Smart Quarrying and Mine Automation Design Plan: Building a Safe, Efficient, and Green Future Mine

Building a smart mine is a crucial step in the transformation and upgrading of the modern quarrying industry. By introducing cutting-edge technologies such as IoT, big data, artificial intelligence, cloud computing, 5G communication, and automation control, smart quarrying combined with mine automation can achieve safe, efficient, green, and sustainable intelligent mining. The following presents a phased design plan for smart quarry and mine automation development.

I. Core Project Objectives

- Enhanced Safety: Reduce high-risk manual operations, promote unmanned and intelligent mining applications, and establish smart monitoring and early-warning systems.

- Higher Efficiency: Improve equipment utilization (OEE), optimize production processes, lower energy consumption, and stabilize product quality through mine automation.

- Refined Management: Real-time monitoring of personnel, equipment, energy consumption, and costs, enabling data-driven decision-making for smart quarrying.

- Green and Eco-Friendly: Optimize blasting design, reduce dust and noise, recycle wastewater, and build a green quarrying environment.

- Sustainable Growth: Extend mine service life, improve resource utilization, and shape the image of a responsible, modern intelligent mining enterprise.

II. Phased Construction Roadmap

Phase 1: Infrastructure and Sensing Systems

- Establish fiber optic backbone, 5G private networks, and Wi-Fi6 coverage to ensure stable communication.

- Deploy smart sensing devices such as GPS/BeiDou positioning, slope monitoring, HD video surveillance, and environmental monitoring stations to support smart quarrying.

- Build data centers, edge computing nodes, and cloud platforms as the digital foundation of mine automation.

- Develop 3D geological models and GIS platforms to provide data support for intelligent mining.

Phase 2: Digitalization and Partial Automation

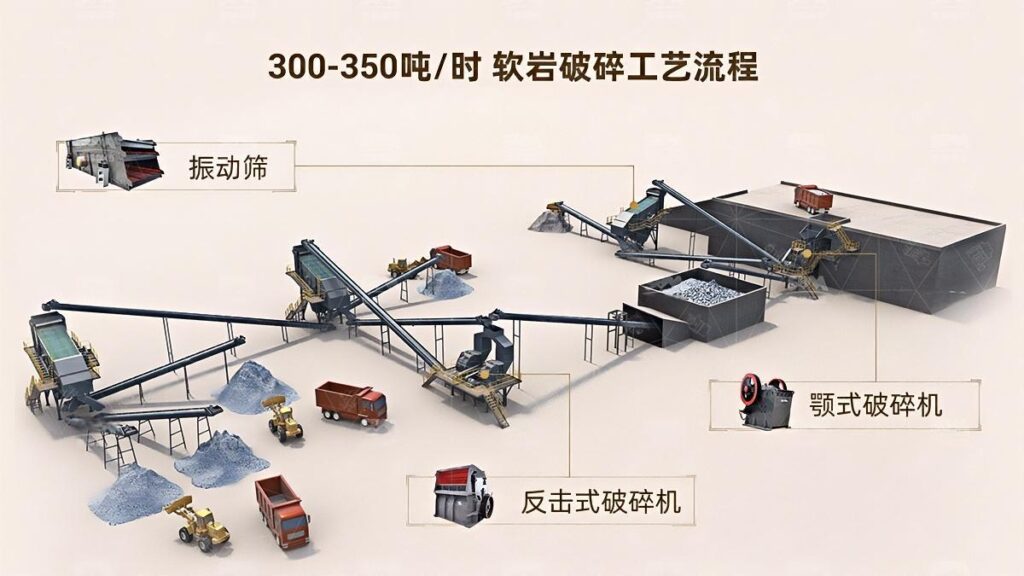

- Implement an intelligent production execution system to digitize the entire process from blasting, excavation, and transportation to crushing and shipping.

- Establish an intelligent dispatching system based on real-time positioning and production data to optimize equipment and vehicle routes, enhancing mine automation.

- Apply predictive maintenance by using sensors to monitor equipment health and reduce downtime.

- Create a centralized safety and environmental monitoring center for real-time risk warnings and emissions management.

- Apply remote control and automation in crushing and screening plants, and pilot intelligent mining with automated loading systems.

Phase 3: Deep Integration and Advanced Intelligence

- Build a digital twin mine to simulate production, compare plans, and conduct emergency drills, further improving smart quarrying.

- Use AI to optimize blasting parameters, ore blending, and energy efficiency, boosting both mine automation and intelligent mining performance.

- Deploy remote operation and unmanned systems such as autonomous mine trucks and teleoperated excavators in high-risk areas.

- Utilize big data platforms for multi-dimensional analysis to support management decisions.

- Establish an energy management system to optimize power use and achieve low-carbon mining.

Phase 4: Continuous Optimization and Ecosystem Collaboration

- Continuously optimize smart quarrying systems based on operational feedback.

- Introduce emerging technologies such as blockchain for traceability, metaverse-based training, and edge AI chips to enhance intelligent mining.

- Integrate with supply chain systems to achieve end-to-end traceability and intelligent logistics.

- Expand smart solutions into office and living areas, building a fully integrated smart mining park.

- Develop knowledge bases and training programs to strengthen workforce skills in mine automation and intelligent mining operations.

III. Expected Benefits

- Safety Benefits: Reduce on-site exposure in hazardous environments by over 30%, significantly lowering accident risks.

- Production Benefits: Increase equipment efficiency by 10–20%, reduce energy consumption by 5–15%, and boost output by 10–25%.

- Management Benefits: Lower management costs, improve decision-making efficiency, and enhance transparency in smart quarrying.

- Economic Benefits: Reduce overall operational costs and shorten ROI cycles to 3–5 years.

- Environmental Benefits: Decrease dust and noise emissions, recycle wastewater, and promote eco-friendly intelligent mining.

- Social Benefits: Strengthen corporate image, improve working conditions, and drive industry-wide mine automation upgrades.

Conclusion

Smart quarrying represents the inevitable future of the mining industry. By adopting a phased and systematic mine automation approach, enterprises can gradually transition from digitalization to intelligence, and from automation to unmanned intelligent mining. This not only enhances safety and efficiency but also drives green, low-carbon development, laying a solid foundation for the sustainable future of mining.