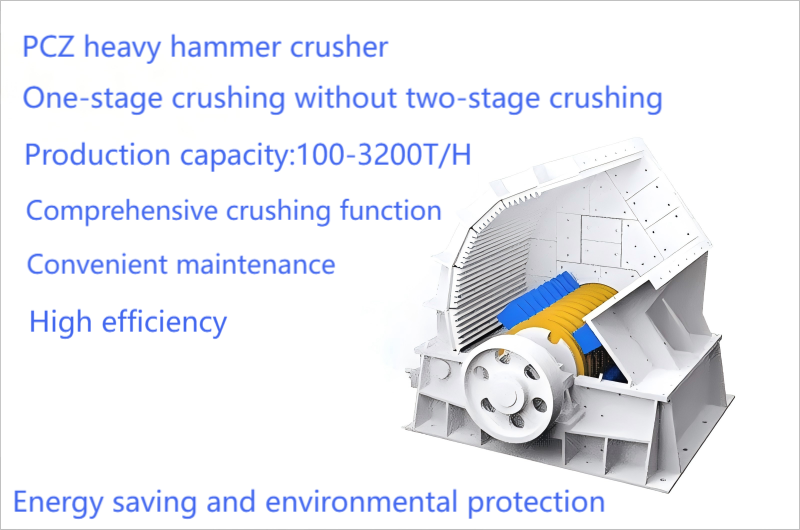

📌 Model: PCZ Heavy Hammer Crusher 2822

-

Maximum Feeding Size: 1000 mm

-

Discharge Size Range: 0–100 mm

-

Production Capacity: 1000–1200 t/h

-

Motor Power: 400 × 2 kW

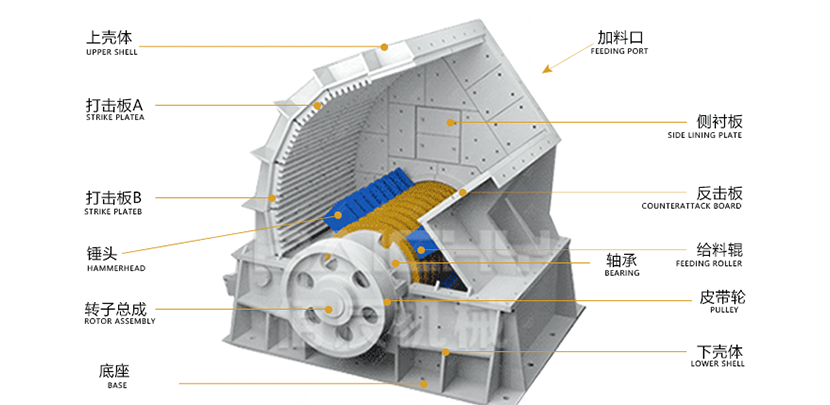

⚙️ Working Principle

The rotor disk of the PCZ Heavy Hammer Crusher, equipped with hammers, is driven by an electric motor to rotate at high speed. When material enters the crushing chamber, it is struck by the hammers, thrown against the impact plate, and further broken by collisions and friction among the particles. Qualified material is discharged through the bottom outlet, while oversized particles are recirculated back into the crushing zone for further reduction.

⭐ Key Features

-

Simple structure and stable operation

-

Large feed size, high crushing ratio, and uniform output particle size

-

Capable of producing finished product in one step; highly efficient

-

Wear-resistant components with easy maintenance

-

Large single-unit throughput (120–2000 t/h)

-

360° rotatable hammers reduce hammer breakage issues

-

One-step crushing and shaping process

🧱 Applicable Materials

PCZ heavy hammer crushers are ideal for medium-hard and brittle materials with compressive strength generally below 150–200 MPa.

✅ Primary Applicable Stone Types

-

Limestone – Typically <150 MPa; ideal for PCZ crushers

-

Bluestone – Medium hardness, ≤200 MPa; high efficiency

-

Coal Gangue – Highly brittle, low abrasiveness; excellent crushing performance

-

River Pebble / Cobble – Suitable if compressive strength ≤200 MPa

⚠️ Conditionally Applicable Materials (subject to strength limitations)

-

Dolomite (≤200 MPa)

-

Sandstone (medium hardness)

-

Marble (≤200 MPa)

-

Low-abrasiveness basalt (requires strength verification)

❗ Key Limitations

-

Compressive Strength Limit: ≤150–200 MPa depending on model

-

Material Nature: Only suitable for brittle, medium-hard, and low-abrasive stone

-

For high-hardness materials (e.g., granite, iron ore), use cautiously or consider cone crushers

-

Calcium Content: Some models require ≥40% calcium content in material

💡 Advantages of PCZ Crusher

The PCZ heavy hammer crusher can achieve one-step crushing and forming, especially effective for projects with throughput under 600 t/h, helping eliminate the need for secondary crushing and reducing total crushing cost by up to 40%. It supports large feed sizes (up to 1200 mm), making it highly suitable for medium to large-scale applications in mining, konstruksie, and chemical industries.

Note: Final model selection must consider specific material properties (e.g., compressive strength, abrasion index) for proper equipment matching.

Reviews

There are no reviews yet.