Common Hammer Crusher Failures: Causes and Solutions

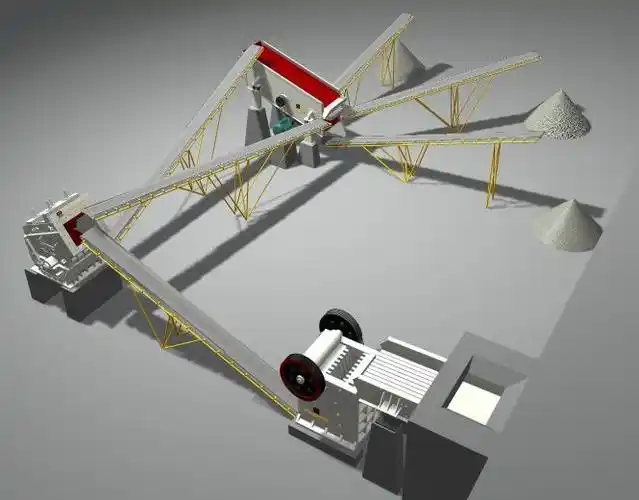

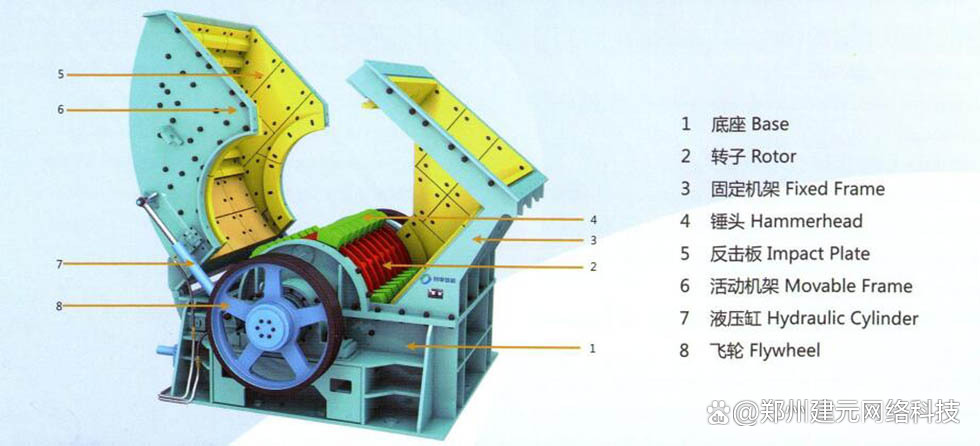

Hammer crushers are widely used in mining, building materials, metalurgia, and other industries. With advantages like simple structure, high crushing ratio, and high production efficiency, they are favored by many users. However, long-term use can lead to various operational failures that may affect productivity or cause equipment damage.

In this article, we’ll explore the most common hammer crusher failures, their underlying causes, and effective troubleshooting methods to help you ensure optimal machine performance and extended service life.

1. Common Hammer Crusher Severe Hammer Head Wear

Symptoms:

Reduced crushing efficiency, oversized output, increased vibration.

Causes:

- Low-quality or non-wear-resistant hammer head materials.

- Prolonged high-intensity operation.

- Failure to replace or rotate hammers regularly.

Solutions:

- Use wear-resistant materials such as high-chromium alloy hammers.

- Inspect hammers frequently and replace or rotate them as needed.

- Adjust rotor speed and feeding rate to avoid overloading.

2. Common Hammer Crusher Overheating Shaft or Damaged Bearings

Symptoms:

Unusual noise during operation, abnormally high shaft temperature.

Causes:

- Insufficient or contaminated lubrication.

- Improper bearing installation or incorrect clearance.

- Dust ingress causing bearing wear.

Solutions:

- Maintain proper lubrication and replace grease/oil regularly.

- Ensure correct installation with proper axial and radial clearance.

- Use seals to prevent dust contamination.

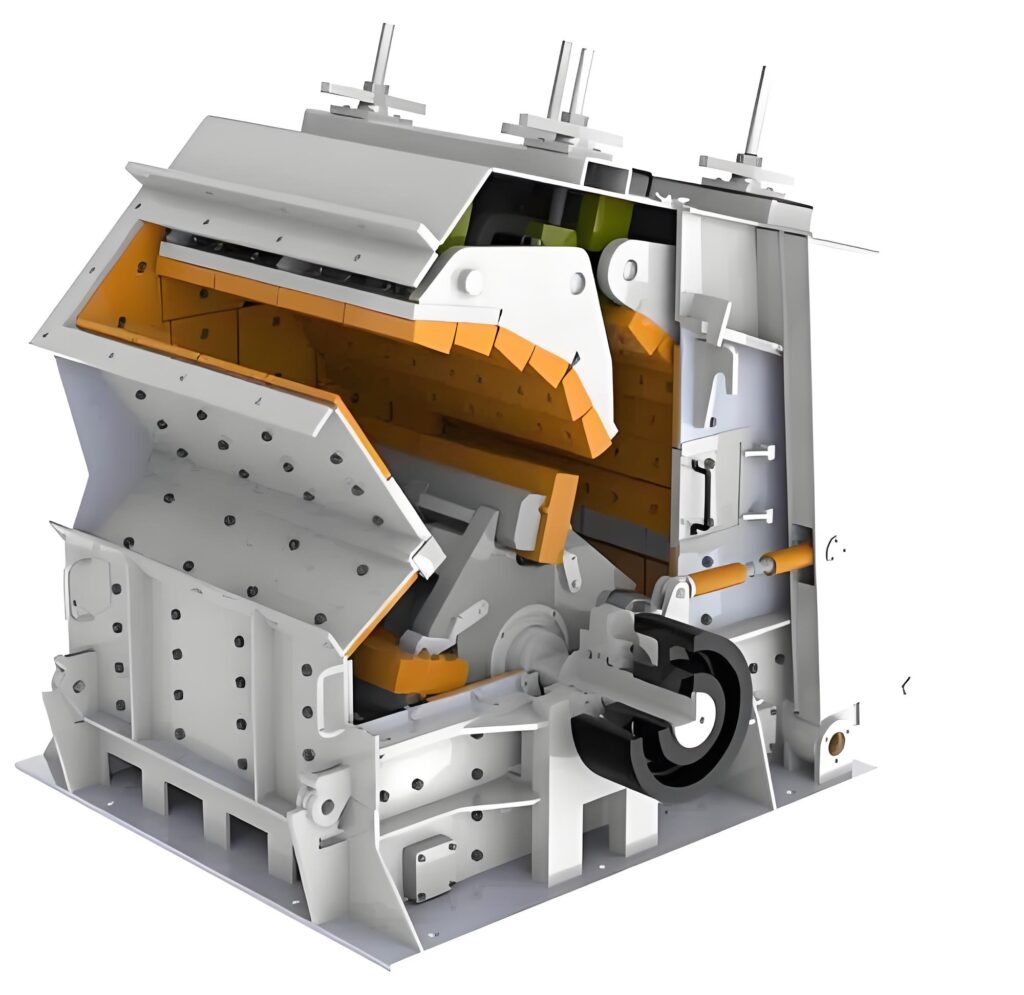

3. Excessive Vibration During Operation

Symptoms:

Severe shaking, unstable operation.

Causes:

- Uneven hammer distribution causing rotor imbalance.

- Loose foundation bolts or unstable base.

- Bent rotor shaft or detached parts.

Solutions:

- Ensure uniform hammer weight and perform dynamic balancing if needed.

- Check and tighten foundation bolts.

- Replace damaged parts and straighten or replace the rotor shaft.

4. Common Hammer Crusher Uneven Output or Material Blockage

Symptoms:

Inconsistent particle size, frequent shutdowns.

Causes:

- Worn or clogged screen plates.

- Improper gap between hammers and screen plates.

- Oversized feed material exceeding design capacity.

Solutions:

- Clean or replace screen plates regularly.

- Adjust hammer-to-screen gap (typically 15–30mm).

- Control feed size and avoid overloading.

5. Common Hammer Crusher Abnormal Motor Load

Symptoms:

Hard start, high current, tripping breakers.

Causes:

- Rotor blockage or material stuck in crushing chamber.

- Motor power mismatch with load.

- Electrical control system malfunction.

Solutions:

- Clear the crushing chamber of blockages.

- Match motor power to actual load requirements.

- Inspect control circuits and ensure protection systems are working.

Conclusion: Preventive Maintenance Is Key

Stable operation of a hammer crusher depends heavily on routine inspection and preventive maintenance. We recommend establishing a regular inspection schedule, focusing on:

- Daily: Check bolts and lubrication system before each shift.

- Weekly: Inspect hammer wear, screen condition, and rotor alignment.

- Monthly: Record vibration levels and motor current to detect early failures.

FAQ: Frequently Asked Questions

1. How often should hammer heads be replaced?

It depends on material hardness and operating time. On average, inspect every 100–300 hours of use.

2. Can a frequency inverter be used to control rotor speed?

Yes. A VFD allows for flexible speed control, optimizing output size and reducing energy consumption.

3. Does excessive vibration always indicate mechanical failure?

Not necessarily. Uneven feeding, loose base, or hammer imbalance can also cause abnormal vibration.

Need Help or a Quote?

Whether you’re looking to purchase a hammer crusher, customize a crushing solution, or get expert support…

Our technical team will get back to you with a tailored solution within 24 hours.