Must-Know! 8 Common Jaw Crusher Failures and How to Fix Them

Jaw crushers are widely used as primary and secondary crushers in mining, construction materials, and infrastructure projects due to their simple structure, large crushing ratio, high reliability, easy maintenance, and low operational costs. However, because they often operate under heavy loads and harsh conditions, failures are inevitable.

To minimize downtime and production losses, it’s essential for equipment operators and maintenance personnel to understand the 8 most common jaw crusher failures and their solutions. We’ve consulted with front-line technicians and compiled the following troubleshooting guide for your reference.

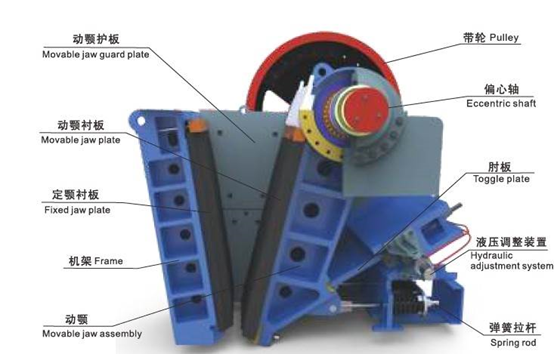

1. Flywheel Rotates, But Jaw Stops Moving

Symptoms:

The jaw suddenly stops moving during operation; a cracking sound is heard, and the flywheel continues to spin.

Possible Causes:

- Broken tension spring

- Broken toggle rod

- Non-crushable material entered the chamber, breaking or dislodging the toggle plate

Solutions:

- Replace the tension spring

- Replace the toggle rod

- Remove the damaged toggle plate and install a new one correctly

2. Crushing Chamber Blocked, High Motor Current

Symptoms:

Material accumulates in the chamber, causing the motor to draw excessive current.

Possible Causes:

- Oversized rocks jammed in the chamber

- Discharge conveyor malfunction

- Sticky material buildup, excessive feed

Solutions:

- Stop the machine and remove jammed materials

- Repair or restart the discharge conveyor

- Adjust feeding rate, clean the discharge opening

3. Jaw Plates Loose, Striking Noise

Symptoms:

The fixed or moving jaw plate vibrates and produces knocking sounds.

Possible Causes:

- Loose or broken mounting bolts

- Worn or insufficient tension in the anti-loosening spring

Solutions:

- Tighten or replace bolts

- Adjust the discharge gap and secure the plates properly

4. Discharge Opening Adjustment Fails

Symptoms:

Inability to adjust the discharge port or material jams frequently.

Possible Causes:

- Misaligned adjustment wedge or shim

- Incompatible or non-original toggle plate

- Loose bolts or worn adjustment seat

Solutions:

- Re-adjust wedge or shim

- Replace with OEM parts

- Check and replace defective components

5. Broken Movable Jaw

Symptoms:

Cracks or fractures in the movable jaw body

Possible Causes:

- Excessive impact load

- Material defect

- Toggle plate failed to protect

- Narrow discharge or uneven feeding

Solutions:

- Replace movable jaw

- Use original parts with quality assurance

- Adjust discharge opening and feeding method

6. Bent or Broken Eccentric Shaft

Symptoms:

Eccentric shaft is visibly bent or fractured

Possible Causes:

- Uneven lifting during installation

- Prolonged overload operation

- Substandard shaft material or heat treatment issues

Solutions:

- Replace with high-quality eccentric shaft

- Control load and ensure suitable material hardness

- Avoid non-standard parts

7. Broken Toggle Plate

Symptoms:

Toggle plate snaps, causing machine shutdown

Possible Causes:

- Overload or non-crushable material

- Misaligned toggle plate installation

- Material fatigue or defect

Solutions:

- Replace the toggle plate

- Control feed size

- Ensure correct installation and material quality

8. Sudden Machine Shutdown (Stalling)

Symptoms:

Jaw crusher shuts down unexpectedly during operation, also known as “stalling”

Possible Causes:

- Discharge blockage

- V-belt slippage

- Seized eccentric shaft

- Low voltage or bearing damage

Solutions:

- Clear blocked materials

- Adjust or replace the drive belt

- Replace bearing or shaft

- Ensure stable power supply

FAQ: Jaw Crusher Troubleshooting

Q1: What are the most common jaw crusher failures?

A1: The 8 main types include blocked chamber, flywheel spinning but jaw not moving, toggle plate breakage, eccentric shaft failure, jaw plate loosening, adjustment failure, sudden shutdown, and movable jaw damage.

Q2: How can I prevent jaw crusher stalling?

A2: Ensure consistent feeding, check for discharge clearance, avoid non-crushables, and monitor motor load and voltage.

Q3: What does a broken toggle plate indicate?

A3: It often indicates an overload or improper function of the safety mechanism; check toggle material and replace if defective.

Need Help? Contact Our Technical Team

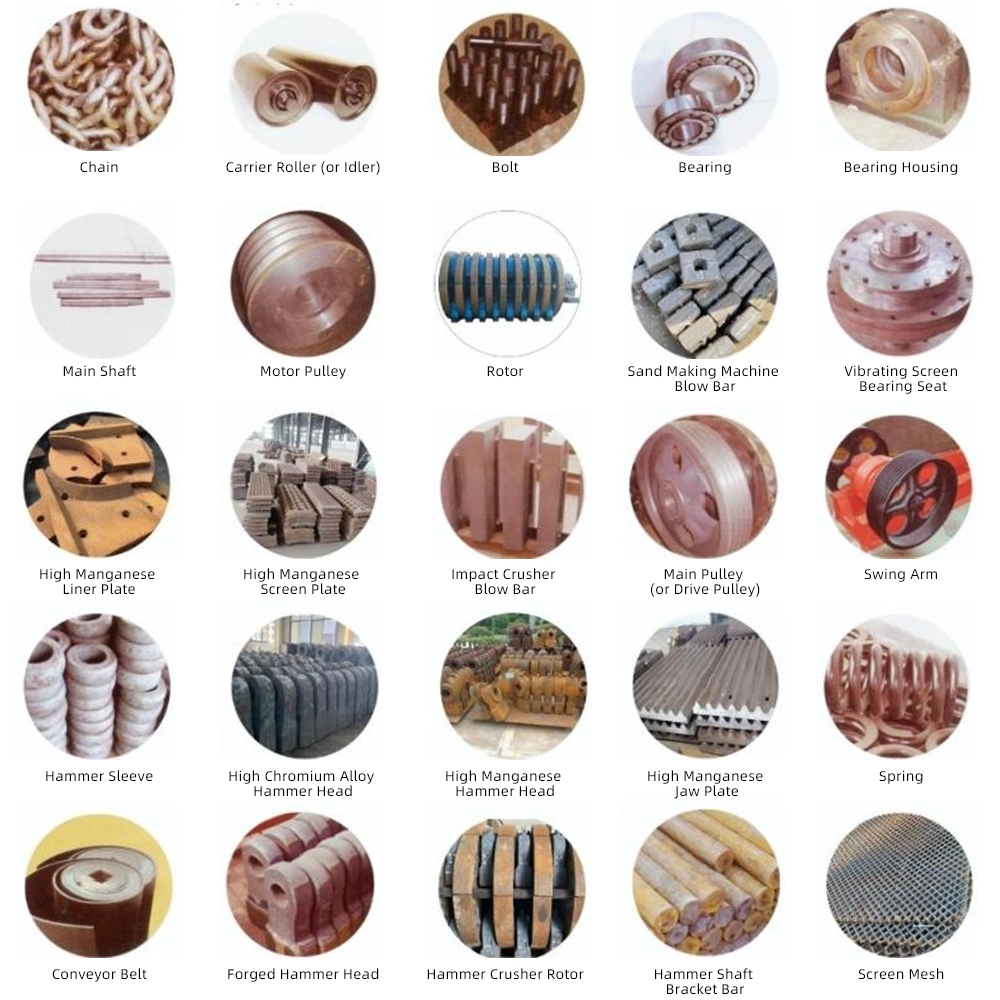

Experiencing any of the issues above? We provide OEM spare parts, remote diagnosis, on-site repair support, and customized crushing solutions.

👉 Contact Us Now for fast assistance from our expert engineers.