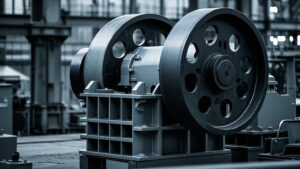

PE750×1060 Jaw Crusher — Product Overview & Working Principle

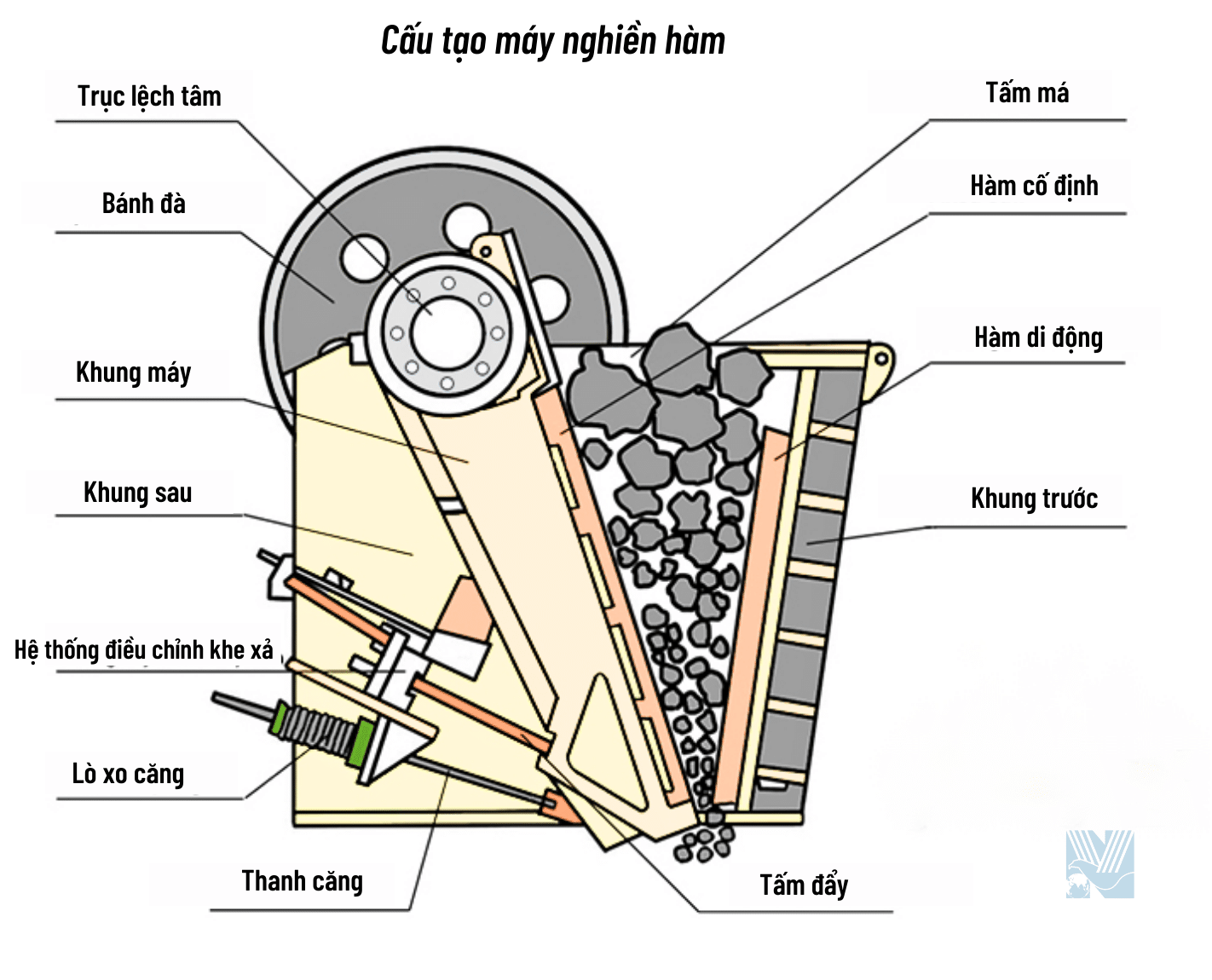

The PE750×1060 jaw crusher mainly consists of a frame, supporting device, working components (fixed jaw plate and movable jaw plate), transmission components (eccentric link, thrust plate, flywheel, eccentric shaft), safety devices, discharge port adjustment devices (wedge adjustment device, shim adjustment device), toggle plate, toggle seat, gap adjustment screw, and reset spring. The toggle plate also serves as a safety component.

Working Cycle

The jaw crusher operates in a cyclical motion, simulating the movement of animal jaws to crush material continuously. Its deep crushing chamber without dead zones improves feeding capacity and production output.

Key Features of PE750×1060 Jaw Crusher

-

Deep crushing chamber with no dead zones, enhancing feeding capacity and output.

-

High crushing ratio with uniform product size, low noise, and minimal dust emission.

-

Shim-type discharge port adjustment device — reliable, easy to use, with a large adjustment range to increase flexibility.

-

Safe and reliable lubrication system; easy replacement of parts with minimal maintenance effort.

-

Simple structure, reliable operation, and low operating costs.

-

Energy saving: single-machine energy savings of 15%–30%, system savings over 50%.

-

Wide discharge opening adjustment range to meet different user requirements.

-

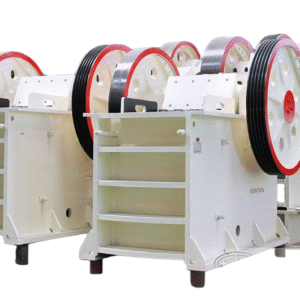

PE750×1060jaw Crusher

Parameter Value Model PE750×1060 Max. Feeding Size (mm) 630 Discharge Adjustment Range (mm) 80–140 Processing Capacity (t/h) 110–250 Motor Power (kW) 90 Machine Weight (t) Approx. 29 Dimensions (L×W×H, mm) 2660 × 2430 × 2800 Color Customizable PE750×1060jaw CrusherTypical Crushable Materials

Suitable for crushing high-hardness materials, such as:

-

Granite

-

Basalt

-

Diabase

-

Iron ore

-

Reviews

There are no reviews yet.