Sand and Gravel Aggregates: The Core Materials in Construction Projects

What Are Sand and Gravel Aggregates?

Types of Sand and Gravel Aggregates

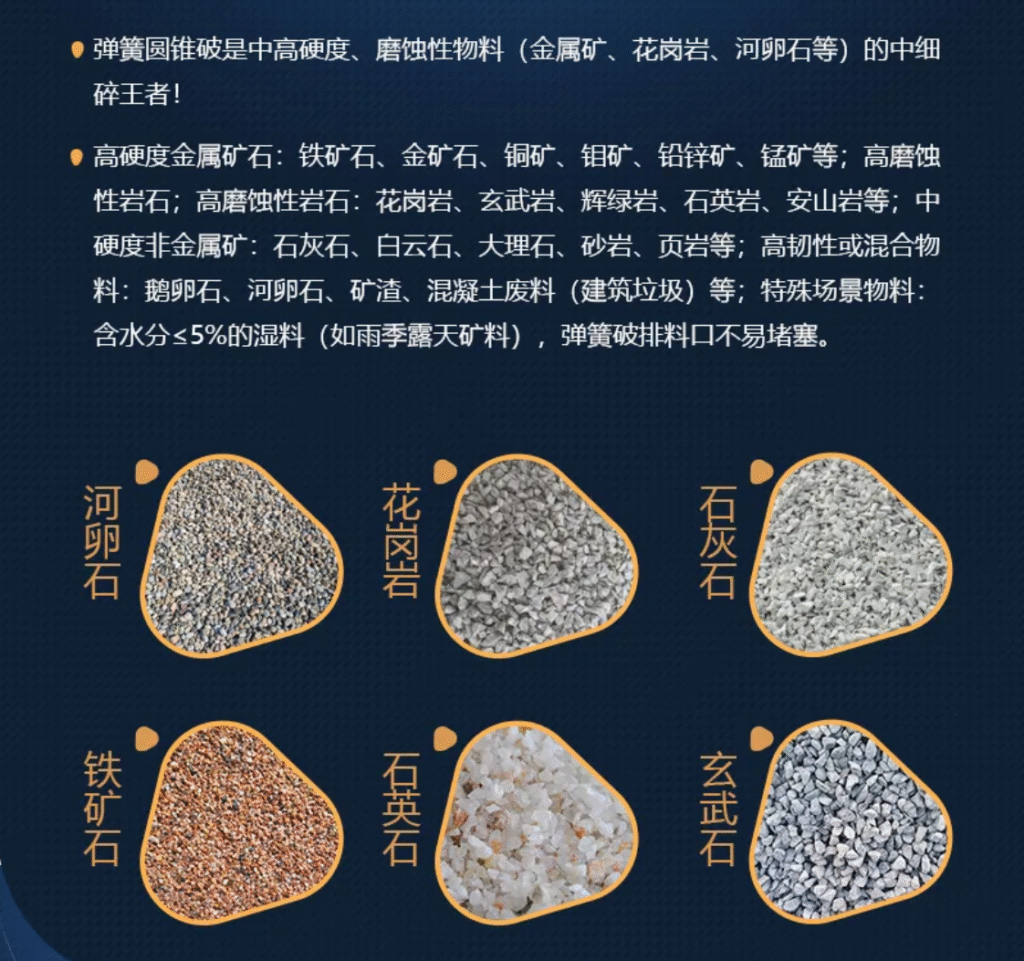

Aggregates can be classified based on particle size, source, and application:

1. By Particle Size:

- Coarse Aggregates (Crushed Stone, Pebbles): Typically larger than 4.75mm.

- Fine Aggregates (Natural Sand, Manufactured Sand): Usually smaller than 4.75mm.

2. By Source:

- Natural Aggregates: Derived from natural deposits such as rivers, lakes, and valleys.

- Manufactured Aggregates: Produced by crushing equipment such as crushers and sand-making machines, often used as a substitute for natural sand and gravel.

3. By Application:

- General Concrete Aggregates

- High-Performance Concrete Aggregates

- Road Base Aggregates

Production Process of Sand and Gravel Aggregates

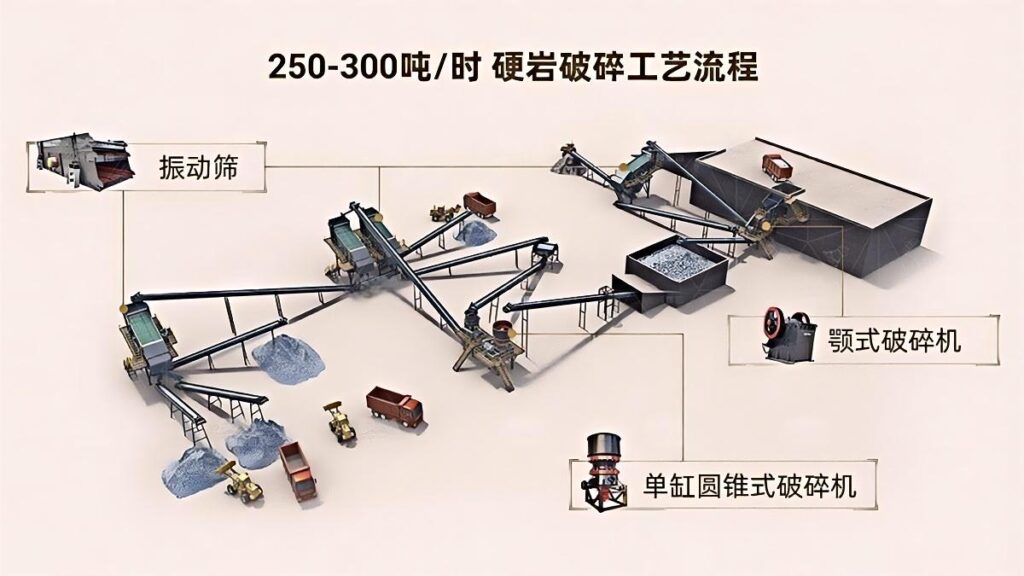

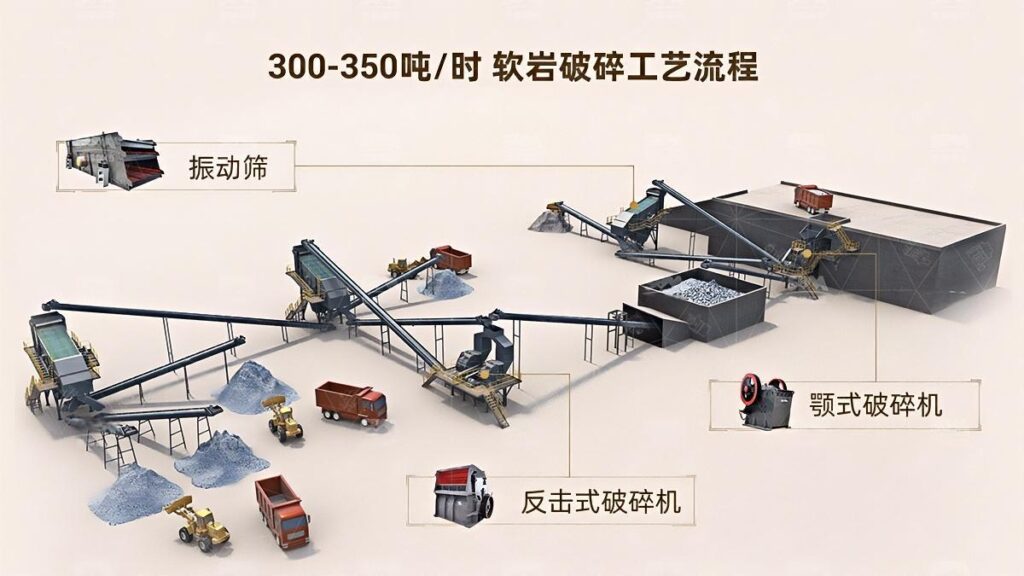

The production process of aggregates generally includes the following main steps:

- Raw Material Mining: Includes blasting and excavation at quarries.

- Primary Crushing: Large stones are crushed by jaw crushers.

- Secondary & Tertiary Crushing: Cone crushers, impact crushers, or hammer crushers are used for further crushing.

- Screening: Vibrating screens separate aggregates by particle size.

- Sand Making (if needed): Sand-making machines produce manufactured sand.

- Washing (optional): Removes impurities and improves cleanliness.

- Finished Product Storage & Transportation: Aggregates are sorted and stored for easy transport and use.

Applications of Sand and Gravel Aggregates

Aggregates are widely applied in various construction fields, including:

- Concrete production

- Water conservancy and hydropower projects

- Road and bridge construction

- High-rise building construction

- Subway and tunnel projects

- Municipal infrastructure projects

Quality Standards for Aggregates

High-quality aggregates should meet the following criteria:

- Uniform particle size and well-graded distribution

- Low impurity content and high cleanliness

- High strength and excellent compressive performance

- Compliance with national or industry standards, such as ASTM, ISO, or local regulations

Market Trends of Sand and Gravel Aggregates

With the rapid development of infrastructure projects, the demand for sand and gravel aggregates continues to rise. In particular, the application of manufactured sand has grown significantly. The industry is moving toward intelligent, green, and large-scale production.

Government policies also encourage the use of manufactured sand to reduce reliance on natural resources, promoting a sustainable approach in the aggregate industry.

Frequently Asked Questions (FAQ)

1. Why Is Manufactured Sand Becoming More Popular?

Manufactured sand offers abundant resources, controllable production, and excellent particle shape, effectively solving the shortage of natural sand while meeting the strict requirements for aggregate quality in construction.

2. How Can I Identify High-Quality Aggregates?

Key indicators include particle size distribution, clay content, durability, and compressive strength. It is recommended to choose products that have passed professional testing and certification.

3. What Equipment Is Needed for Aggregate Production?

Common equipment includes jaw crushers, cone crushers, impact crushers, vibrating screens, sand-making machines, washing machines, and feeders.

4. How Can Aggregate Production Be Environmentally Friendly?

By implementing closed production lines, dust suppression systems, and wastewater recycling technologies, producers can effectively minimize dust, noise, and wastewater, ensuring green and eco-friendly operations.

Conclusion

As fundamental materials in modern construction, the quality of sand and gravel aggregates plays a crucial role in ensuring the safety and durability of construction projects. Choosing high-quality, eco-friendly, and efficient aggregates not only improves project outcomes but also aligns with sustainable development goals.

If you are looking for premium sand and gravel aggregates or a complete aggregate production solution, feel free to contact us. We are ready to provide you with professional, efficient, and reliable services.