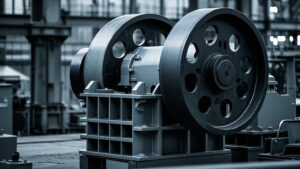

PE1000×1200 Jaw CrusherProduct Overview

The PE1000×1200 jaw crusher is a heavy-duty primary crushing machine, widely used in industries such as building materials, mining, chemical engineering, and road construction. It is specifically designed for coarse crushing of super-hard and high-strength materials like granite, ores, river pebbles, and hard limestone.

PE1000×1200 Jaw CrusherTechnical Specifications

| Item | Specification |

|---|---|

| Model | PE1000×1200 |

| Feed Opening Size (mm) | 1000 × 1200 |

| Maximum Feed Size (mm) | 850 |

| Discharge Adjustment Range (mm) | 195 – 265 |

| Processing Capacity (t/h) | 315 – 500 |

| Motor Power (kW) | 132 |

| Overall Dimensions (mm) | 3480 × 2876 × 3330 (actual operating dimensions) |

| Machine Weight | 52 tons |

| Color | Customizable |

Note: Some references list external dimensions as 5350 × 4280 × 3050 mm with a weight of 48 tons. The most commonly used configuration is listed above.

PE1000×1200 Jaw CrusherTypical Materials Crushed

Granite

Ores

River Pebbles

Hard Limestone

Basalt

Marble

Bluestone

Recycled construction waste (e.g., concrete, old bricks, wall materials, floor slabs, glass)

PE1000×1200 Jaw CrusherWorking Principle

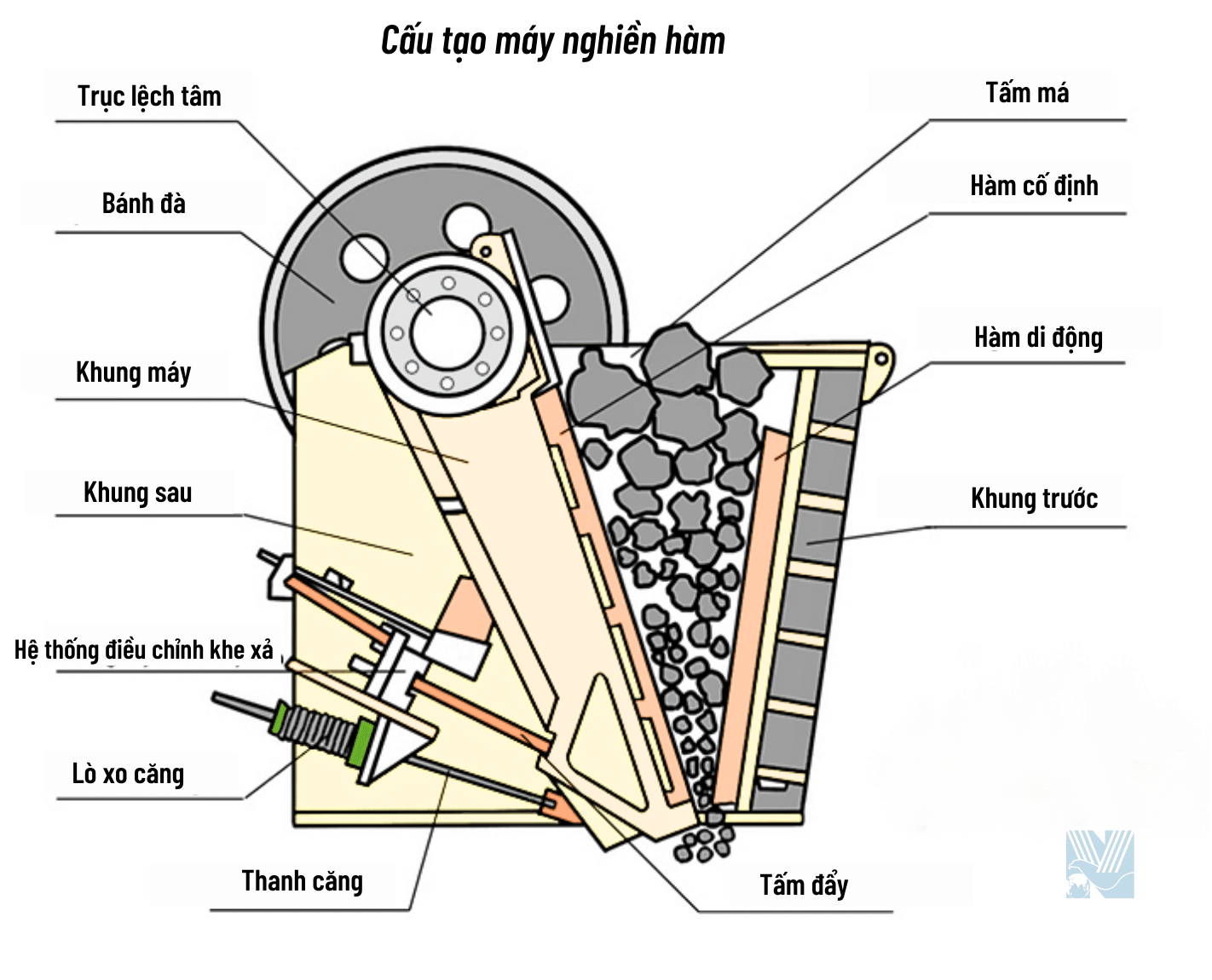

The PE1000×1200 jaw crusher operates by using a motor to drive the belt and pulley, which moves the movable jaw up and down. Material is crushed through compressive and splitting forces generated between the fixed and moving jaw plates. This mechanism is especially effective for breaking down large, hard materials into smaller sizes.

PE1000×1200 Jaw CrusherMaintenance and Servicing

Daily Maintenance: Regularly lubricate bearings, toggle plates, and other moving components. Monitor the wear of jaw plates and flip them periodically for extended use.

Installation: Must be mounted on a concrete foundation. Begin with no-load startup and gradually move to full-load testing.

Long-Term Maintenance: Annual servicing and major overhaul every two years are recommended to ensure continuous, efficient operation.

PE1000×1200 Jaw CrusherApplication Fields

Mining and mineral processing

Construction aggregate production

Chemical and metallurgical industries

Road and railway base material crushing

Recycled material processing (e.g., bricks, concrete, and glass)

Custom colors and configurations available. Contact us for technical consultation or equipment selection assistance.

Reviews

There are no reviews yet.