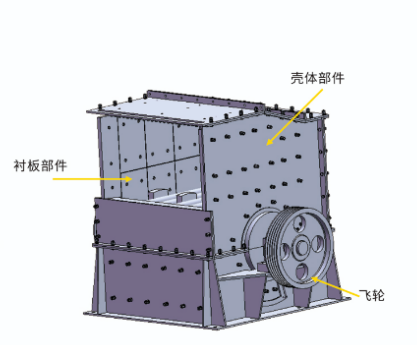

Crushing Equipment — Hammer Crusher

1. Overview

The hammer crusher is a machine that utilizes the high-speed rotation of hammers to impact materials, causing them to break along natural fissures, bedding planes, and weak cleavage surfaces. It is suitable for crushing brittle, medium-hard materials with low moisture content. Widely used in building materials, كيميائية, electric power, mining, and metallurgy industries, it is ideal for crushing limestone, coal, الصخر الزيتي, جبس, chalk, slate, coke, and similar materials.

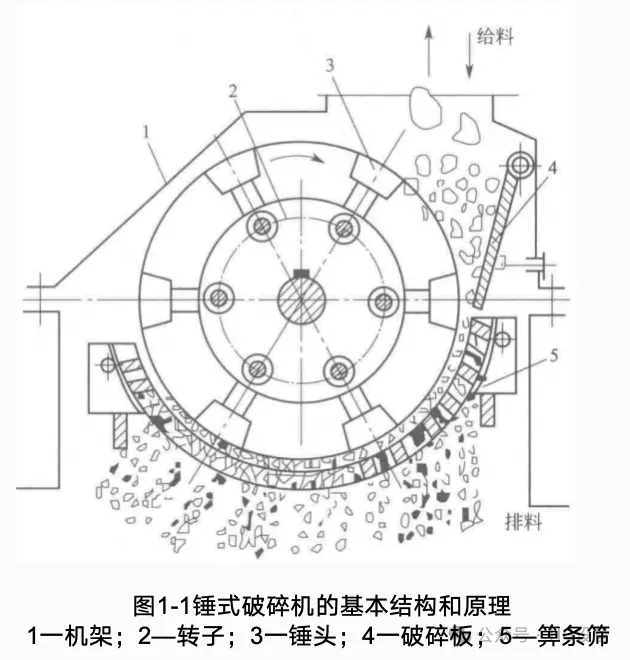

2. Basic Structure and Working Principle

The hammer crusher mainly consists of the frame, rotor, hammers, impact plates, and grate bars.

- Rotor: composed of the main shaft, discs, and hammers, forming the core component.

- Working Process: After entering the crushing chamber, materials are first impacted by the fast-rotating hammers and then strike the impact plates for secondary crushing. Smaller particles pass through the grate bars, while oversized materials continue to be impacted and ground until they reach the required size.

- Model Representation: Specified by rotor diameter D (مم) × length L (مم). For example, a 1000×800 hammer crusher has a rotor diameter of 1000 mm and an effective hammer length of 800 مم.

3. Types and Features

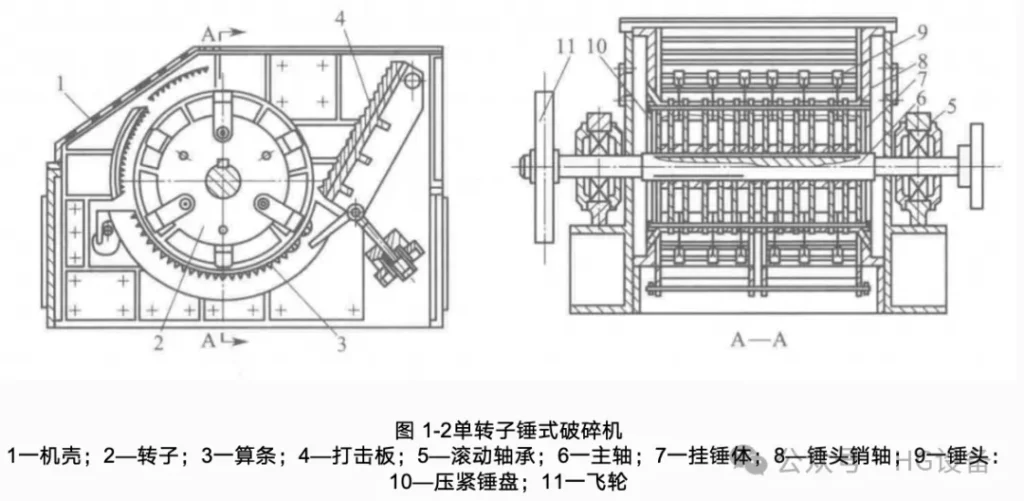

1) Single-Rotor Hammer Crusher

This is the most common design. It usually has multiple rows of hammers. The casing is welded in two sections with high-manganese steel liners inside. The rotor is supported on both ends by rolling bearings, driven by a motor through an elastic coupling, and equipped with a flywheel for stable operation. A curved grate bar is mounted beneath the rotor, with expanding slots for smooth discharge.

- Working Characteristics: Materials are impacted by hammers, then strike the impact plates or other particles. Fine particles pass through the grate slots, while oversized ones remain for repeated impact and grinding.

- Protective Measures: Hammers are freely suspended; when encountering uncrushable materials, they swing back to prevent damage. A safety pin mechanism disconnects the motor from the rotor in case of overload.

- Application: Suitable for brittle materials such as limestone, coal, جبس, and coke. Not suitable for sticky or wet materials, as blockage may occur.

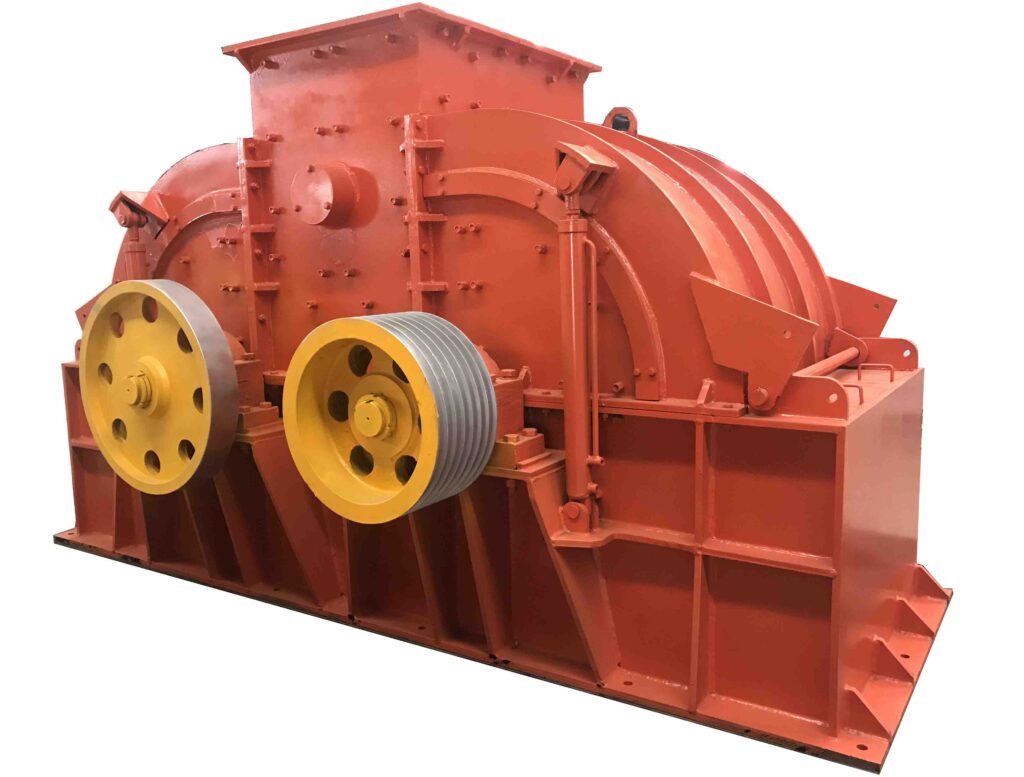

2) Double-Rotor Hammer Crusher

This crusher has two parallel rotors inside the casing, each driven by a separate motor in opposite directions. Hammers are arranged in staggered rows, and a bow-shaped grate basket with an anvil seat is installed below the feed inlet.

- Working Characteristics: Materials are first pre-crushed on the grate basket by hammer impact, then fall onto the anvil and grate bars beneath the rotors, receiving continuous hammering until discharged at the required size.

- Advantages: Large reduction ratio (up to 40), high production capacity equivalent to two single-rotor crushers, and high crushing efficiency.

- Application: Suitable for large blocks of medium-hard brittle materials. Not suitable for sticky or high-moisture materials due to grate clogging issues.

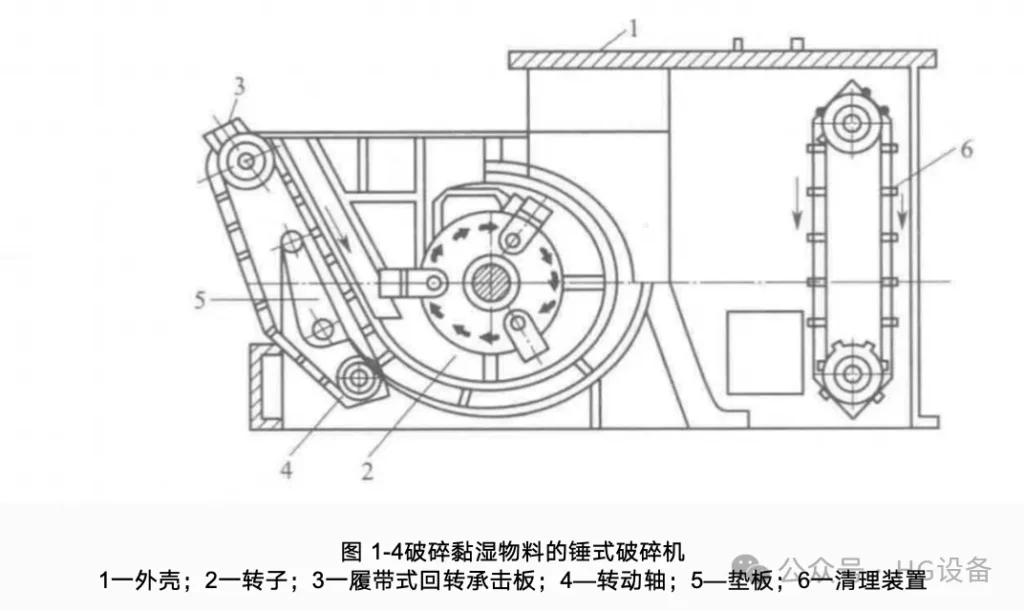

3) Hammer Crusher for Sticky and Wet Materials

Conventional hammer crushers are prone to clogging when handling sticky or wet materials. To overcome this, a specialized design has been developed. A track-type rotary impact plate, driven by a separate motor, is installed in front of the rotor. It prevents material buildup at the chamber inlet, while adhered material is swept off by the hammers. A vertical closed-loop chain cleaner with transverse scrapers, driven by another motor, is mounted behind the rotor to loosen accumulated material and scrape off deposits from the chamber walls.

- Structural Features: No grate bars under the rotor to avoid clogging; impact plate reinforced with a base plate to withstand hammer impact.

- Advantages: Capable of handling high-moisture and sticky materials, self-cleaning ability prevents blockage, ensuring reliable operation.

- Application: Suitable for sticky coal, الصخر الزيتي, جبس, clay-containing ores, and similar materials.

4. Comparison of Hammer Crusher Types

| Type | Structural Features | Advantages | Limitations | Suitable Materials |

|---|---|---|---|---|

| Single-Rotor | Single rotor with multiple rows of hammers; equipped with grate bars and impact plates; overload protection | Simple structure, سهولة الصيانة; impact + attrition crushing; high safety | Prone to clogging, unsuitable for high-moisture materials | Limestone, coal, جبس, coke |

| Double-Rotor | Two parallel rotors with staggered hammers; bow-shaped grate basket + anvil seat | Large reduction ratio (up to 40); high capacity; high efficiency | Not suitable for sticky or wet materials due to grate clogging | Large blocks of limestone, coal, الصخر الزيتي, ores |

| Sticky-Material Crusher | Rotary impact plate (independent motor); no grate bars; chain-type cleaning device | Handles sticky/wet materials; clog-free; self-cleaning capability | More complex structure, higher cost, relatively higher energy consumption | Sticky coal, الصخر الزيتي, جبس, clay-rich ores |

5. Conclusion

Hammer crushers are widely used due to their simple structure and high crushing efficiency. Depending on material properties and production requirements, different types can be selected:

- Single-rotor: economical solution for brittle materials.

- Double-rotor: efficient for large, hard blocks with high reduction ratios.

- Specialized wet-material crusher: designed for sticky and high-moisture materials, ensuring smooth operation without clogging.

Choosing the appropriate hammer crusher type can significantly improve production efficiency, reduce maintenance costs, and ensure stable operation of the processing line.