PCZ1510 Heavy-Duty Hammer Crusher

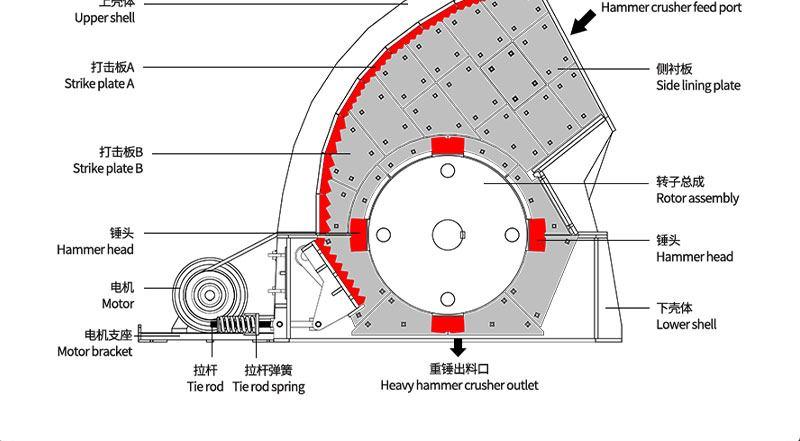

Working Principle

This crusher model is driven by a motor to rotate the rotor at high speed. The hammer repeatedly strikes and impacts the material entering the crushing chamber to achieve rapid crushing. When the material reaches the required particle size, it is discharged through the outlet; materials that do not meet the size continue to be crushed. The output particle size can be controlled by adjusting the gap between the impact plate and the hammer.

Performance Features

-

Compact structure with stable and reliable operation

-

Feed size ≤600mm, uniform finished product size

-

High crushing efficiency, one-time molding, large crushing ratio

-

Wear-resistant vulnerable parts, easy maintenance

-

360° rotatable hammer design to reduce the risk of breakage

-

Rotor disc made of 16Mn steel with embedded manganese steel protective sleeves to enhance wear resistance

Technical Parameters

| Parameter | Specification |

|---|---|

| Rotor Size | φ1500×1000 mm |

| Feed Opening | 1000×1000 mm |

| Feed Size | ≤700 mm |

| Processing Capacity | 160–210 t/h |

| Motor Power | 132×2 kW |

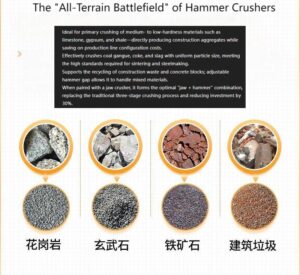

Application Advantages

Suitable for medium-sized stone plants, meeting the crushing requirements of larger particle sizes and higher processing capacities. Particularly suitable for primary crushing of sand and gravel aggregates.

Reviews

There are no reviews yet.