Plate Width: 1250 mm

Center Distance: 4 – 20 m

Max Feed Size: ≤800 mm

Capacity: 40 – 250 t/h

Motor Power: 11 kW

Working Principle

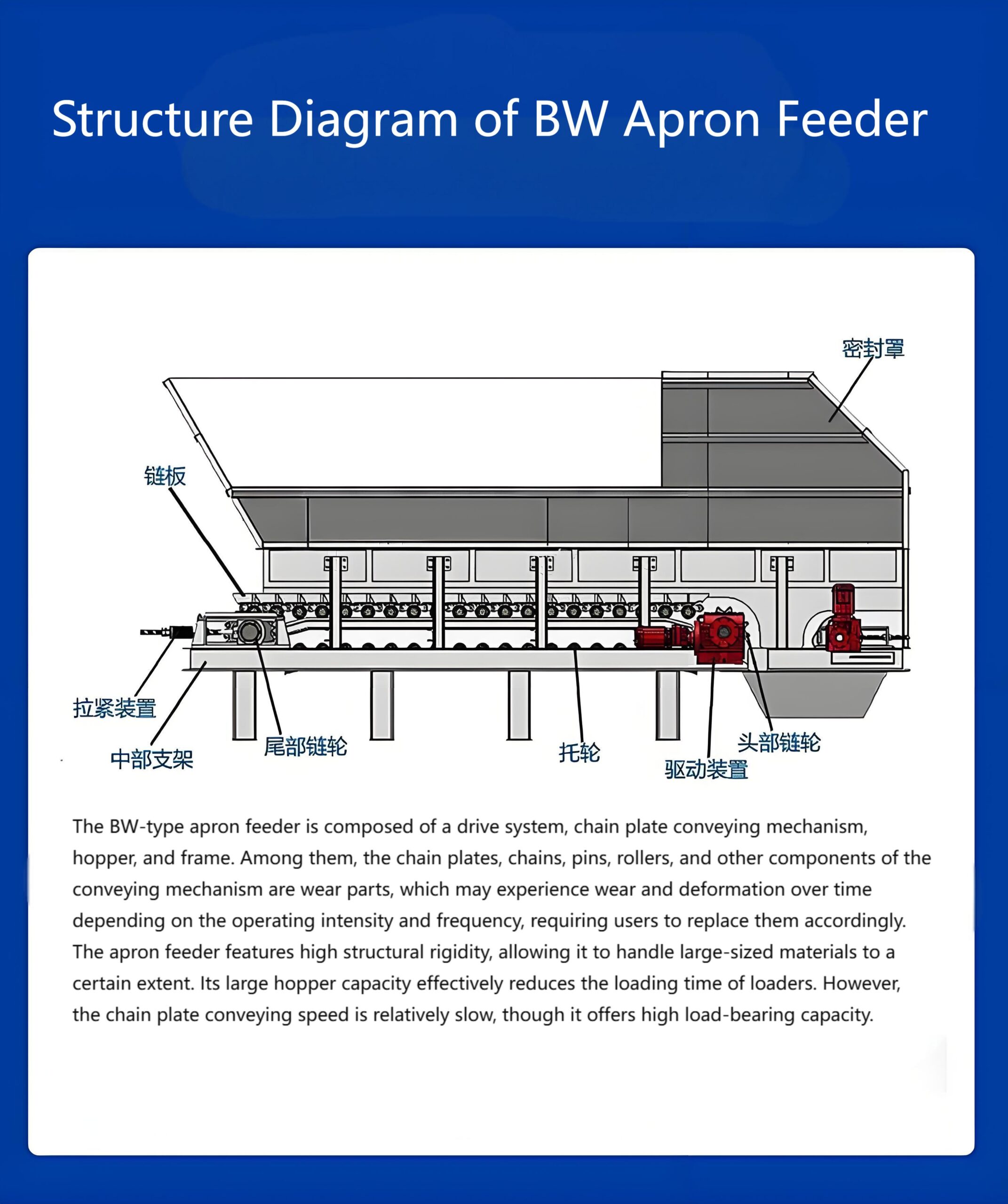

The BW chain plate feeder operates through a motor-driven sprocket system. The electric motor drives the reducer, which in turn rotates the drive sprockets. These sprockets engage with the chains connected to a series of overlapping steel apron plates. As the sprockets rotate, the chains pull the apron plates along the conveying path, thereby transporting materials from the hopper to downstream processing equipment.

During operation, materials stored in the hopper are discharged onto the moving apron plates, which steadily convey the materials forward. The feeding speed can be adjusted according to the process requirements to achieve accurate control of the material flow rate.

Performance Features

High Structural Rigidity: The feeder is capable of handling large-sized and heavy materials, ensuring stable and continuous operation even under severe conditions.

Large Hopper Capacity: The spacious hopper reduces the loading frequency of front loaders, increasing operational efficiency.

Excellent Wear Resistance: Key components such as apron plates, chains, pins, and rollers are made from high-strength wear-resistant materials for extended service life. These parts are easily replaceable when worn.

Stable and Uniform Feeding: Provides continuous and consistent material flow, preventing material blockage or sudden surges.

Adjustable Speed: Feeding speed can be regulated to meet different processing requirements.

High Load-Bearing Capacity: Designed to transport bulk materials with high density and large particle sizes.

Applications

Mining Industry

Cement Plants

Aggregate Production

Metallurgical Industry

Chemical Industry

Power Plants

Reviews

There are no reviews yet.