Mobile Crushing and Screening Equipment: Excellent Crushing Performance and Versatile Applications

With the development of the construction, mining, and recycling industries, mobile crushing and screening equipment has become widely used due to its high efficiency, flexibility, and environmental benefits. Mobile crushing and screening equipment integrates both crushing and screening functions, making it suitable for on-site operations without the need for complex installation or debugging, significantly improving work efficiency. Whether for stone production or construction waste recycling, mobile crushing and screening equipment delivers excellent crushing performance and high-quality screening results.

This article will provide a detailed overview of the available equipment that can be mounted on mobile crushing and screening units, its advantages, the types of stones it can crush, and its applications, helping you better understand how this equipment provides efficient solutions in real-world operations.

Available Equipment for Mobile Crushing and Screening Units

One of the key advantages of mobile crushing and screening equipment is its high adaptability, allowing it to carry a variety of equipment to meet different production needs. Common equipment mounted on mobile units includes:

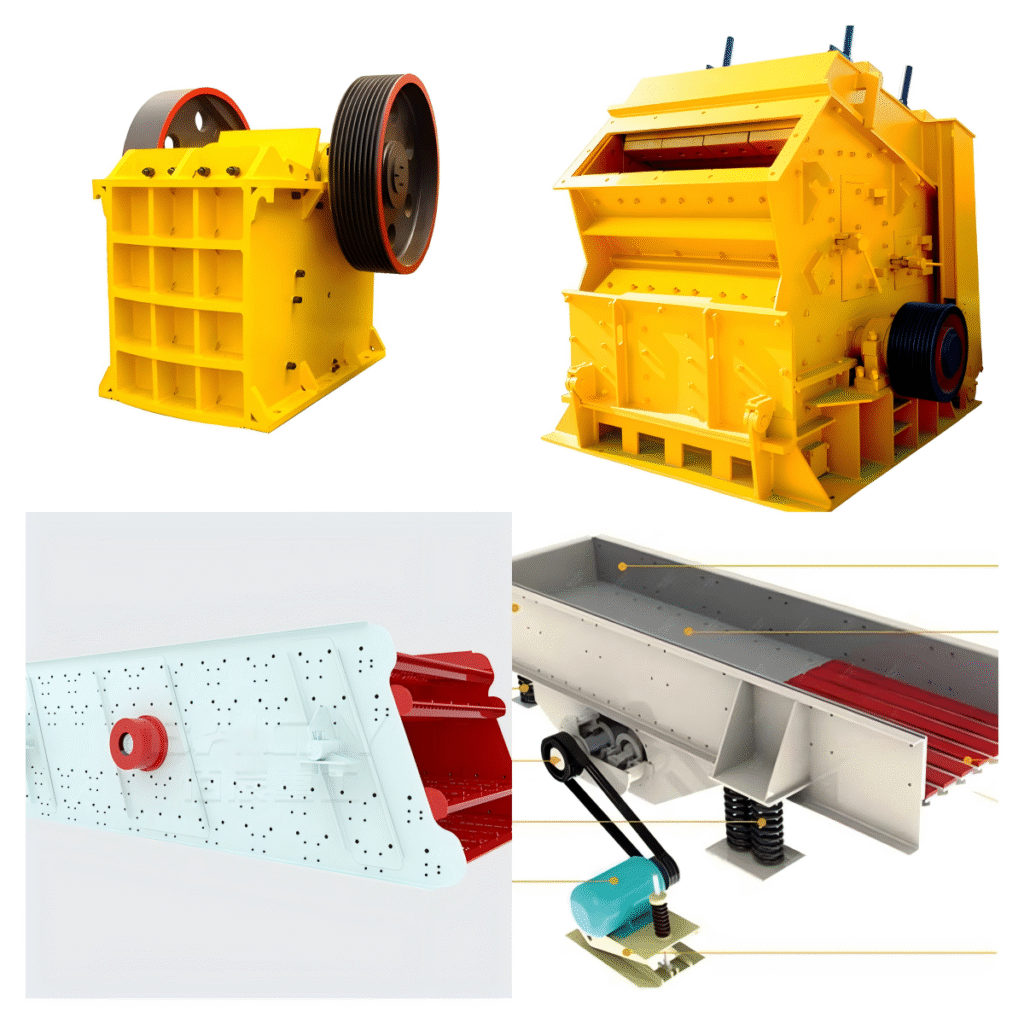

- Jaw Crusher

As the main crushing unit in mobile crushing and screening equipment, the jaw crusher is suitable for primary crushing of medium-hard materials, offering high crushing efficiency. - Impact Crusher

The impact crusher efficiently handles soft to medium-hard materials, commonly used for fine crushing or secondary crushing, making it ideal for producing high-quality sand and aggregate. - Cone Crusher

The cone crusher is ideal for processing harder materials such as limestone, granite, and other hard rocks, commonly used in the secondary crushing stage. - Screening Machine

The screening machine is used to classify the crushed materials, dividing them into different grades based on particle size to meet specific production requirements. - Conveyor Belt

The conveyor belt works in tandem with the crushing and screening system to efficiently transport crushed materials, reducing labor costs.

Advantages of Mobile Crushing and Screening Equipment

- Flexibility and High Efficiency

Mobile crushing and screening equipment does not require complex installation and can be directly moved to the site for operation, greatly improving efficiency. Its high flexibility allows it to adapt quickly to different job sites, saving transportation costs. - Energy Efficiency and Environmental Benefits

The mobile crushing and screening units use advanced environmental technologies, such as low-noise designs and closed-circuit crushing systems, effectively reducing noise and dust pollution, and complying with modern environmental standards. - Multi-functional Integration

Mobile crushing and screening equipment integrates crushing, screening, transportation, and stacking functions into one system, reducing intermediate processes and improving overall work efficiency. - Lower Maintenance Costs

Due to its simple structure and easy operation, most mobile units are equipped with automatic monitoring systems to track the equipment’s performance, which helps reduce maintenance costs and downtime.

Types of Stones Mobile Crushing and Screening Equipment Can Process

Mobile crushing and screening equipment is suitable for processing various types of stone materials, including but not limited to the following:

- Limestone

Limestone is a common building material. Mobile crushing and screening units can efficiently process limestone and produce various-sized aggregates for construction, sand production, and cement industries. - Granite

Granite is a hard rock that mobile crushing and screening equipment can efficiently crush, making it ideal for producing high-quality aggregates for building and road construction. - River Pebbles

River pebbles are commonly used in highway and railway construction. Mobile crushing and screening equipment can efficiently crush river pebbles into desired sizes, producing high-quality aggregates. - Coal Gangue

In mining waste recycling, mobile crushing and screening units can process coal gangue, crushing it into the required specifications and reducing waste disposal costs. - Construction Waste

In construction waste recycling, mobile crushing and screening units can handle concrete, bricks, and other debris, recovering valuable aggregates for reuse.

Applications of Mobile Crushing and Screening Equipment

- Construction Industry

Mobile crushing and screening equipment is commonly used at construction sites to process waste materials and recycle them into usable aggregates for new construction projects, reducing transportation costs. - Mining Operations

In mining, mobile crushing and screening units are used for primary, secondary, and fine crushing on-site, improving production efficiency and reducing transportation costs. - Road and Railway Construction

Mobile crushing and screening units provide the necessary crushed stones and sand for road and railway projects, ensuring the quality of road surface materials. - Waste Recycling and Disposal

The equipment is also widely used in waste recycling, especially for processing urban waste and construction debris, providing a sustainable solution for waste management.

Frequently Asked Questions (FAQ)

1. What is the production capacity of mobile crushing and screening equipment?

The production capacity of mobile crushing and screening units typically depends on the type of equipment and the characteristics of the material being processed. Generally, a unit can produce several hundred to thousands of tons of material per day.

2. Is maintenance of mobile crushing and screening equipment frequent?

Maintenance of mobile crushing and screening equipment is relatively simple. Regular inspections, lubrication, and replacement of worn parts are required. The design of the equipment reduces the need for frequent downtime and maintenance.

3. Can the equipment configuration be customized?

Yes, the configuration of mobile crushing and screening equipment can be customized according to your specific production requirements and job site conditions.

4. How environmentally friendly is mobile crushing and screening equipment?

These units feature a closed design to minimize dust emissions and are equipped with low-noise technology, ensuring compliance with modern environmental standards.

Contact Us

If you have any questions about mobile crushing and screening equipment or need more information about equipment selection, configuration, and pricing, feel free to visit our website: S.L. Mining Machinery. Our professional team is ready to provide you with the most suitable solution.