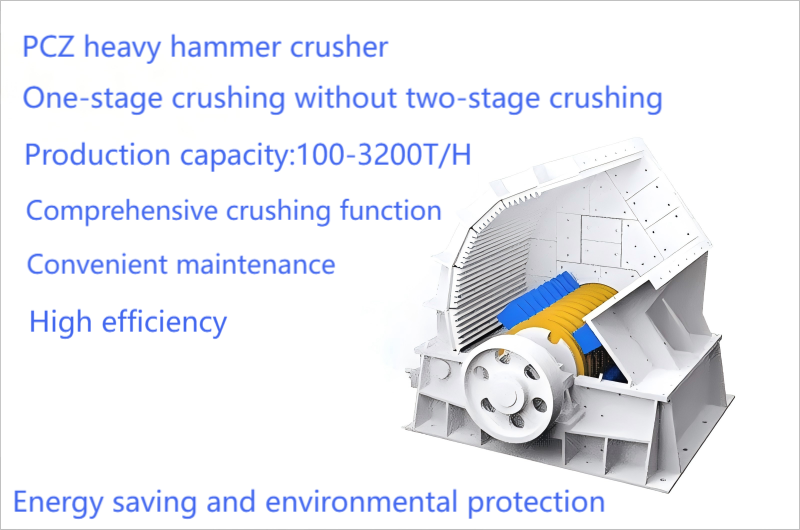

📌 Model: PCZ Heavy Hammer Crusher 3026

-

Maximum Feeding Size: 1400 mm

-

Discharge Size Range: 0–100 mm

-

Production Capacity: 1500–1800 t/h

-

Motor Power: 630 × 2 kW

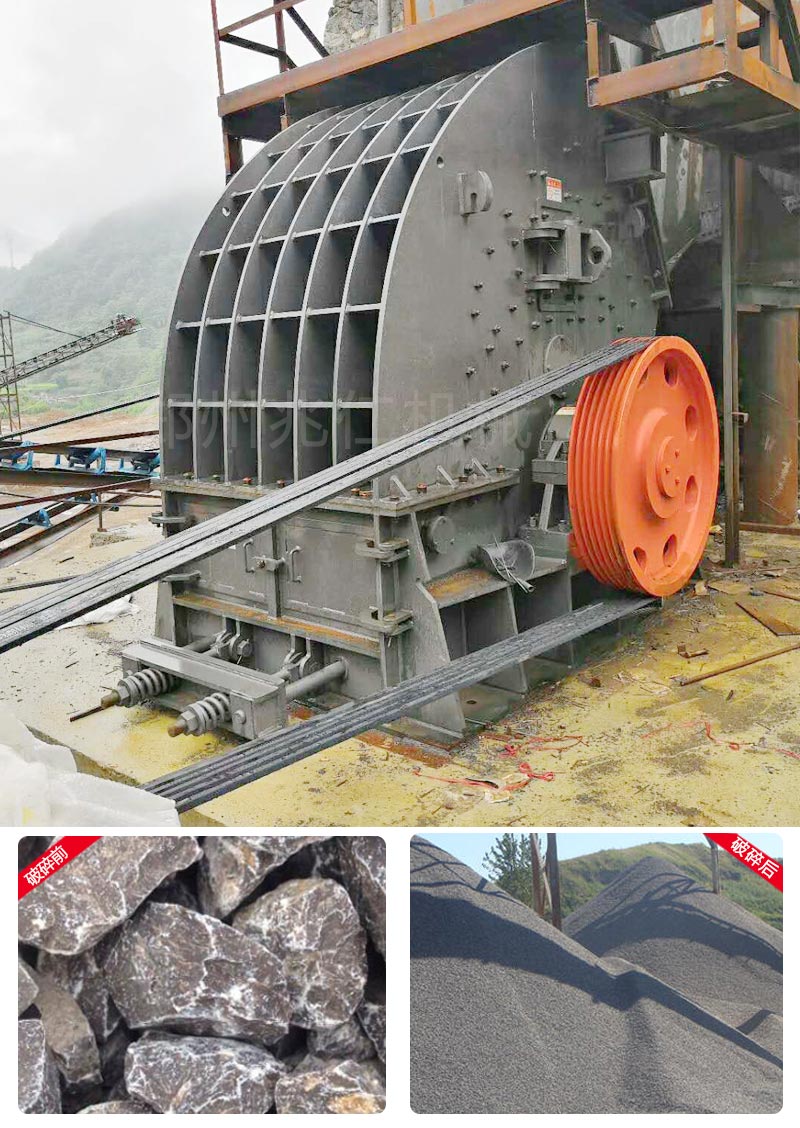

⚙️ Working Principle

The rotor disc equipped with hammers is driven by the motor to rotate at high speed. When material enters the crushing chamber, it is impacted by the fast-rotating hammers, propelled against the impact plates, and further crushed by collisions and friction among materials. Qualified material is discharged through the outlet, while oversized pieces are returned to the crushing zone for further reduction.

⭐ Key Features

-

Simple structure and stable operation

-

Large feeding size, high crushing ratio, and uniform output size

-

High-efficiency one-step crushing process

-

Wear-resistant parts with low maintenance requirements

-

High single-machine capacity (120–2000 t/h)

-

360° rotatable hammers reduce risk of frequent hammer breakage

-

Capable of one-time forming for finished products

🧱 Applicable Materials

The PCZ heavy hammer crusher is designed for medium-hard and brittle materials, with compressive strength typically below 150–200 MPa.

✅ Ideal Materials

-

Limestone – Typically <150 MPa; the most common and suitable material

-

Bluestone – Medium hardness, ≤200 MPa; very efficient crushing

-

Coal Gangue – High brittleness and low abrasiveness

-

River Pebbles / Cobbles – Suitable if compressive strength is ≤200 MPa

⚠️ Conditionally Applicable (Strength-Dependent)

-

Dolomite (≤200 MPa)

-

Sandstone (medium hardness)

-

Marble (≤200 MPa)

-

Low-abrasive basalt (requires strength verification)

❗ Limitations & Considerations

-

Compressive Strength Limit: Generally ≤150–200 MPa

-

Material Properties: Only suitable for brittle, medium-hard, and low-abrasive stone

-

Not Suitable For: High-hardness materials (e.g., granite, iron ore) unless verified

-

Calcium Content: Some models require ≥40% Ca content in the material

💡 Advantages

The PCZ heavy hammer crusher enables one-step crushing for materials with hourly output requirements below 600 tons. It eliminates the need for secondary crushing, reducing total costs by up to 40%. With a maximum feeding size of 1400 mm, it is highly effective for medium- and large-scale applications in mining, building materials, and chemical industries.

Note: Final model selection must be based on material-specific parameters such as compressive strength and abrasiveness index.

Reviews

There are no reviews yet.