Metal Ore Crushing Solutions: Efficient, Economical, and Intelligent Solutions

What Is Metal Ore Crushing?

Common types of metal ores for crushing include:

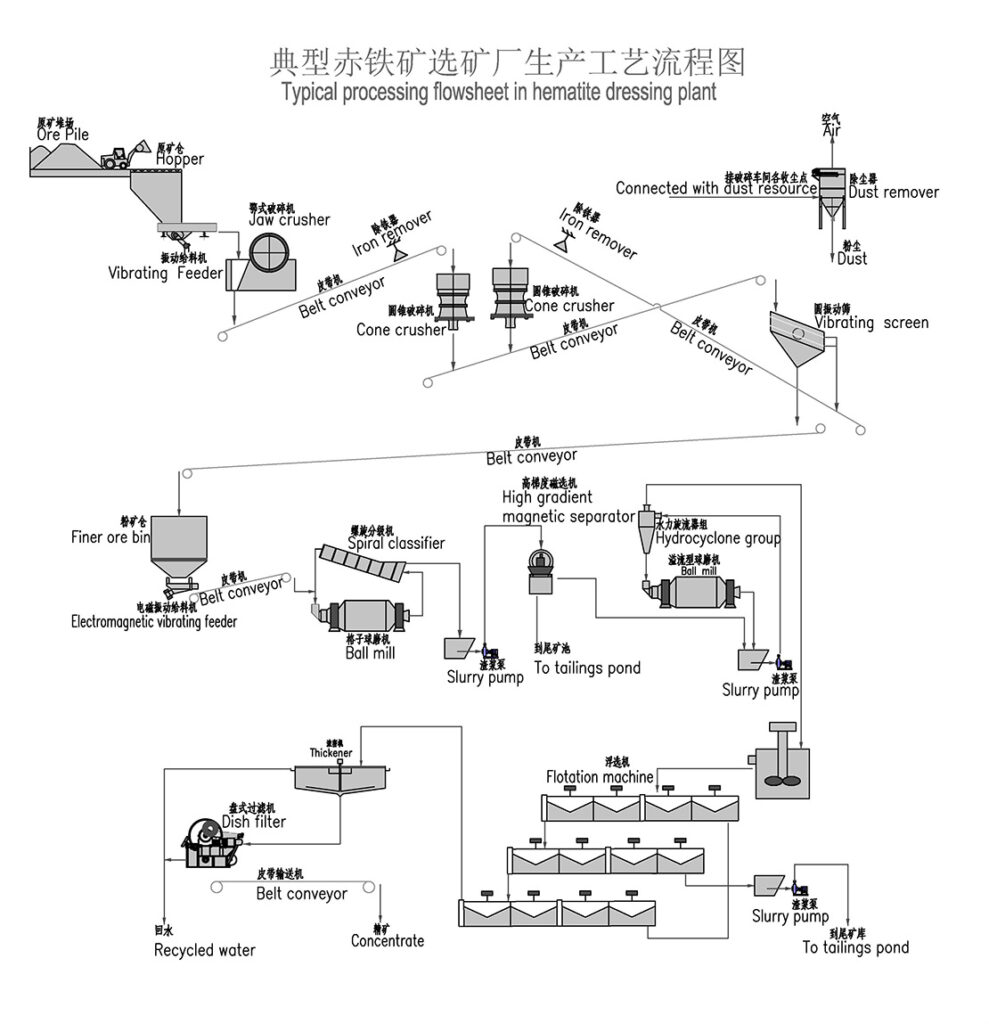

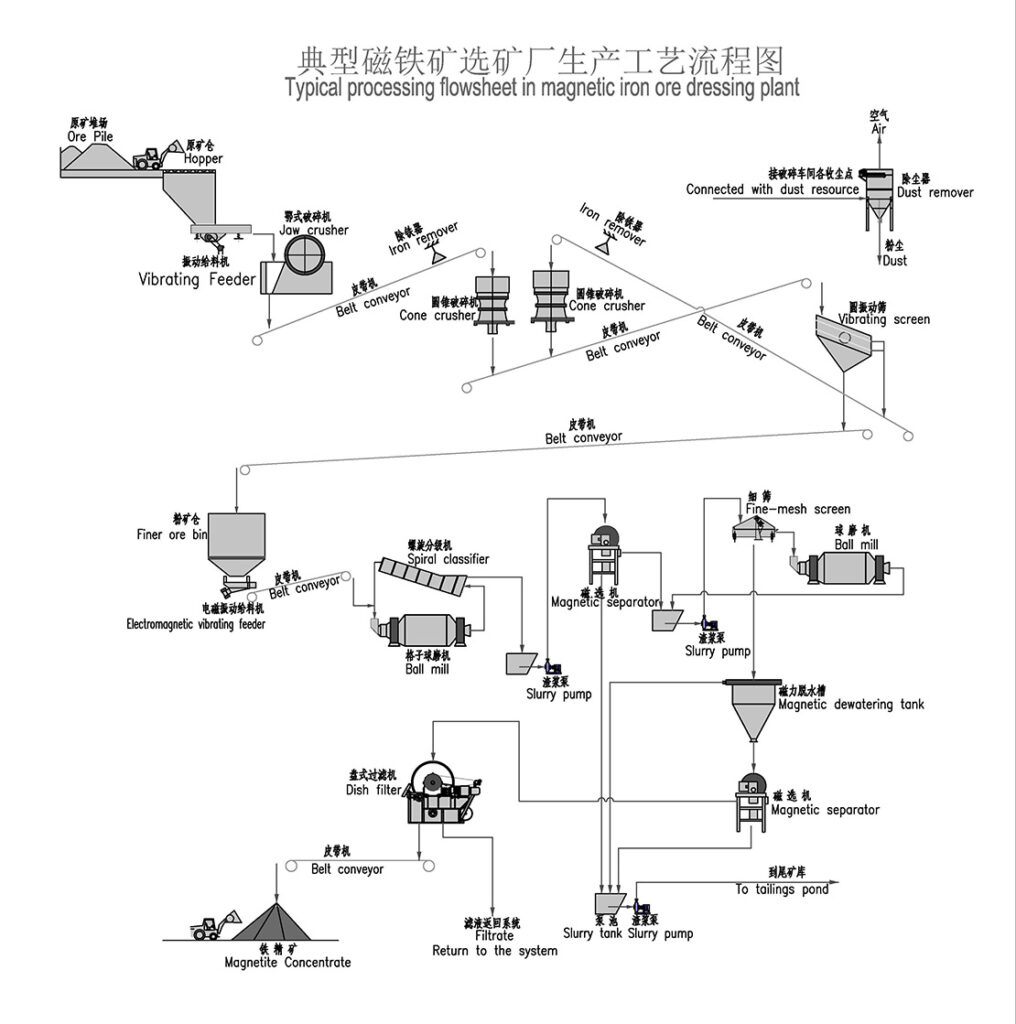

- Iron Ore

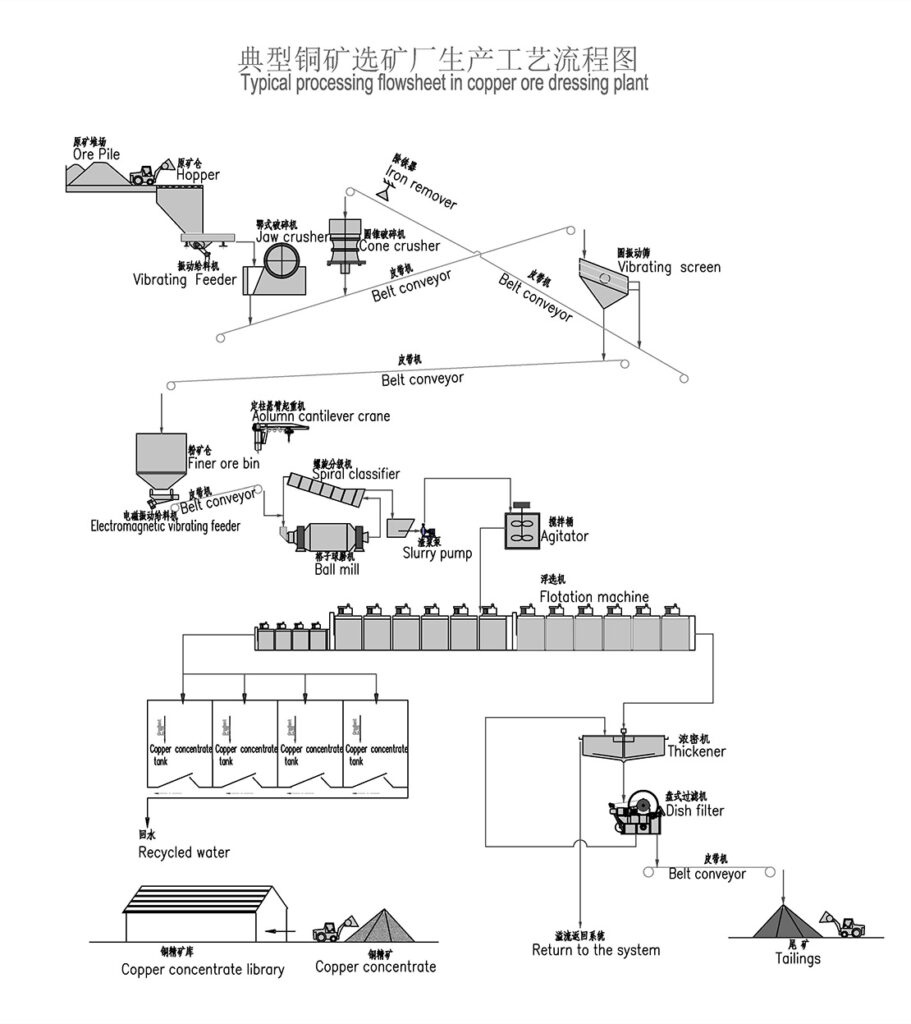

- Copper Ore

- Bauxite (Aluminum Ore)

- Nickel Ore

- Lead and Zinc Ores

- Gold and Silver Ores

Metal Ore Crushing Process Design

Based on the physical properties of different metal ores—such as hardness, moisture, particle size, and clay content—crushing process designs typically follow the principle of multi-stage crushing, graded screening, and high efficiency.

Standard Metal Ore Crushing Process:

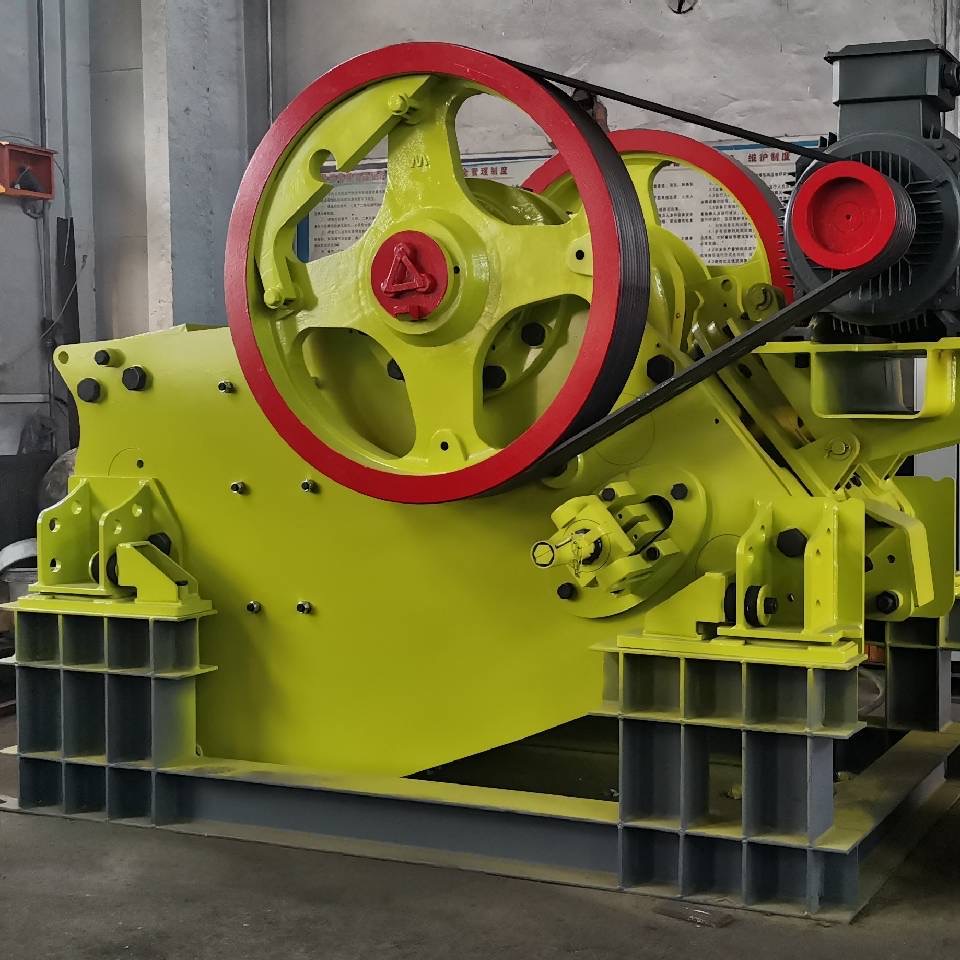

- Primary Crushing

- Common Equipment: Kiefer Curser

- Funktion: Breaks large chunks of ore into medium-sized pieces for further processing

- Features: High capacity and excellent adaptability to hard ores

- Secondary/Intermediate Crushing

- Common Equipment: Cone Crusher or Impact Crusher

- Funktion: Further reduces ore size for better fine crushing results

- Features: Large reduction ratio, high output, and good particle shape

- Screening

- Common Equipment: Vibrierender Bildschirm

- Funktion: Separates different particle sizes and recirculates oversized materials

- Fine Crushing or Tertiary Crushing(Optional)

- Common Equipment: High-Efficiency Fine Crusher or VSI Sand Maker

- Suitable for applications requiring finer particle sizes or superior particle shapes

Recommended Equipment Combinations for Metal Ore Crushing

| Ore Type | Recommended Equipment Combination |

|---|---|

| Iron Ore | Kiefer Curser + Cone Crusher + Vibrierender Bildschirm |

| Copper Ore | Kiefer Curser + Cone Crusher / Impact Crusher + Vibrierender Bildschirm |

| Bauxite | Kiefer Curser + Impact Crusher + Vibrierender Bildschirm |

| Nickel Ore | Kiefer Curser + Cone Crusher + Screening -Geräte |

| Lead and Zinc Ore | Kiefer Curser + Cone Crusher + Vibrierender Bildschirm + Fine Crusher |

| Gold and Silver Ore | Kiefer Curser + Impact Crusher / Cone Crusher + Vibrierender Bildschirm + Fine Crusher |

Key Points for Crushing Solution Design

- Ore Hardness & Abrasiveness: Hard ores require wear-resistant equipment such as cone crushers; medium-to-low hardness ores can use impact crushers.

- Feed Size & Output Requirements: Determine the number of crushing stages and equipment models accordingly.

- Production Capacity: Select equipment based on target tonnage to ensure production efficiency.

- Particle Shape Requirements: For high-quality particle shapes, additional fine crushing or shaping processes may be needed.

- Environmental & Automation Needs: Incorporate dust control, noise reduction, and automated control systems for green and intelligent production.

Advantages of Our Metal Ore Crushing Solutions

- High Efficiency & Energy Saving: Advanced crushing technologies reduce energy consumption and improve output.

- Strong Wear Resistance: Key components are made from wear-resistant materials to withstand harsh mining environments.

- Stable Production Capacity: Compact design and smooth operation ensure continuous production.

- Excellent Particle Shape: Well-graded final products improve mineral processing and smelting efficiency.

- Intelligent Automation: Supports remote monitoring, fault alerts, automatic lubrication, und mehr.

Application Cases

We have provided crushing solutions for various metal mining projects, including iron ore, copper ore, nickel ore, and gold ore, with equipment exported to Southeast Asia, Africa, the Middle East, and South America—earning widespread customer recognition.

Frequently Asked Questions (FAQ)

1. How to Choose Metal Ore Crushing Equipment?

The selection depends on ore hardness, clay content, feed size, and production capacity. Jaw crushers, cone crushers, impact crushers, vibrating screens, and fine crushers are commonly used.

2. Does More Crushing Stages Always Mean Better Results?

Not necessarily. More stages increase investment and maintenance costs. The ideal solution balances cost and performance based on actual production needs.

3. How Can Metal Ore Crushing Be Environmentally Friendly?

By installing dust collection systems, sealed conveyors, and spray dust suppression systems, operations can meet environmental standards.

4. Is Equipment Maintenance Difficult?

Our equipment is designed for easy maintenance with simplified wear part replacements. We also provide detailed operation and maintenance manuals along with full technical support.

Conclusion

A well-designed metal ore crushing solution significantly boosts beneficiation efficiency, production capacity, and reduces operational costs. It also minimizes equipment wear and enables efficient, intelligent, and eco-friendly mineral processing.

If you are looking for professional, reliable metal ore crushing equipment and solutions, we are ready to assist you!

👉 Click Here to Contact Us Now for Free Consultation & Customized Quotations!