Heavy Hammer Crusher (Primary Impact Crusher): High-Efficiency One-Step Crushing Solution

In mining, aggregate production, and infrastructure projects, the demand for high crushing efficiency and excellent product shape continues to grow. The heavy hammer crusher, also known as the primary impact crusher, stands out as a new-generation high-performance crushing solution. With its “one-step forming” advantage, it is widely used for medium to low-hardness materials such as limestone, coal gangue, shale, and more.

This article explores the working principle, key advantages, application scenarios, and selection tips of heavy hammer crushers to help you evaluate their practical value.

1. What Is a Heavy Hammer Crusher?

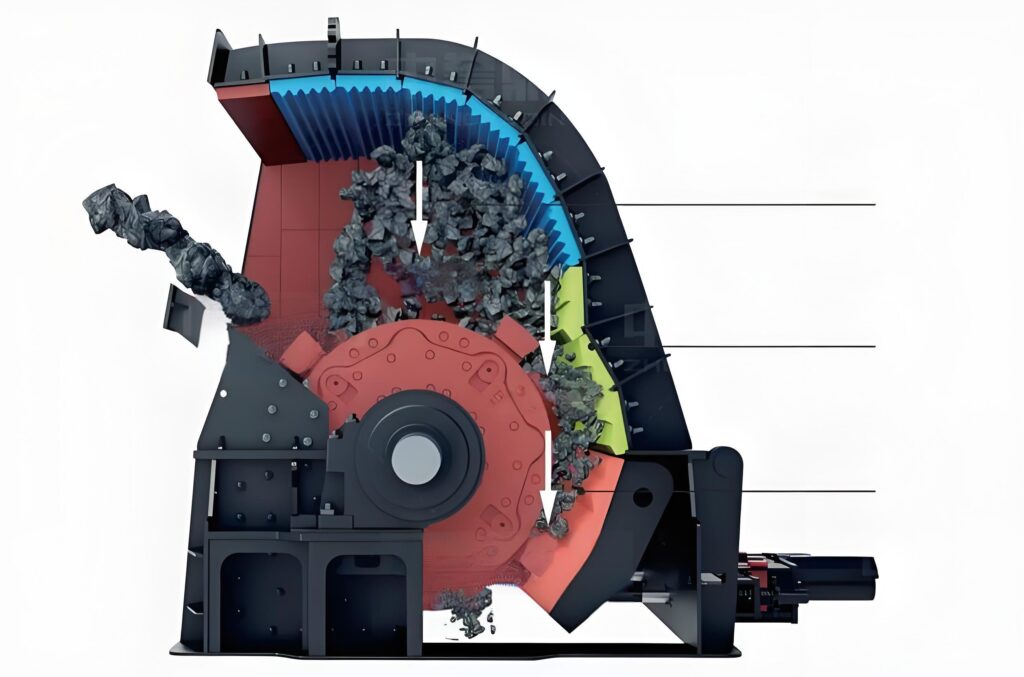

A heavy hammer crusher is a large-scale crushing machine that integrates primary crushing and shaping into one process. It utilizes high-speed rotating hammers to strike and shear the material with great force, achieving one-time crushing and forming. Compared with traditional combinations like jaw + impact crusher or jaw + cone crusher, the heavy hammer crusher features a simpler structure, shorter process flow, and significantly lower investment costs.

2. Principio de trabajo

Raw materials enter the crushing chamber through the feeding port and are struck repeatedly by high-speed rotating hammers. The materials are broken quickly and thrown against the impact plate and screen bars. Qualified materials are discharged directly, while oversized pieces remain in the chamber for further crushing.

This continuous impact and screening process results in uniform particle size, cubic shape, and reduced powder content—greatly improving the quality of finished aggregates.

3. Key Advantages of the Heavy Hammer Crusher

- One-Step Crushing, Lower Investment

No need for secondary crushing equipment—significantly reduces both initial equipment costs and operating expenses. - Excellent Product Shape

Final aggregates are cubic with uniform grain size—ideal for high-standard construction applications such as highways, railways, and concrete production. - High Crushing Ratio and Output

Crushing ratio up to 15–20, replacing two-stage crushing systems with a single machine. - Compact Design and Easy Maintenance

Hydraulic opening system simplifies maintenance. Wear-resistant hammer heads and liners extend service life. - Strong Material Adaptability

Capable of crushing materials with higher moisture content, reducing the risk of clogging.

4. Typical Application Scenarios

- Cement Raw Material Crushing: Ideal for medium-hard limestone and similar materials.

- Construction Aggregate Production: Delivers excellent particle shape and gradation.

- Coal Gangue / Shale Processing: Stable output with low energy consumption.

- Infrastructure Projects (Highways/Railways): Adjustable output sizes meet a variety of material standards.

5. Sample Technical Parameters (Customizable)

| Modelo | Tamaño máximo de alimentación (mm) | Output Size (mm) | Capacidad (T/H) | Power (KW) |

|---|---|---|---|---|

| PCZ1308 | ≤600 | ≤40 | 100–200 | 132 |

| PCZ1615 | ≤1000 | ≤40 | 300–600 | 315 |

| PCZ1720 | ≤1200 | ≤50 | 600–1000 | 500 |

(*Note: Custom configurations available based on material type and capacity requirements.)

6. Selection Tips

When choosing a primary impact crusher, consider the following factors:

- Material Properties: Best suited for medium and soft materials like limestone and coal gangue.

- Production Capacity: Choose the appropriate model based on daily or annual throughput.

- Output Specifications: Required particle size and shape for your application.

- Material Moisture: For high-moisture materials, additional de-dusting or anti-blocking systems may be needed.

- Production Line Compatibility: Consider integration with screening, conveying, or washing systems.

7. Conclusion

The heavy hammer crusher is a powerful, efficient, and versatile crushing solution, combining high output with outstanding shaping performance. Its simplified process design, reliable operation, and excellent end-product quality make it a popular choice in aggregates, cemento, and mining industries.

If you are looking for a cost-effective, one-step crushing solution, the heavy hammer crusher is a top contender.

Want to get a custom quotation, CAD drawings, or case studies?

👉 [Hogar – Soluciones de trituración premium para minería global & Construcción]