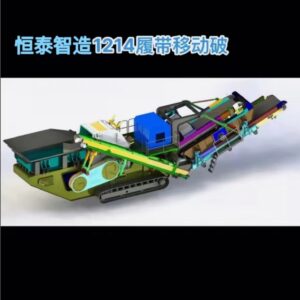

Crawler Mobile Crushing Plant

Product Introduction

The Crawler Mobile Crushing Plant is an advanced, high-efficiency crushing equipment that integrates feeding, crushing, screening, and conveying functions. Featuring a fully hydraulic drive system and powerful crawler chassis, this plant can easily navigate rough terrains and work efficiently in complex environments such as mining sites, construction waste recycling, and aggregates production. It is designed for flexible movement, fast deployment, and convenient operation, providing a highly efficient and cost-effective solution for on-site crushing tasks.

Crawler Mobile Crushing Plant

Working Principle

The Crawler Mobile Crushing Plant operates by transporting materials through its integrated vibrating feeder, which evenly feeds the raw materials into the main crusher. Depending on the configuration, the plant may use a jaw crusher, impact crusher, or cone crusher to crush the materials to the required size.

After primary crushing, the material may be transferred to a vibrating screen for classification. Oversized materials are returned to the crusher for further crushing, while the finished products are discharged through a conveyor belt for further processing or stockpiling.

Key components:

-

Vibrating Feeder

-

Primary Crusher (Jaw / Impact / Cone)

-

Vibrating Screen (optional)

-

Discharge Conveyor

-

Hydraulic System

-

Crawler Chassis

Crawler Mobile Crushing Plant

Performance Features

-

High Mobility: Equipped with a powerful tracked chassis, allowing easy movement across various terrains without the need for external transportation equipment.

-

Integrated Design: Combines crushing, screening, and conveying into one machine, reducing the need for additional equipment and on-site installation.

-

Flexible Configuration: Available with jaw crushers, impact crushers, or cone crushers, as well as optional screening units, to suit different production needs.

-

Hydraulic Control System: Fully hydraulic operations, including crushing, walking, and lifting functions, ensure stable performance and easy maintenance.

-

Quick Setup & Easy Operation: Rapid installation and commissioning; designed for user-friendly operation with remote control options.

-

Energy Efficient: Optimized power consumption ensures lower operating costs while maintaining high crushing efficiency.

-

Robust Structure: Heavy-duty frame and high-strength components ensure reliable operation under tough working conditions.

-

Environmental Protection: Equipped with dust suppression systems and noise reduction designs to comply with environmental standards.

Crawler Mobile Crushing Plant Categories and Models

1. Crawler Mobile Jaw Crusher

| Model | Max Feeding Size (mm) | Processing Capacity (t/h) | Main Crusher Model |

|---|---|---|---|

| CMC-106J | 630 | 90-320 | PE600×1060 or CJ106 |

| CMC-120J | 750 | 150-400 | PE750×1060 or CJ120 |

| CMC-150J | 1000 | 200-450 | PE900×1200 or CJ150 |

2. Crawler Mobile Impact Crusher

| Model | Max Feeding Size (mm) | Processing Capacity (t/h) | Main Crusher Model |

|---|---|---|---|

| CMC-1010I | 400 | 90-200 | PF1010 or CI1010 |

| CMC-1214I | 500 | 120-300 | PF1214 or CI1214 |

| CMC-1315I | 600 | 150-400 | PF1315 or CI1315 |

3. Crawler Mobile Cone Crusher

| Model | Max Feeding Size (mm) | Processing Capacity (t/h) | Main Crusher Model |

|---|---|---|---|

| CMC-100C | ≤160 | 80-180 | CS100 or HP100 |

| CMC-200C | ≤200 | 150-350 | CS200 or HP200 |

| CMC-300C | ≤250 | 200-500 | CS300 or HP300 |

4. Crawler Mobile Screening Plant

| Model | Screening Area (㎡) | Processing Capacity (t/h) | Number of Layers |

|---|---|---|---|

| CMS-1540S | 4.5 | 80-300 | Double or Triple Layers |

| CMS-1860S | 6.48 | 100-400 | Double or Triple Layers |

| CMS-2160S | 7.2 | 150-500 | Double or Triple Layers |

5. Crawler Mobile Feeding and Crushing Plant (with Heavy-Duty Vibrating Feeder)

| Model | Max Feeding Size (mm) | Processing Capacity (t/h) | Configuration |

|---|---|---|---|

| CMF-110G | 700 | 150-350 | Vibrating Feeder + Jaw Crusher |

| CMF-130G | 900 | 200-500 | Vibrating Feeder + Jaw Crusher |

Reviews

There are no reviews yet.