1200TPH Limestone Production Line | Efficient & Economical Crushing Solution

1. Applications of Limestone

Limestone is one of the most versatile and abundant sedimentary rocks used in industrial and construction sectors. With a compressive strength around 150 MPa, it is classified as a soft rock, making it ideal for high-capacity crushing lines.

Common Applications Include:

- Cement Manufacturing: As the primary ingredient for clinker.

- Aggregate for Construction: Base material for roads, highways, and buildings.

- Desulfurization in Power Plants: Used in flue gas treatment.

- Soil Conditioner: Neutralizes acidic soils in agriculture.

- Glass and Chemical Industries: Raw material for soda ash and lime.

Its broad usability and ease of processing make limestone a cornerstone material in many infrastructure projects.

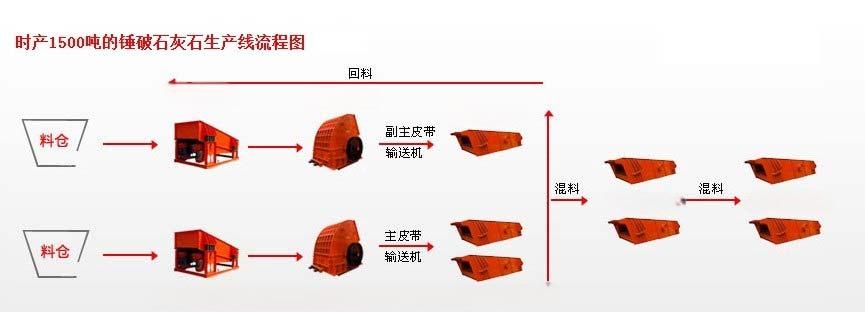

2. Limestone Production Line Process Flow (1200TPH)

This 1200 tons per hour (TPH) limestone crushing line is designed for high-efficiency, low operating cost, and consistent aggregate output. It adopts a two-stage closed-circuit crushing system based on the physical properties of limestone.

Process Overview:

- Primary Feeding:

- Raw limestone (<1200mm) blasted from the mountain is transported by dump trucks.

- A ZG-2050 Vibrating Feeder evenly distributes material into the first-stage crusher.

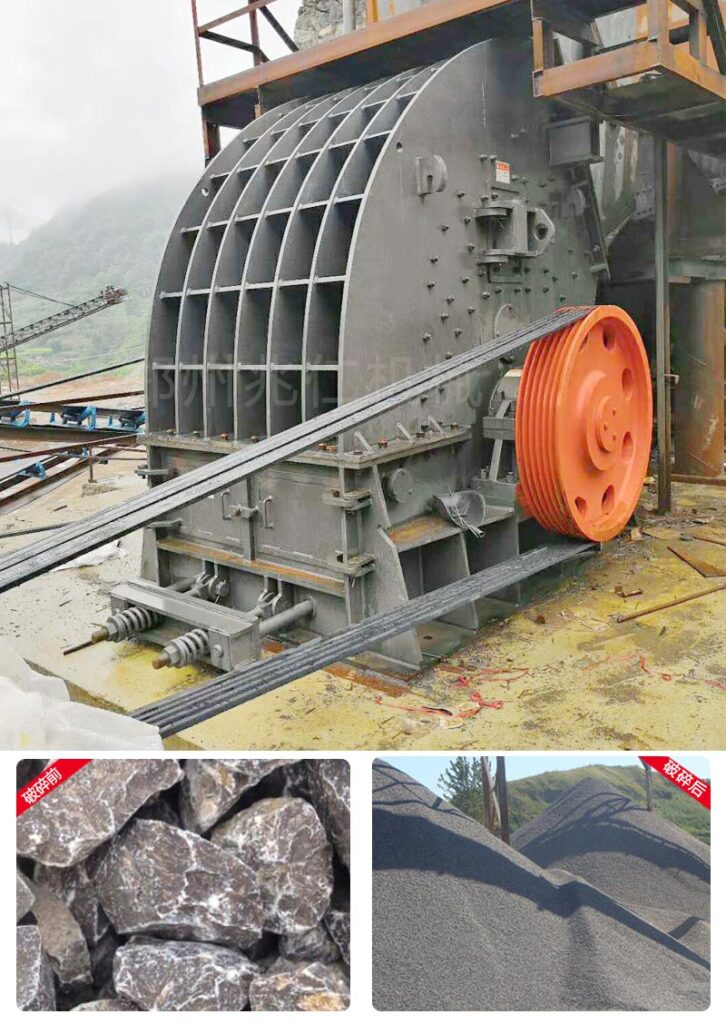

- Primary Crushing:

- The PCZ-1820 Heavy Hammer Crusher performs coarse crushing, reducing large rocks into smaller chunks.

- Secondary Crushing:

- Crushed materials are conveyed into the PC-1216 and PC-1220 Hammer Crushers for fine crushing and shaping.

- Screening & Recycling:

- Finished material is screened using 3 units of 3YKZ3070 and 2 units of 2YKZ3070 Circular Vibrating Screens.

- Oversized particles are returned to the secondary crushers for re-crushing via belt conveyors.

- Qualified materials are transported to the final stockpile by belt conveyors.

Crushing System Configuration:

| Equipment | Model | Quantity |

|---|---|---|

| Vibrating Feeder | ZG-2050 | 1 Unit |

| Heavy Hammer Crusher | PCZ-1820 | 1 Unit |

| Hammer Crusher | PC-1216 | 1 Unit |

| Hammer Crusher | PC-1220 | 1 Unit |

| Circular Vibrating Screen | 3YKZ3070 | 3 Units |

| Circular Vibrating Screen | 2YKZ3070 | 2 Units |

Why This Design Works:

Given limestone’s moderate strength and friability, the use of dual-stage heavy hammer crushers in a closed-loop system is an ideal solution. It minimizes investment, simplifies layout, and reduces operational costs while maximizing output efficiency.

3. Recommended Auxiliary Equipment

To ensure stable and continuous operation, the following supporting equipment is recommended:

- Belt Conveyors – For material transfer and closed-circuit return.

- Dust Collectors – To meet environmental compliance standards.

- Control System (PLC/SCADA) – For centralized operation and monitoring.

- Steel Structure Platforms – For maintenance and equipment access.

FAQ – Frequently Asked Questions

❓ What is the maximum input size for this limestone production line?

✔️ The system can handle raw materials up to 1200mm in size.

❓ Why choose a two-stage hammer crusher system instead of a jaw + cone setup?

✔️ Limestone is relatively soft. Using two heavy hammer crushers reduces investment, simplifies the process, and ensures higher shaping quality.

❓ What is the final product size?

✔️ The product size is customizable, generally 0–5mm, 5–10mm, 10–20mm, based on project requirements.

❓ Is this production line suitable for cement plant feedstock?

✔️ Yes, this design is ideal for producing limestone aggregates for cement manufacturing.

❓ Can this setup be customized for other capacities?

✔️ Absolutely. We offer custom configurations for 300TPH to 2000TPH limestone crushing lines.

Get a Custom Limestone Production Line Quote

Whether you’re building a cement plant or supplying high-quality aggregates for construction, we can help you design a cost-effective, high-capacity limestone crushing solution tailored to your needs.

👉 Contact Us Today for expert consultation and equipment pricing.