Granite Crushing Process

Introduction

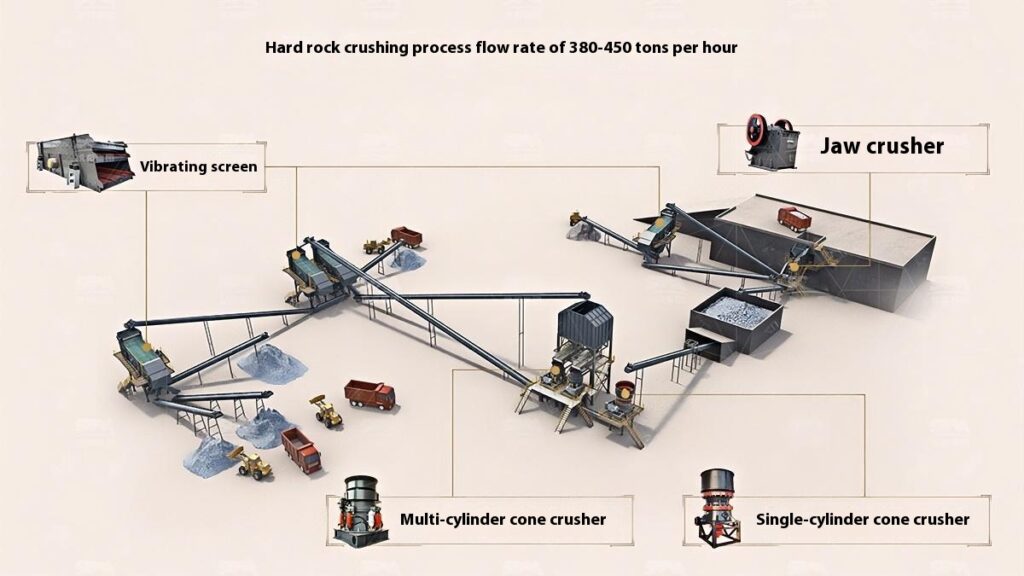

Granite Crushing Process Flow

Raw Granite → Vibrating Feeder → Jaw Crusher (Primary Crushing) → Cone Crusher (Secondary / Fine Crushing) → Vibrating Screen → Final Products / Sand Making (Optional)

Main Equipment Configuration

Vibrating Feeder: Feeds materials evenly and removes impurities.

Jaw Crusher: Used for primary crushing to break large pieces of granite.

Cone Crusher: Highly efficient and wear-resistant, suitable for secondary and fine crushing of hard materials.

Vibrating Screen: Separates aggregates into different particle sizes.

Belt Conveyor: Transports materials between equipment.

Sand Making Machine (optional, VSI Impact Crusher): Produces high-quality manufactured sand as needed.

Features of Granite Crushing

High hardness and strong wear resistance: Requires the use of wear-resistant alloy crushing components.

Large crushing ratio and excellent particle shape: Multi-stage crushing processes improve the quality of final products.

High level of automation: Intelligent control systems can be integrated to reduce labor costs.

Eco-friendly design: Equipped with dust suppression systems to control dust and noise emissions.

Common Applications

- 建筑骨料(Concrete aggregates)

- 高速公路路面基层(Road base materials)

- 铁路道砟(Railway ballast)

- 市政工程和城市基础设施(Urban infrastructure)

- 机制砂生产(Manufactured sand production)

FAQ – Frequently Asked Questions

Q1: What capacity configuration is needed for granite crushing equipment?

A: The required capacity depends on the size of your raw material and your daily processing volume. Typical capacity configurations range from 50 t/h to 1000 t/h.

Q2: Can the system produce manufactured sand?

A: Yes. By adding a VSI sand making machine after secondary crushing, finely crushed granite can be turned into high-quality manufactured sand suitable for concrete production.

Q3: Which is better for granite — cone crusher or impact crusher?

A: Granite is a hard material, so we recommend using a cone crusher, which offers longer wear part life and lower overall operating costs.

Contact Us for a Customized Solution

Looking for a complete granite crushing solution? We offer professional layout design, equipment selection, and turnkey service.

👉 Get a free solution and quotation:

🔗 https://slminingmachinery.com/#