and cost-effective solution in primary crushing, the PE Jaw Crusher stands out as a top choice. With a market coverage rate of 65%, it has proven itself across numerous industries and applications.

Interested in learning more or getting a quote?

Contact us today: https://slminingmachinery.com/contact-2/