GPC Series Heavy Duty Hammer Crusher – High-Efficiency Stone Crushing Solution

Discover the GPC Heavy Duty Hammer Crusher, an advanced crushing machine for limestone, basalt, and other minerals. Featuring large feed size, high finished product rate, durable alloy hammer heads, and low energy consumption. Ideal for mining, konstruksi, and metallurgy industries.

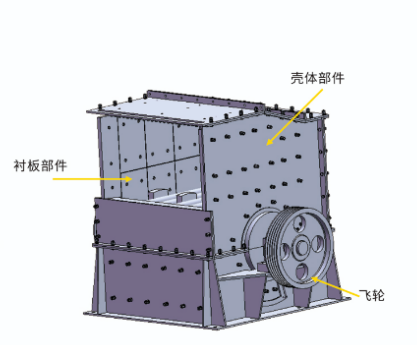

GPC Series Heavy Duty Hammer Crusher

The GPC Heavy Duty Hammer Crusher is a new generation product, carefully developed by our engineering team. It is widely applied in the crushing of limestone, basalt, and other medium-hard mineral materials. Compared with traditional two-stage crushing processes, the GPC crusher simplifies operations into one stage, ensuring large feed capacity, high finished product rate, and superior particle shape.

Equipped with imported high-alloy hammer heads, this crusher offers longer service life and lower maintenance costs compared with conventional hammer crushers.

Key Advantages of GPC Heavy Duty Hammer Crusher

- Large Feed Inlet & High Crushing Chamber – Suitable for large feed size and higher hardness materials with reduced powder content.

- Innovative Hammer Head Design – Strong impact resistance and durability.

- Round-Hole Screen Plate – Higher output capacity and better aggregate shape.

- Easy Maintenance – Rear body can be dismantled independently for quick servicing (especially for large models).

- Compact Structure – Strong overall rigidity and stability.

- Full Crushing Functions – Combines impact, counter-impact, and stone-on-stone crushing, leading to higher efficiency, less wear, and significant economic benefits.

Performance Features

- One-Time Crushing & Shaping: Handles medium-hardness materials in a single process, reducing investment by over 40% compared with impact crushers. Finished product yield increases by 20–30%, with less than 20–30% needle-like particles.

- Higher Capacity & Lower Energy Consumption: New process design ensures greater efficiency and better product quality compared with similar crushers.

- Superior Quality & Durability: Adopting the principle of “Quality First,” the GPC crusher offers outstanding performance and reliability.

Six Major Highlights

- Reinforced Body Structure – CO₂ gas shielded welding and vibration stress relief treatment.

- Durable Transmission Components – CNC machining and heat treatment for stronger toughness.

- High-Toughness Hammer Disk – Surfacing treatment for excellent wear resistance.

- Premium Alloy Hammer Head – High-chromium material with superior tensile strength and wear resistance.

- Advanced Screen & Guard Plate Design – Improved anti-impact and abrasion resistance.

- Modern Appearance & Enhanced Core Quality – Upgraded design for optimized performance.

Application Fields

The GPC Heavy Duty Hammer Crusher is widely used for primary and secondary crushing of materials with medium hardness or lower compressive strength.

- Mining industry – crushing ores and minerals

- Konstruksi & building materials

- Road & bridge engineering

- Chemical and metallurgical industries

Why Choose Hengtai GPC Hammer Crusher?

The GPC Heavy Duty Hammer Crusher represents a breakthrough in crushing technology. By combining the advantages of both hammer crushers and impact crushers, it delivers higher efficiency, stronger durability, and greater economic value for customers worldwide.

👉 Whether you need reliable performance in mining, konstruksi, or industrial applications, the GPC Series is your efficient crushing solution.